Welding Machine Calibrations in Northern Ireland & Ireland – Norsemen Safety

Norsemen Safety provides professional welding machine calibrations across Northern Ireland & Ireland. MIG, TIG & welder calibrations with full service & sales. Call 028 9046 0541

Why Welding Machine Calibrations Matter

In today’s competitive industrial and manufacturing sectors, welding quality and safety are critical. Whether you are a fabrication workshop, construction company, or engineering contractor, the reliability of your welding machines directly impacts product quality, compliance, and operator safety.

That’s why welding machine calibrations are essential. At Norsemen Safety, based in Belfast, we now proudly offer welding machine calibration services across Northern Ireland and Ireland, helping businesses stay compliant, reduce downtime, and maintain welding standards to the highest level.

What Are Welding Machine Calibrations?

Welding machine calibration is the process of checking and adjusting your welding equipment to ensure it delivers the correct voltage, current, and settings in line with international standards.

- Welder calibrations verify that the output displayed on the machine matches the actual output delivered.

- This process is vital for MIG welder calibrations and TIG welder calibrations, where precision is critical to achieving quality welds.

- Calibrations help reduce welding defects, rework, and costly downtime.

Why Welding Machine Calibrations Are Essential

- Compliance with Standards

Many industries require welding equipment to be calibrated regularly to comply with ISO, BS EN, and CE standards. Welding inspections and audits often check calibration certificates.

- Improved Welding Quality

Correct calibration ensures welders achieve the correct penetration, strength, and finish on joints, reducing the risk of failures.

- Operator Confidence

Welders can trust that the settings they input produce the expected results, increasing productivity and reducing frustration.

- Cost Savings

Properly calibrated machines reduce wasted consumables, gas, and rework costs.

Welding Machine Calibrations in Northern Ireland & Ireland

Norsemen Safety is proud to extend our services across Belfast, Northern Ireland, and throughout Ireland. Our calibration engineers travel directly to your site, ensuring minimal disruption to your operations.

We cover a wide range of sectors:

- Manufacturing and fabrication workshops

- Construction and engineering companies

- Shipbuilding and heavy industry

- Agricultural machinery repair

- Automotive and transport engineering

Wherever welding is taking place, our welding machine calibration service ensures compliance, accuracy, and safety. Call 028 9046 0541

Our Welding Machine Calibration Services

At Norsemen Safety, we calibrate a wide range of welding equipment, including:

MIG Welder Calibrations

- Ensuring correct wire feed speed, voltage, and current output.

- Ideal for fabrication, automotive, and general manufacturing sectors.

TIG Welder Calibrations

- Precision calibration for voltage and amperage output.

- Essential for stainless steel, aluminium, and high-specification welding projects.

Multi-Process Welder Calibrations

- For modern machines that combine MIG, TIG, and Stick welding functions.

Welding Equipment Service & Sales

In addition to calibrations, Norsemen Safety offers full welding equipment servicing and sales. If your machine requires repair, replacement, or upgrade, we supply industry-leading brands such as Miller Welding, Stahlwerk, and Optrel.

The Calibration Process: What to Expect

- Initial Inspection – Our engineers check your machine’s condition and safety features.

- Output Testing – Using certified equipment, we measure the actual performance against machine settings.

- Adjustment – Where needed, we adjust the machine to align with required standards.

- Certification – You receive a full calibration certificate for compliance records.

- Service Advice – If we identify issues beyond calibration, we advise on repairs or replacements.

How Often Should You Calibrate Your Welding Machines?Best practice recommends calibrating your welding machines:

- Annually for most businesses.

- More frequently if machines are heavily used, exposed to harsh conditions, or involved in critical welding applications (e.g., aerospace, shipbuilding).

By scheduling regular calibrations with Norsemen Safety, you stay ahead of inspections and ensure consistent weld quality.

Why Choose Norsemen Safety for Welding Machine Calibrations?

- Local Expertise – Serving customers across Northern Ireland and Ireland.

- Certified Engineers – Experienced technicians using certified calibration equipment.

- Comprehensive Service – From welder calibrations to full welding equipment service and sales.

- Trusted Supplier – Authorised distributor for leading welding and safety brands.

