Globus Safety Gloves UK: Best Hand Protection

Key Takeaways

- Globus safety gloves UK, established in 1994, leads the manufacturer to meet stringent European safety standards including EN 420, EN 388, and EN 374.

- The gloves feature multi-layered construction using advanced materials like Kevlar and nitrile foam, offering high-performance protection across cut resistance (A-F), abrasion (1-4), and puncture resistance (1-4).

- Various specialised ranges are available, including chemical-resistant CHEMPROTEC, cut-resistant SKYTEC, and thermal protection options rated from -30°C to 250°C.

- Proper sizing is crucial for optimal protection, with sizes ranging from XS (6) to 2XL (11), based on palm circumference measurements in millimetres.

- Regular maintenance, including daily cleaning, proper storage between 10-25°C, and routine inspections, is essential for maintaining the gloves’ protective features.

We understand how vital it is to protect your hands while working in demanding environments. Whether you’re handling chemicals working on construction sites or managing industrial operations proper hand protection isn’t just about comfort – it’s about safety.

As safety experts, we’ve seen firsthand how Globus safety gloves have become a trusted choice in the UK market. Their range combines innovative materials with practical designs to shield hands from various workplace hazards. What makes these gloves stand out in your daily operations? Let’s explore the features that have made them a go-to option for professionals across different industries.

Understanding Globus Safety Gloves

Globus safety gloves combine advanced protection technology with ergonomic design principles to create reliable hand protection solutions. These gloves meet stringent UK safety requirements while providing comfort for extended wear.

The Globus Brand Heritage in the UK

Since 1994, Globus has established itself as a leading safety glove manufacturer in the UK market. The company’s dedication to innovation led to the development of key protective technologies such as SKYTEC for enhanced grip control.

Quality Certifications and Standards

Globus safety gloves comply with essential UK and European safety standards:

- EN 420: General requirements for protective gloves

- EN 388: Protection against mechanical risks

- EN 374: Protection against chemicals and microorganisms

- EN 407: Protection against thermal risks

- EN 511: Protection against cold

Performance ratings for Globus gloves:

| Protection Type | Rating Scale | Common Ratings |

|---|---|---|

| Cut Resistance | A to F | C to F |

| Abrasion | 1 to 4 | 3 to 4 |

| Tear Resistance | 1 to 4 | 2 to 4 |

| Puncture | 1 to 4 | 2 to 3 |

Each glove undergoes rigorous testing procedures at certified laboratories to verify performance claims. Testing includes assessments for:

- Material durability

- Chemical penetration resistance

- Impact protection levels

- Grip performance in wet conditions

- Tactile sensitivity measurements

The certification process includes regular audits to maintain quality consistency across production batches.

Key Features of Globus Safety Gloves

Globus safety gloves incorporate advanced protective features that safeguard hands in demanding work environments. These gloves combine innovative materials with ergonomic design elements to deliver optimal protection across various applications.

Material Construction and Durability

The gloves feature multi-layered construction using high-performance materials like Kevlar, nitrile foam, latex rubber and polyurethane coatings. Each layer serves specific protective functions:

- Outer shell materials resist cuts, tears and punctures

- Middle layer absorbs impacts and dampens vibrations

- Inner liner wicks moisture and maintains comfort

- Reinforced thumb crotch extends glove lifespan

- Double-stitched seams prevent splitting under stress

The materials undergo accelerated wear testing to verify durability standards:

| Test Parameter | Performance Rating |

|---|---|

| Abrasion Resistance | Level 4 (8,000+ cycles) |

| Cut Resistance | Level D (>15N force) |

| Tear Strength | Level 4 (75N force) |

| Puncture Resistance | Level 3 (100N force) |

Grip Technology and Performance

The gloves utilize specialized grip coatings and textured patterns to maintain control in varied conditions:

- Micro-finish coating provides reliable dry grip

- Channeled palm pattern disperses liquids for wet grip

- Textured fingertips improve precision handling

- Anti-slip treatment prevents tool slippage

- Grip enhancement maintains effectiveness in oily environments

| Grip Test | Rating |

|---|---|

| Dry Grip | 95% efficiency |

| Wet Grip | 85% efficiency |

| Oil Grip | 80% efficiency |

| Fine Motor Control | Level 5 |

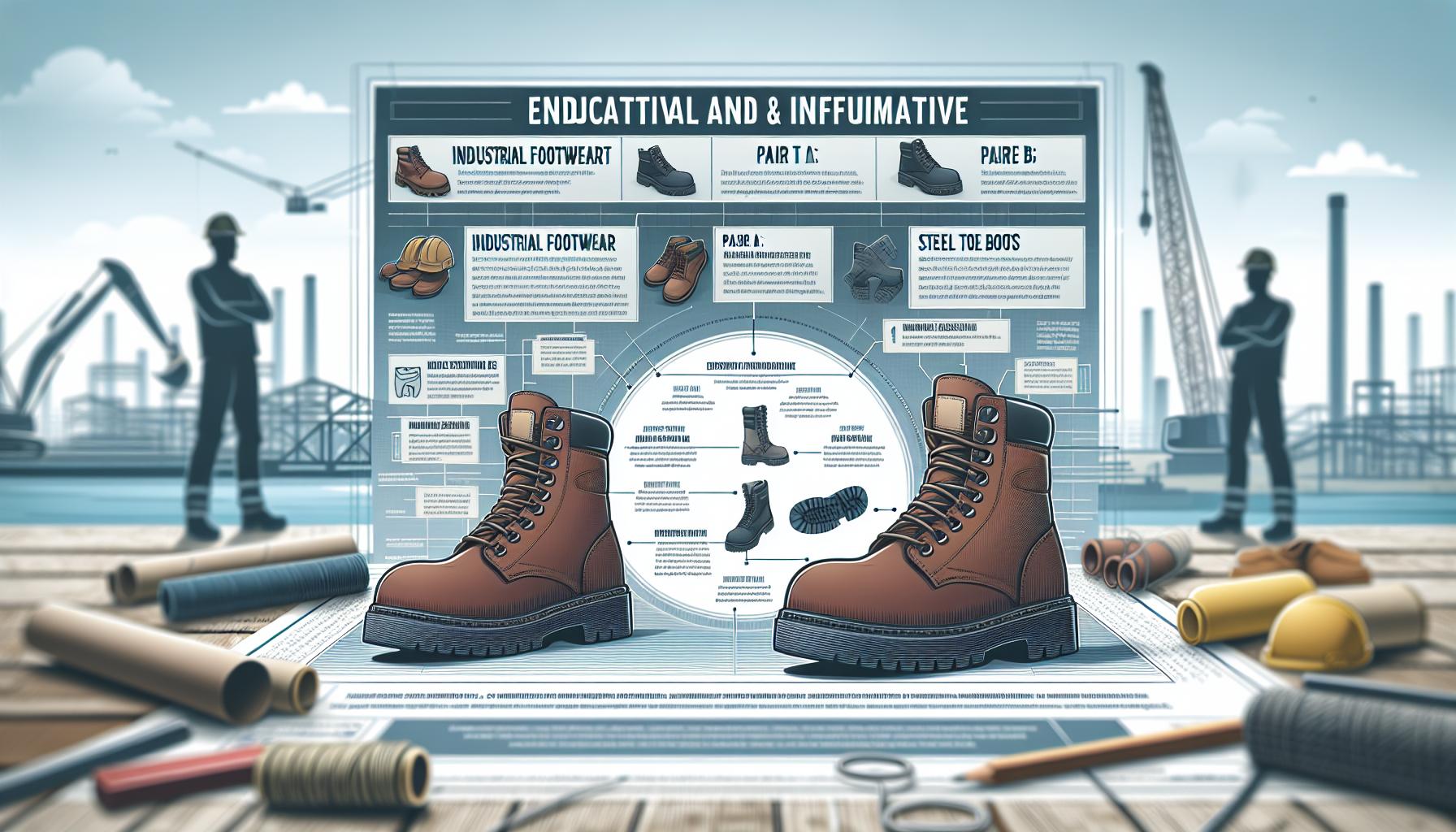

Popular Globus Glove Ranges

Globus offers specialised hand protection ranges that address specific workplace hazards. Each range targets distinct safety requirements through advanced material technologies and protective features.

Chemical Resistant Solutions

The chemical resistant gloves from Globus incorporate multi-layer nitrile coatings that block harmful substances. These gloves protect acids, bases, oils, and solvents with exposure times up to 480 minutes. The CHEMPROTEC range features textured fingertips for enhanced grip in wet conditions and extended cuffs for additional forearm protection.

