Safety Footwear Belfast UK: Top Work Boots & Protection Guide

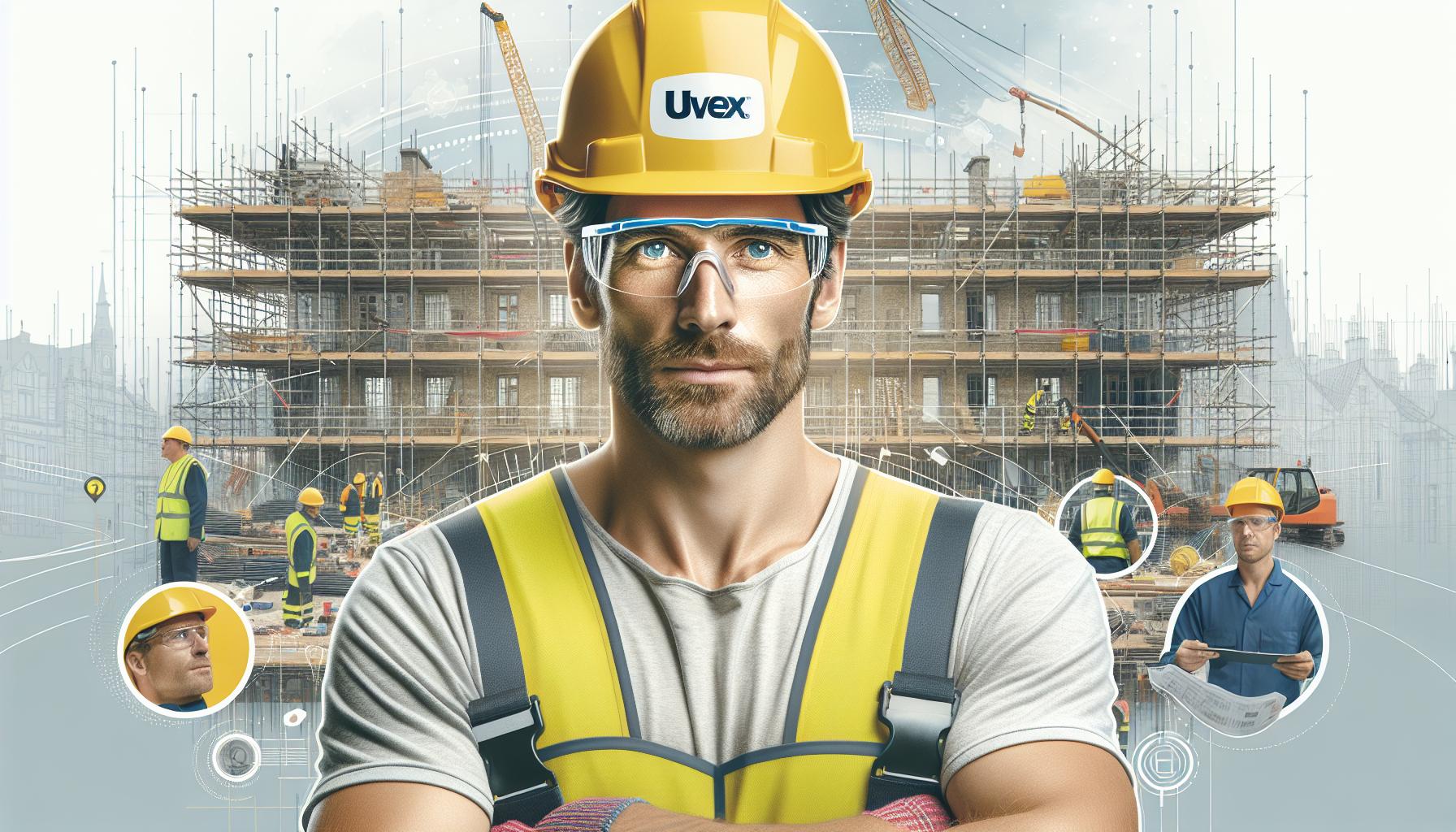

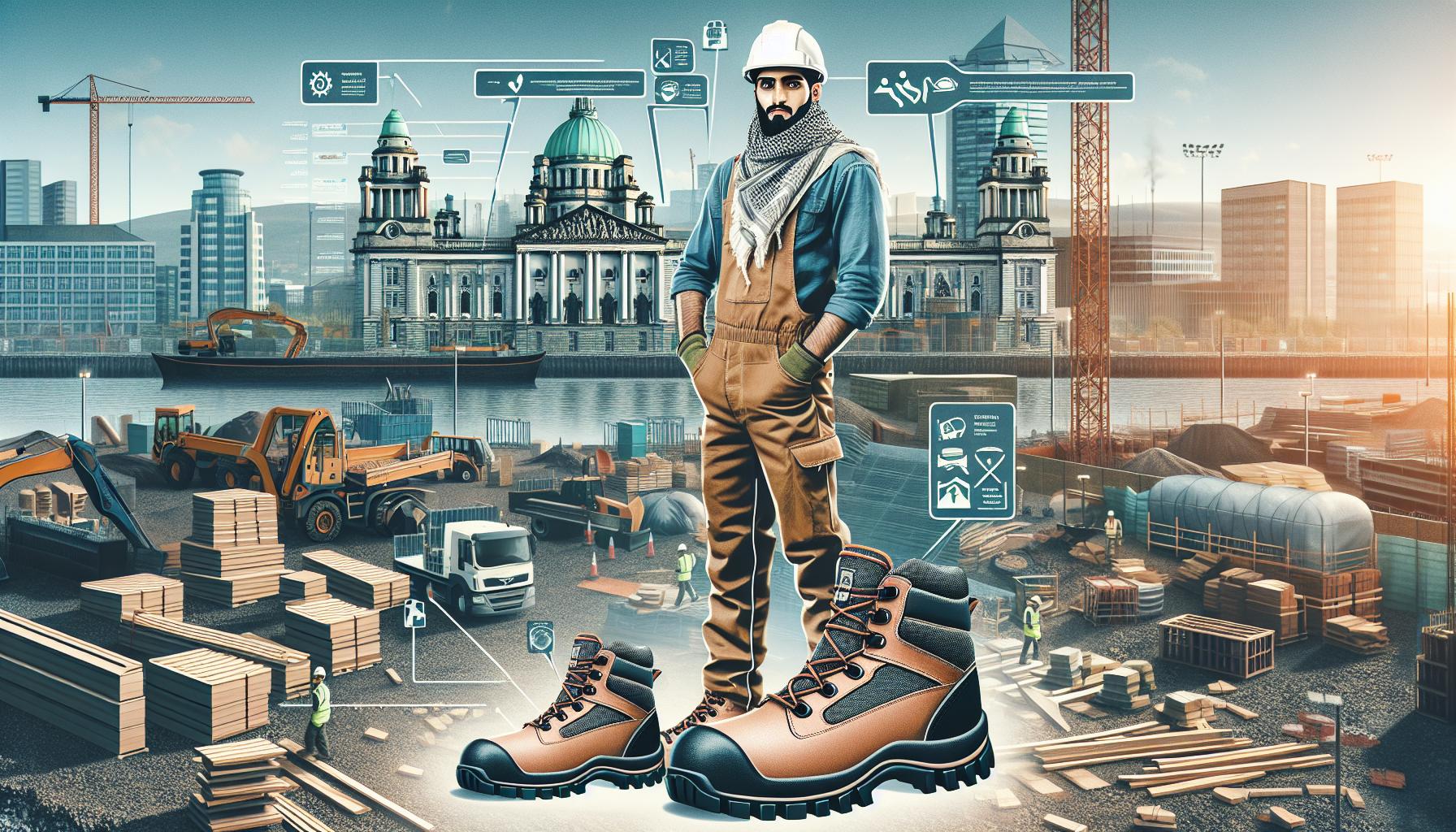

Looking for safety footwear Belfast UK? Norsemen Safety understand how vital it is to protect your feet while working. Whether you’re in construction, manufacturing or any industrial setting, having the right safety shoes can make all the difference in your workday comfort and protection.

Norsemen Safety has been supplying top-quality PPE and safety equipment across the UK, Northern Ireland and the Republic of Ireland for years. Our extensive range of safety footwear meets strict industry standards, giving you peace of mind while you focus on your work. What specific safety features do you need in your work boots?

Feel free to explore our collection of safety footwear that’s built to last. From steel toe caps to slip-resistant soles, we’ll help you find the perfect pair that matches your workplace requirements and keeps you safe on the job.

Key Takeaways -Safety Footwear Belfast UK

- Safety footwear Belfast UK must comply with EN ISO 20345:2011 standards, offering protection levels from S1 to S5 for different workplace requirements

- Essential safety features include steel toe caps (200-joule impact protection), slip-resistant soles, and penetration resistance, varying by industry requirements

- Premium safety boots offer advanced features like waterproof membranes and anti-fatigue technology, whilst budget options provide basic protection starting from £25

- Proper fitting is crucial – allow 1.5cm toe space, test with work socks, and ensure no heel slippage for optimal comfort and protection

- Regular maintenance, including daily cleaning and bi-monthly leather conditioning, significantly extends the lifespan of safety footwear, with full replacement recommended every 12-18 months

Understanding Safety Footwear Requirements in Belfast UK

Safety footwear standards protect workers in Belfast’s industrial sectors through specific regulations for foot protection equipment. Here’s a comprehensive look at the requirements for workplace footwear safety.

