CleanSpace Respirators: Innovative Breathing Solutions for Comfort and Safety

Ever wondered how to breathe easy in a world full of pollutants? We’ve all been there, trying to find the perfect mask that doesn’t make us feel like we’re suffocating. Enter CleanSpace Respirators, the game-changer in personal protective equipment.

These nifty devices are like having a personal air purifier strapped to your face. But don’t worry, you won’t look like Darth Vader! CleanSpace Respirators are sleek, comfortable, and incredibly effective. They’re so good at their job, you might even forget you’re wearing one. Have you ever tried to drink coffee through a regular mask? It’s a disaster waiting to happen. With CleanSpace, you can sip your latte without fear of spillage.

We’ll dive into the world of CleanSpace Respirators, exploring their benefits and how they’re revolutionising workplace safety. Ready to take a breath of fresh air?

Key Takeaways

- CleanSpace Respirators are innovative powered air-purifying respirators (PAPRs) that offer superior protection against airborne contaminants with 99.97% filtration efficiency.

- These respirators feature a lightweight, compact design with one-button operation, making them comfortable and easy to use in various workplace settings.

- The AirSensit® Technology adapts airflow to match the user’s breathing, enhancing comfort and breathability during long periods of wear.

- CleanSpace Respirators are versatile, suitable for healthcare, industrial, and construction environments, offering clear communication and compatibility with other PPE.

- Compared to traditional respirators, CleanSpace models provide consistent protection, improved speech intelligibility, and higher user comfort ratings.

- Regular maintenance, including physical inspections and timely filter replacements, is crucial for optimal performance and longevity of CleanSpace Respirators.

What Are CleanSpace Respirators?

CleanSpace respirators are cutting-edge powered air-purifying respirators (PAPRs) that take personal protection to a whole new level. Imagine having your own personal bubble of clean air wherever you go – that’s what CleanSpace offers!

These nifty devices are like having a miniature air purifier strapped to your face. But don’t worry, they’re not as clunky as that sounds. In fact, they’re sleek, lightweight, and dare we say, rather stylish for protective gear.

Ever tried to drink your morning cuppa while wearing a mask? It’s a bit like trying to eat soup with a fork – frustrating and messy. CleanSpace respirators solve this age-old problem with their clear face mask design. You can sip your coffee, chat with colleagues, and even show off your pearly whites without compromising on safety.

But what makes these respirators truly special? It’s all in the tech, folks. They use something called AirSensit® Technology, which sounds fancy (and it is), but essentially means it filters out 99.97% of nasties from the air you breathe. That’s more effective than your gran’s home remedies for catching a cold!

Healthcare workers, in particular, have given these respirators a big thumbs up. They’ve rated them highly for safety, comfort, and ease of use. It’s like the holy trinity of respiratory protection!

Have you ever wondered what it would be like to have superhero-level protection against airborne threats? Well, wonder no more! CleanSpace respirators provide consistent and adequate respiratory protection, even during high-intensity activities. Chest compressions? No problem. Running a marathon? Okay, maybe not that extreme, but you get the idea.

Key Features of CleanSpace Respirators

CleanSpace Respirators offer cutting-edge features that set them apart in the world of respiratory protection. Let’s dive into the key elements that make these devices stand out.