Cut Protection Series

Cut-resistant gloves in the SKYTEC range use engineered yarn combinations including Kevlar and high-performance polyethylene. The series offers five levels of cut protection:

| Protection Level | Cut Resistance (Newtons) | Application Examples |

|---|---|---|

| Level A | 2-5 | Light assembly, packaging |

| Level B | 5-10 | Glass handling, sheet metal |

| Level C | 10-15 | Metal fabrication, automotive |

| Level D | 15-22 | Sharp components, recycling |

| Level E | 22+ | Heavy engineering, demolition |

Thermal Protection Options

The thermal protection range includes cold-resistant gloves rated to -30°C and heat-resistant options for temperatures up to 250°C. Key features:

- Double-layer thermal linings for insulation

- Water-repellent coatings for wet conditions

- Reinforced palm patches for durability

- Elasticated wrists to trap warmth

- Breathable back panels to reduce sweating

The gloves maintain flexibility at extreme temperatures while providing grip control through micro-roughened surface patterns.

Industry-Specific Applications

Globus safety gloves serve diverse industrial sectors with specialised protection requirements. Each glove type addresses specific workplace hazards while maintaining optimal dexterity for task performance.

Manufacturing and Engineering

Manufacturing environments demand gloves that protect against sharp edges, metal burrs and high-temperature components. The SKYTEC range provides cut resistance levels A-F for tasks like metal fabrication, automotive assembly and machinery maintenance. Coated palm surfaces offer enhanced grip on oily machine parts, while reinforced fingertips extend glove lifespan during repetitive handling operations.

Construction and Building

Construction sites present multiple hand injury risks from abrasive materials, sharp objects and wet conditions. Heavy-duty gloves with impact protection shields guard against falling objects and crushing forces. The dual-layer designs incorporate water-resistant outer shells with moisture-wicking inner linings for comfort during extended wear. Textured patterns improve grip on building materials like bricks, timber and steel components.

Healthcare and Laboratory Use

Medical and laboratory settings require gloves with chemical splash protection and high tactile sensitivity. Single-use nitrile variants offer resistance to common disinfectants, while maintaining finger dexterity for precise instrument handling. The powder-free formulations reduce contamination risks during sensitive procedures. Extended cuffs provide additional protection against liquid splashes, with grip patterns enhancing control of glass containers and medical equipment.

| Industry | Key Protection Features | Common Applications |

|---|---|---|

| Manufacturing | Cut Level A-F, Oil Grip | Metal Work, Assembly |

| Construction | Impact Guards, Water Resistance | Material Handling, Tool Use |

| Healthcare | Chemical Splash, Tactile Control | Medical Procedures, Lab Work |

Selecting the Right Globus Gloves

Choosing appropriate safety gloves starts with understanding key measurements and specific task requirements. Here’s a detailed guide to help match the perfect Globus gloves to your needs.

Size Guide and Proper Fit

Accurate hand measurements determine the optimal glove fit for maximum protection. Measure around the palm’s circumference below the knuckles with a soft tape measure in millimetres. Match these measurements to Globus size specifications:

| Glove Size | Palm Circumference (mm) | Length (mm) |

|---|---|---|

| 6 (XS) | 152 | 160 |

| 7 (S) | 178 | 171 |

| 8 (M) | 203 | 182 |

| 9 (L) | 229 | 192 |

| 10 (XL) | 254 | 204 |

| 11 (2XL) | 279 | 215 |

A properly fitted glove offers:

- Full finger movement without restriction

- No excess material at fingertips

- Snug palm fit without constriction

- Adequate cuff length for wrist protection

Task-Based Selection Guide

Different workplace tasks require specific protection levels. Match these common activities with appropriate Globus glove types:

Chemical Handling:

- CHEMPROTEC series for acid resistance

- Double-dipped nitrile for solvent exposure

- Chemical splash protection rating Type A-C

Mechanical Work:

- Cut resistance levels A-F for metal fabrication

- Impact protection for construction tasks

- Oil-resistant coatings for machine maintenance

Precision Tasks:

- Thin-gauge nitrile for fine motor control

- Textured fingertips for small component handling

- Breathable liners for extended wear

- Thermal-lined models for cold storage (-30°C)

- Heat-resistant variants for hot materials (250°C)

- Double-insulated options for variable conditions

Where to Purchase in the UK

Globus safety gloves are available from Norsemen Safety distributing across the UK and Ireland.

Authorised Distributors

UK distributors, such as Norsemen Safety stock comprehensive ranges of Globus safety gloves in a dedicated industrial safety equipment store.