UK Safety Standards and Regulations -Safety footwear Belfast UK

EN ISO 20345:2011 sets the primary safety footwear standards in Belfast. The regulations establish five protection levels:

- S1 includes antistatic properties closed heel slip-resistant soles

- S2 adds water resistance to S1 requirements

- S3 incorporates penetration resistance midsoles with S2 features

- S4 applies to waterproof rubber boots with safety toes

- S5 combines S4 features with puncture-resistant soles

Additional markings indicate specific protections:

- P: Penetration resistance

- C: Conductive properties

- A: Antistatic properties

- HI: Heat insulation

- CI: Cold insulation

Industry-Specific Requirements

Different Belfast industries require specific safety footwear features:

Construction:

- Steel toe caps rated for 200-joule impact protection

- Penetration-resistant midsoles

- Slip-resistant outsoles for varied surfaces

Manufacturing:

- Metatarsal protection for heavy machinery areas

- Chemical-resistant materials in processing plants

- Heat-resistant soles for high-temperature environments

- Lightweight designs for extended walking periods

- Shock-absorbing heel sections

- Anti-fatigue cushioning systems

| Industry | Protection Level | Essential Features |

|---|---|---|

| Construction | S3 | Steel toe cap, penetration resistance |

| Manufacturing | S2/S3 | Chemical resistance, heat protection |

| Logistics | S1/S2 | Shock absorption, comfort features |

Top Safety Footwear at Norsemen Safety in Belfast

Norsemen Safety offers multiple many ways to purchase safety footwear that meets UK workplace standards.

Industrial Suppliers of Safety footwear Belfast UK

Norsemen Safety in Belfast specialise in comprehensive safety footwear ranges. Their offerings include:

- Extended size ranges including half sizes

- Advanced protection features like metatarsal guards

- Specialist footwear for specific industries

- Bulk order capabilities

- Direct delivery services

- Expert fitting assistance

- PPE package combinations

Popular Safety Boot Brands Available in Belfast

Norsemen Safety Belfast’s safety footwear market features an extensive selection of trusted brands that meet UK safety standards. Our comprehensive range includes options for every budget and workplace requirement.

Premium Safety Footwear Options

Premium safety boots combine superior protection with exceptional comfort and durability. These high-end options include:

- Waterproof leather uppers with breathable membranes

- Advanced cushioning systems for extended wear

- Impact-resistant toe caps exceeding safety standards

- Anti-fatigue technology for all-day comfort

- Heat-resistant soles rated up to 300°C

- Electrical hazard protection features

Budget-Friendly Alternatives

Cost-effective safety boots offer essential protection without compromising on safety standards:

- Basic steel toe cap protection

- Oil-resistant rubber soles

- Standard shock absorption

- Water-resistant uppers

- Slip-resistant tread patterns

- Basic comfort padding

All safety footwear options, regardless of price point, meet the minimum EN ISO 20345:2011 safety requirements for workplace protection.

Choosing the Right Safety Footwear

Selecting appropriate safety footwear combines proper sizing with essential protection features. Let’s explore the key factors to consider when purchasing safety boots in Belfast.

Comfort and Fit Considerations

Safety boots must fit perfectly for all-day comfort at work. Here’s what to check during fitting:

- Measure feet in the afternoon when they’re naturally swollen

- Leave 1.5cm space between toes and boot tip

- Test boots with work socks for accurate sizing

- Walk around for 5-10 minutes to assess comfort

- Check for pressure points around ankle bones

- Confirm heels don’t slip while walking

- Try both boots as feet can differ in size

Protection Features of Safety footwear Belfast UK

Safety footwear offers various protection levels based on workplace hazards:

| Protection Type | Feature Description | Common Applications |

|---|---|---|

| Toe Protection | 200J impact resistance | Construction sites |

| Slip Resistance | SRC rated outsoles | Wet industrial floors |

| Metatarsal Guard | Top-foot protection | Heavy manufacturing |

| Puncture Protection | Steel/composite midsole | Building sites |

| Water Resistance | Waterproof membrane | Outdoor work |

Protection ratings include:

- SB – Basic safety with toe protection

- S1 – SB plus antistatic properties

- S2 – S1 plus water resistance

- S3 – S2 plus puncture protection

- S4/S5 – Wellington-style boots with varying protection

- Steel toe caps protect against falling objects

- Anti-static properties prevent static buildup

- Heat-resistant soles withstand up to 300°C

- Slip-resistant treads grip on varied surfaces

- Waterproof membranes keep feet dry in wet conditions

Maintenance and Care Tips

Daily Cleaning

Regular cleaning extends safety footwear lifespan. Remove dirt with a soft brush after each use. Wipe leather uppers with a damp cloth to remove dust particles. Clean the soles with warm water to remove trapped debris. Allow boots to dry naturally at room temperature, away from direct heat sources.