Innovative Design

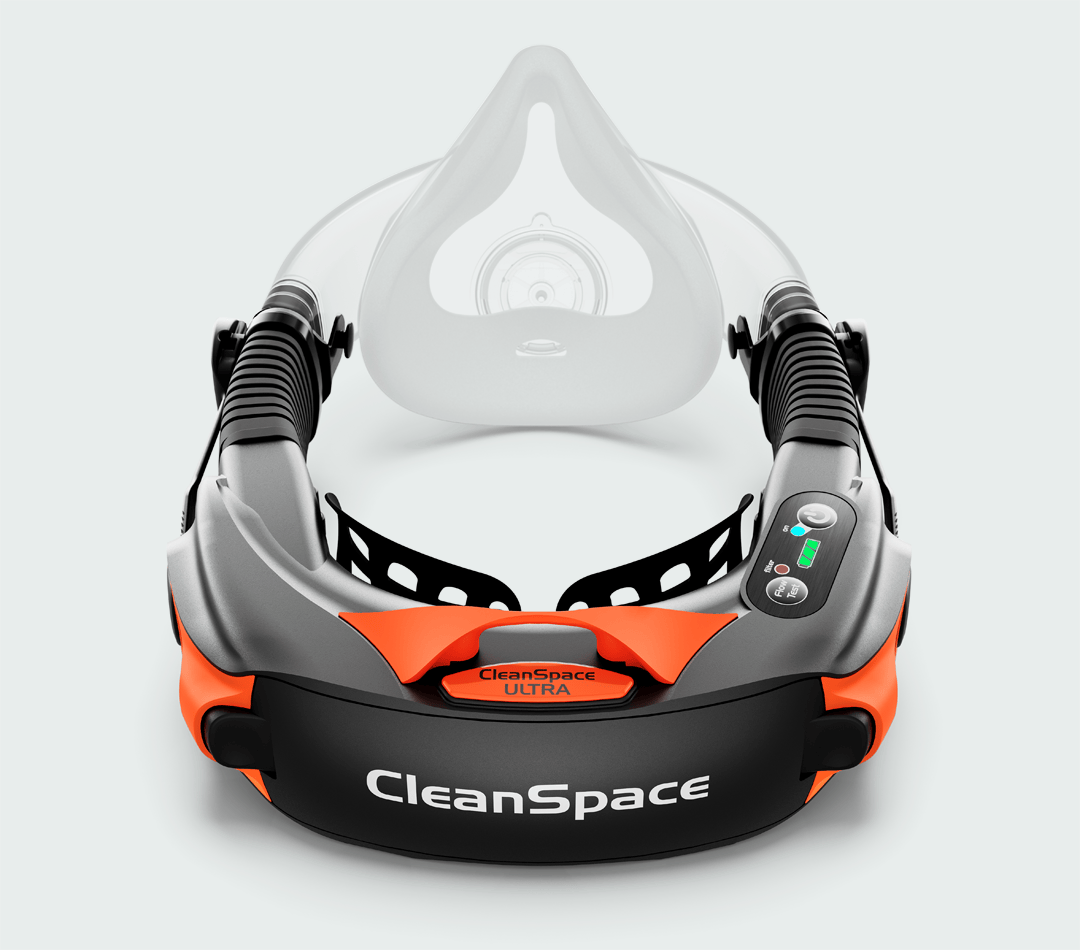

CleanSpace Respirators boast a compact and lightweight design, tipping the scales at just 350g for the HALO model and up to 500g for other variants. Imagine carrying a small bottle of water – that’s how light these respirators are! They’ve ditched the cumbersome hoses, belts, and waist-mounted battery packs, giving you the freedom to move about without feeling like you’re tangled in a web of equipment.

Ever fumbled with complicated gear? Well, CleanSpace has your back. Their one-button operation is so simple, you’ll wonder why all devices aren’t this user-friendly. It’s like they’ve taken a page from your smartphone’s book – easy to use, yet incredibly powerful.

Advanced Filtration Technology

When it comes to keeping the nasties out of your lungs, CleanSpace doesn’t mess about. Their proprietary AirSensit® Technology is like having a bouncer for your airways, turning away 99.97% of unwanted particles at the door. It’s equivalent to HEPA/P100 filters, which is just a fancy way of saying it’s really, really good at its job.

Think of it this way: if airborne contaminants were trying to gatecrash your personal air party, CleanSpace would be the eagle-eyed security guard spotting even the sneakiest of gate-crashers. From fine particles to aerosols, viruses to bacteria, these respirators have got your back… or should we say, your lungs?

Comfort and Fit

Ever worn a mask that felt like it was trying to smother you? CleanSpace Respirators are the opposite. They’re designed with your comfort in mind, fitting snugly without feeling suffocating. It’s like wearing a perfectly tailored suit, but for your face.

The clear face mask design is a game-changer. You can chat with your colleagues, and even flash a smile without having to remove your protection. It’s respiratory safety that doesn’t cramp your style.

Have you ever tried to communicate while wearing a traditional mask? It’s like playing a game of charades! With CleanSpace, you can speak clearly and be understood, making it perfect for those of us who work in teams or interact with others regularly.

Remember that time you tried to wear safety goggles with a traditional mask and ended up looking like a foggy-eyed alien? CleanSpace Respirators play nice with other PPE, so you can see clearly and stay protected from head to toe.