- Customer Support – Fast response times and flexible on-site services.

Welding Equipment Service and Sales

Calibration is just one part of maintaining your welding operation. At Norsemen Safety, we also provide:

- New welding equipment sales – MIG, TIG, Stick, and multi-process machines.

- Consumables – Wires, rods, and accessories for ongoing production.

- Welding PPE – Helmets, gloves, respirators, and safety clothing.

- Fume Extraction Solutions – Keeping operators safe from harmful welding fumes.

This full-service approach makes us a one-stop shop for welding equipment service and sales in Northern Ireland and Ireland.

Industries We Support

We work with clients in:

- Construction and civil engineering

- Manufacturing and fabrication

- Aerospace and shipbuilding

- Energy and utilities

- Agriculture and machinery repair

Every sector benefits from accurate welder calibrations to maintain safety and compliance.

Frequently Asked Questions (FAQ)Q: Do you provide calibration certificates?

Yes, after every calibration we issue a traceable calibration certificate for compliance and inspection purposes.

Q: Can you calibrate machines on-site?

Absolutely – our engineers come directly to your premises anywhere in Northern Ireland or Ireland.

Q: What brands of welders can you calibrate?

We calibrate all leading brands, including Miller, Lincoln Electric, ESAB, Fronius, and Stahlwerk.

Q: What happens if my machine fails calibration?

We’ll advise on adjustments, repairs, or replacement options from our welding equipment service and sales department.

Book Your Welding Machine Calibration Today – Call 028 9046 0541

If you need welding machine calibrations, welder calibrations, MIG welder calibrations, or TIG welder calibrations in Northern Ireland or Ireland, Norsemen Safety is your trusted partner.

📞 Call our team today on 028 9045 1055

📧 Email: info@0d04d28e-72a4-47fa-b9bd-42897efedf67.cc12.conves.io

🌍 Visit: www.0d04d28e-72a4-47fa-b9bd-42897efedf67.cc12.conves.io

Ensure your welding equipment meets industry standards, keeps your operators safe, and delivers consistent quality.

Conclusion

Welding machine calibration is not just a compliance requirement – it’s a vital part of ensuring welding quality, safety, and cost efficiency. By partnering with Norsemen Safety, businesses across Northern Ireland and Ireland gain peace of mind knowing their welding equipment is properly calibrated, serviced, and supported.

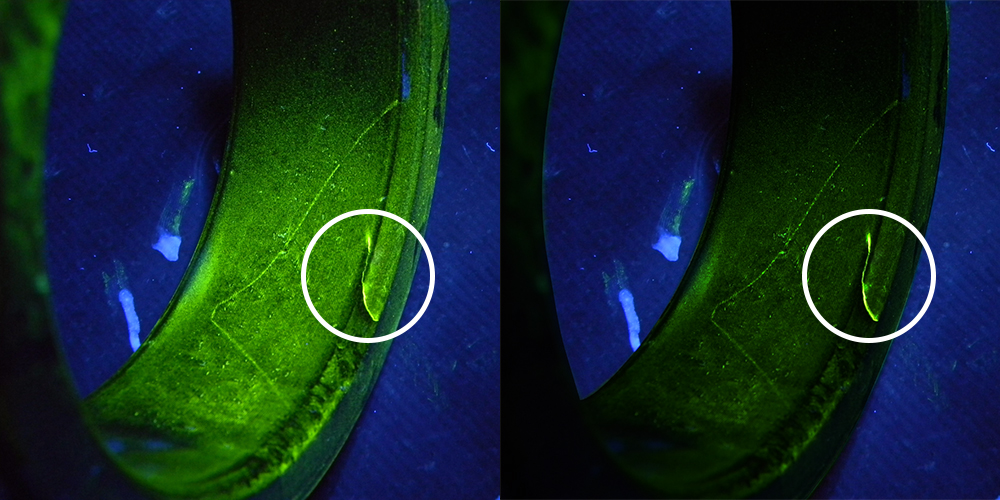

Just a reminder Norsemen Safety/Welder’s Choice are a proud supplier of NDT consumables from Magnaflux.

From welder calibrations to welding equipment service and sales, we are here to support your operation every step of the way.