Leather Care

Apply leather conditioner every 2-3 months to prevent cracking and maintain water resistance. Use specialised leather cleaners for tough stains. Polish smooth leather boots monthly to protect against moisture damage. Test new products on a small area first to avoid discolouration.

Storage Solutions

Store safety boots in a cool dry place with consistent temperature. Insert cedar shoe trees to absorb moisture and maintain shape. Keep boots away from radiators or direct sunlight. Use boot bags during transport to protect against scratches.

Professional Repairs

Check stitching monthly for signs of wear. Replace worn laces immediately to prevent tripping hazards. Have loose soles repaired by professional cobblers. Replace safety footwear when toe caps become visible or soles wear through.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Basic cleaning | Daily | Prevents dirt build-up |

| Deep cleaning | Weekly | Maintains appearance |

| Leather conditioning | Every 2-3 months | Prevents cracking |

| Professional inspection | Every 6 months | Identifies wear issues |

| Full replacement | 12-18 months | Maintains protection |

Signs of Wear

Monitor these key indicators:

- Visible toe caps through leather

- Smooth or worn tread patterns

- Splits in leather uppers

- Damaged or missing lace eyelets

- Separation between sole and upper

- Compressed or damaged insoles

Seasonal Care

Apply additional waterproofing treatments before wet seasons. Clean salt stains promptly during winter months. Use breathable treatments in summer to prevent excess sweating. Replace insoles seasonally to maintain comfort levels.

Conclusion

We’ve explored the comprehensive world of safety footwear available in Belfast UK. From premium brands to budget-friendly options our guide helps you navigate the essential requirements and standards for workplace foot protection.

Remember that investing in quality safety footwear isn’t just about meeting regulations – it’s about protecting your feet and ensuring comfort throughout long working hours. At Norsemen Safety, we offer expert fitting services and a wide range of options to suit every industry need.

Whether you’re in construction manufacturing or any industrial setting we’re here to help you find the perfect safety boots that meet UK standards and keep you safe on the job.

Frequently Asked Questions

What safety standards should work boots meet ?

Safety footwear in Belfast must comply with EN ISO 20345:2011 standards, which establish protection levels from S1 to S5. All safety boots must meet basic requirements (SB) including toe protection. Additional markings indicate specific protections like slip resistance, puncture protection, and water resistance.

How often should I replace my safety boots?

Generally, safety boots should be replaced every 6-12 months, depending on usage and working conditions. Signs that indicate replacement include worn-out soles, damaged toe caps, torn uppers, or compromised water resistance. Regular inspections help determine when replacement is necessary.

What features should I look for in construction safety boots?

Construction safety boots must have steel toe caps, slip-resistant outsoles, and ankle protection. Look for waterproof materials, puncture-resistant midsoles, and energy-absorbing heels. Ensure the boots meet S3 protection level for optimal safety in construction environments.

Where can I buy safety footwear in Belfast?

Safety footwear is available Norsemen Safety a specialised industrial supplier in Belfast.

Call 028 9046 0541

How should safety boots fit properly?

Safety boots should have about 1cm space between your longest toe and the boot tip. Try boots on in the afternoon when feet are slightly swollen, wear appropriate work socks, and walk around to check for pressure points. Ensure boots are snug but not tight around the heel and ankle.

How do I maintain my safety footwear?

Clean boots regularly with appropriate cleaning products, remove dirt after each use, and allow them to dry naturally away from direct heat. Apply leather conditioner monthly for leather boots, and store them in a cool, dry place. Regular maintenance extends their lifespan and maintains protection levels.

What’s the difference between S3 and S5 rated safety boots?

S3 rated boots are suitable for dry environments and feature leather uppers, while S5 rated boots are designed for wet conditions with rubber or polymeric waterproof uppers. Both offer toe protection, puncture resistance, and antistatic properties, but S5 provides superior water protection.

Can I wear regular work boots instead of safety boots?

No, regular work boots don’t provide the certified protection required by UK workplace safety regulations. Safety boots must meet specific EN ISO standards and include features like toe protection and slip resistance to ensure worker safety in hazardous environments.