We’re all part of the breathing brigade, aren’t we? So why not breathe easier with a respirator that’s got your comfort, safety, and style all wrapped up in one nifty package? CleanSpace Respirators might just be the breath of fresh air you’ve been looking for in respiratory protection.

Benefits of Using CleanSpace Respirators

CleanSpace respirators offer superior protection and comfort compared to traditional masks. Let’s explore the key advantages that make these innovative devices stand out.

Enhanced Protection

CleanSpace respirators, including models like CleanSpace Work, CleanSpace EX, CleanSpace CST ULTRA, and CleanSpace HALO, provide top-notch safety benefits. These NIOSH-approved devices boast a 99.97% filtration efficiency, creating a robust barrier against airborne nasties.

Imagine having a personal forcefield that keeps out tiny troublemakers like respirable crystalline silica and airborne pathogens. That’s what CleanSpace respirators do! They’re like your lungs’ best mate, keeping them safe in high-risk environments such as hospitals, building sites, mines, and labs.

Have you ever wondered what it’d be like to have a superhero shield for your respiratory system? Well, with CleanSpace, you’re part of a community of breathers who’ve got just that!

Improved Breathability

We’ve all been there – struggling to catch our breath while wearing a stuffy mask. But CleanSpace respirators are different, thanks to their clever AirSensit® Technology. This nifty feature adapts the flow of filtered air to match your breathing rhythm, making it feel as natural as possible.

It’s like having a personal air DJ that mixes the perfect blend of clean air just for you. No more huffing and puffing like the Big Bad Wolf – with CleanSpace, you’ll breathe easy and comfortably, even during those high-intensity moments.

Here’s a chuckle for you: Why did the CleanSpace respirator win the dance competition? Because it had all the best moves and never ran out of breath!

By joining the CleanSpace club, you’re not just protecting yourself – you’re part of a movement towards smarter, more comfortable breathing solutions. So, are you ready to take a deep, clean breath and see what all the fuss is about? Need help choosing the right CleanSpace Respirator for your workplace? Contact our team for expert advice!

Applications and Industries

CleanSpace Respirators are versatile devices designed for use across various sectors. They offer high-level protection, comfort, and cost-effectiveness in diverse work environments.

Healthcare Settings

In healthcare, CleanSpace Respirators shine. They’re a godsend for medical professionals who need reliable protection without compromising communication. Imagine trying to explain a diagnosis through a muffled mask – it’s like talking underwater! But with CleanSpace, doctors and nurses can speak clearly while staying safe. These respirators are perfect for long shifts in hospitals, clinics, and care homes. They’re also ideal for dental procedures, where close contact is unavoidable.

Industrial Environments

CleanSpace Respirators are tough cookies in industrial settings. They’re ready to tackle anything from metal fabrication to chemical handling. In welding shops, they’re like a superhero’s shield against flying sparks and fumes. For those working in food processing, these respirators are a breath of fresh air – literally! They keep pesky flour dust and other particles at bay.

And let’s not forget about the mining and quarry crews. CleanSpace Respirators are their trusty sidekicks in the fight against dust and debris. They’re also a hit in construction, where concrete dust is as common as bad jokes on a building site.

We’re all part of the clean air club now. So, what’s your workplace like? Do you need a respiratory superhero to swoop in and save the day?

Comparing CleanSpace to Traditional Respirators

Ever wondered how CleanSpace respirators stack up against their old-school counterparts? Let’s dive in and explore the differences that make CleanSpace a breath of fresh air in the world of respiratory protection.

Respiratory Protection

CleanSpace respirators, offer consistent and adequate protection levels. Quantitative fit tests and simulated workplace protection factor studies have shown that these respirators maintain their effectiveness at rest, during, and after physical activities. Even when performing chest compressions, the protection remains steady, whether the power is on or off. It’s like having a personal bodyguard for your lungs that never takes a break!

Communication Performance

Traditional respirators can be a real conversation killer, decreasing speech intelligibility by 1% to 17%. That’s like trying to chat with a mouthful of marbles! CleanSpace HALO, on the other hand, meets the NIOSH minimum standard for speech intelligibility. Want to take your communication game to the next level? Adding wireless communication headsets makes conversations crystal clear. No more shouting “Can you hear me now?” across the room!