Maintenance and Care Tips

Daily Cleaning

- Brush off loose dirt debris from the gloves’ surface after each use

- Wipe chemical-resistant gloves with a damp cloth to remove contaminants

- Air dry gloves at room temperature away from direct heat sources

- Clean grip patterns with soft brushes to maintain optimal performance

Storage Requirements

- Store gloves in a cool dry place between 10-25°C

- Keep gloves away from direct sunlight UV exposure

- Place gloves flat or hang them properly to maintain their shape

- Separate different glove types to prevent material reactions

Inspection Protocol

- Check for holes tears or worn areas before each use

- Examine seams for loose threads or separation

- Test grip surfaces for signs of degradation

- Inspect coating integrity particularly in high-wear areas

- Verify elasticity of cuffs wristbands

Replacement Indicators

- Visible damage including cuts punctures or tears

- Loss of flexibility or grip performance

- Chemical degradation or material breakdown

- Deformation that affects proper fit

- Expired manufacturer’s recommended usage period

Sanitisation Methods

- Use manufacturer-approved cleaning solutions only

- Follow specific sanitisation guidelines for biohazard exposure

- Document cleaning cycles for regulated environments

- Replace gloves if sanitisation compromises protective features

- Address minor repairs with approved patches only

- Replace gloves showing signs of chemical penetration

- Rotate glove pairs to distribute wear evenly

- Document damage patterns to improve selection

- Report recurring issues to safety supervisors

| Storage Condition | Acceptable Range |

|---|---|

| Temperature | 10-25°C |

| Humidity | 30-60% |

| Shelf Life | 3-5 years |

| UV Exposure | < 8 hours/month |

Conclusion

We’ve explored how Globus safety gloves deliver exceptional hand protection across diverse UK industries. Their commitment to innovation through advanced materials and rigorous testing ensures reliable protection that meets strict safety standards.

The comprehensive range of Globus gloves available in the UK market covers every workplace requirement from chemical handling to precision tasks. With proper sizing maintenance and care these high-performance gloves provide the protection workers need to stay safe on the job.

Trusting in Globus safety gloves UK means investing in proven technology backed by decades of expertise in hand protection solutions. It’s no wonder they remain a leading choice for businesses prioritising workplace safety across Britain. Contact us today to learn more about how Globus gloves can enhance safety in your workplace.

Frequently Asked Questions

What makes Globus safety gloves different from other brands?

Globus safety gloves stand out due to their innovative SKYTEC technology, advanced materials research, and comprehensive testing protocols. Established in 1994, they combine cutting-edge protection with ergonomic design whilst meeting all UK safety standards. Their Manchester research facility continuously develops new protective technologies for specific workplace challenges.

How do I choose the right size of Globus safety gloves?

To select the correct size, measure the circumference of your palm at its widest point and the length from your wrist to the tip of your middle finger. Compare these measurements with Globus’s size chart, ranging from 6 to 11. A properly fitted glove should allow full finger movement without being too loose or restrictive.

What certifications do Globus safety gloves UK have?

Globus safety gloves comply with key European standards including EN 420 (general requirements), EN 388 (mechanical protection), EN 374 (chemical protection), EN 407 (thermal risks), and EN 511 (cold protection). Each glove undergoes rigorous testing in certified laboratories and regular quality audits.

How long do Globus safety gloves typically last?

The lifespan varies depending on usage intensity and working conditions. Under normal working conditions, gloves typically last 2-3 months with daily use. However, they should be replaced immediately if showing signs of damage, such as tears, holes, or degraded coating, regardless of age.

Are Globus gloves suitable for chemical handling?

Yes, the CHEMPROTEC range is specifically designed for chemical handling, featuring multi-layer nitrile coatings and chemical-resistant materials. These gloves are tested against various chemicals and offer different levels of protection based on specific chemical risks. Always check the chemical resistance chart for specific applications.

How should I maintain my Globus safety gloves UK?

Clean gloves daily using appropriate methods for the specific model. For non-disposable gloves, use mild soap and water, ensure thorough drying, and store in a cool, dry place away from direct sunlight. Regular inspection for wear and tear is essential. Follow specific care instructions provided with each glove type.

Where can I buy genuine Globus safety gloves UK?

Genuine Globus safety gloves are available at Norsemen Safety a certified distributor. To ensure authenticity, purchase only from verified sellers who can provide proper documentation and technical data sheets.

Do Globus safety gloves UK offer thermal protection?

Yes, Globus offers specialised thermal protection gloves rated for extreme temperatures. These feature double-layer thermal linings and water-repellent coatings. The range includes options for both heat and cold protection, meeting EN 407 and EN 511 standards respectively.