Usability and Comfort

When it comes to usability and comfort, CleanSpace respirators are top-notch. They’re like the comfy trainers of the respirator world – you might forget you’re even wearing them! Users consistently rate these respirators highly for their ease of use and comfort.

Have you ever tried wearing a traditional respirator for a long shift? It’s about as fun as wearing a cardboard box on your face. CleanSpace respirators, however, are designed with the user in mind, making those long hours more bearable.

So, are you ready to join the CleanSpace revolution? Together, we can breathe easier and work smarter. After all, who said respiratory protection can’t be comfortable and effective at the same time?

Maintenance and Care Tips

Taking care of your CleanSpace Respirator is like tending to a loyal pet – it needs regular attention to keep purring along smoothly. Let’s dive into some essential maintenance tips that’ll keep your breathing buddy in tip-top shape.

Physical Condition

Picture your respirator as a superhero’s mask – it needs to be in prime condition to fight off those pesky airborne villains. Give it a once-over regularly, looking for any battle scars like cracks or tears. Check the face piece, head straps, and other bits and bobs for signs of wear and tear. Remember, a well-maintained respirator is a happy respirator!

Ever wondered what your respirator would say if it could talk? It might just thank you for keeping an eye on its attachments and head harness. These parts work hard to keep you safe, so show them some love by checking for any excessive wear.

Filter Maintenance

Filters are the unsung heroes of your respirator. They’re like tiny bouncers, keeping unwanted particles out of your personal air party. But even bouncers need a break sometimes.

Here’s a fun fact: you can’t wash your filters in the sink like your favourite coffee mug. Once they’ve done their job, it’s time for them to retire. Replace them if they’ve been damaged, had an unexpected shower, or if your respirator starts beeping and flashing like a disco ball (that’s the filter change alert, by the way).

Last but not least, make sure you’re using the right filter for the job. It’s like picking the right tool from your toolbox – you wouldn’t use a hammer to screw in a lightbulb, would you? Stick to CleanSpace filters for your CleanSpace Respirator. They’re made for each other, like peanut butter and jelly!

Conclusion

CleanSpace Respirators represent a significant leap forward in respiratory protection technology. We’ve explored their innovative features advanced filtration capabilities and versatile applications across various sectors. These devices offer a perfect blend of safety comfort and style making them an ideal choice for professionals and individuals alike. By choosing CleanSpace you’re not just investing in a respirator but embracing a smarter healthier way of breathing. Join the growing community of CleanSpace users and experience the future of respiratory protection today.

Frequently Asked Questions

What are CleanSpace Respirators?

CleanSpace Respirators are innovative personal air purifiers designed for comfortable breathing in polluted environments. They are advanced powered air-purifying respirators (PAPRs) that create a personal bubble of clean air, combining style with functionality.

How effective are CleanSpace Respirators in filtering air?

CleanSpace Respirators are highly effective in filtering air. They use AirSensit® Technology, which filters out 99.97% of airborne contaminants. This technology acts as a security guard for the lungs, effectively removing harmful particles from the air you breathe.

Are CleanSpace Respirators comfortable to wear?

Yes, CleanSpace Respirators are designed for comfort. They are compact and lightweight, with the HALO model weighing just 350g. The respirators fit snugly without suffocating, allowing for clear communication and compatibility with other PPE. Users find them far more comfortable for extended wear compared to traditional options.

How do CleanSpace Respirators compare to traditional masks?

CleanSpace Respirators offer superior protection and comfort compared to traditional masks. They provide consistent protection levels during various activities, including strenuous tasks. Unlike traditional respirators, CleanSpace models maintain speech clarity and can be enhanced with wireless communication headsets.

In which industries are CleanSpace Respirators particularly useful?

CleanSpace Respirators are versatile and useful in various sectors. They are particularly beneficial in healthcare, where clear communication is crucial during long shifts and close-contact procedures. They’re also ideal for industrial environments such as welding, food processing, mining, and construction, protecting against hazards like sparks, fumes, and dust.

How do I maintain my CleanSpace Respirator?

Maintain your CleanSpace Respirator by regularly checking its physical condition, particularly the face piece and head straps, for signs of wear and tear. Replace filters as recommended and clean the device according to the manufacturer’s instructions. Proper maintenance ensures the respirator’s longevity and effectiveness.