The Comprehensive Guide to Air Fed Welding Masks

Air Fed Welding Masks

Air Fed Welding Masks are important in the demanding and hazardous world of welding, the health and safety of professionals are paramount. At Welder’s Choice, based in Belfast and serving all of Northern Ireland, Ireland, and the UK, we understand the critical role that high-quality equipment plays in ensuring these protections. Specializing in the supply of air fed welding masks from top brands like Optrel, Miller, Jackson Safety, and Parweld, our goal is to equip you with the best tools for the job. This comprehensive guide delves deep into the benefits, components, and selection criteria of air fed welding masks, adhering to British standards and featuring TM3 welding filters.

Understanding Air Fed Welding Masks

What is an Air Fed Welding Mask?

An air fed welding mask is more than just protective gear; it’s an advanced integration of safety and technology designed for welders. These masks do not merely shield the face and eyes from the physical dangers of welding, such as intense heat and optical radiation but also create a breathable environment by delivering filtered air directly to the wearer. This dual-functionality makes them indispensable in environments where exposure to harmful fumes and particles is high.

Why Air Fed Welding Masks Are Essential

Welding processes can generate a range of hazardous byproducts, including metal fumes, gases, and vapors. Long-term exposure to these substances can lead to significant health issues, such as metal fume fever, lung disease, and even neurological problems. Air fed welding masks offer a high level of protection by filtering these harmful substances out before they can be inhaled, thereby not only preserving the welder’s health but also enhancing focus and productivity by providing a clearer visual and respiratory environment.

Detailed Components of Air Fed Welding Masks

The Mask Itself

The primary component of the air fed welding mask is the mask itself, which is meticulously designed to offer maximum protection and comfort. Constructed from durable, heat-resistant materials, these masks withstand the harsh conditions of welding operations. Features might include anti-fog visors to maintain clear vision and padded linings to ensure comfort even with prolonged use. Adjustable straps allow for a customized fit that secures the mask in place, enhancing its protective capabilities.

The Air Supply Unit

The air supply unit is a pivotal part of the air fed welding system. It typically includes a lightweight, portable blower unit that filters and pumps air into the mask. This unit can be powered by batteries or connected to an external power source, providing continuous clean air flow that prevents the inhalation of dangerous particles. The flow rate can often be adjusted to suit the conditions of the work environment, allowing for flexibility and adaptability.

The Filter System

At the core of the mask’s functionality is the sophisticated filter system, designed to meet stringent safety standards such as those set by British regulations. These multi-layered filters effectively trap particulates, gases, and vapors, ensuring that only clean, safe air is inhaled by the user. The filters are typically replaceable, and some models include indicators for when a filter change is necessary, which is crucial for maintaining the mask’s effectiveness.

Operational Mechanics of Air Fed Welding Masks

The functionality of air fed welding masks centers around creating a positive pressure environment within the mask. This pressure barrier is critical in preventing contaminated air from entering the mask. The air, pushed into the mask by the air supply unit, passes through the advanced filters before reaching the welder, thereby ensuring that every breath drawn is free of contaminants.

Selecting the Right Air Fed Welding Mask

When choosing an air fed welding mask, several factors should be considered to ensure optimal protection and functionality:

- Protection Level: Ensure the mask meets all relevant safety standards and is capable of filtering the specific contaminants encountered in your welding environment.

- Comfort and Fit: A good mask should be comfortable to wear for extended periods, with adjustable straps and adequate cushioning.

- Durability and Quality: Opt for masks constructed with high-quality materials capable of withstanding the rigors of welding tasks. Brands like Optrel, Miller, Jackson Safety, and Parweld are renowned for their robust construction and reliability.

- Maintenance and Usability: Consider how easy it is to maintain and operate the mask. Features like easy-to-change filters and clear maintenance indicators can save time and ensure the mask is always ready for use.

- Brand Reputation and Support: Choosing a mask from a reputable brand can ensure access to customer support and spare parts. It’s also beneficial to consider warranties and service options available with the purchase.

Maintenance and Care

To maximize the lifespan and effectiveness of an air fed welding mask, regular maintenance is essential. This includes routine cleaning of the mask and replacement of the filters as per the manufacturer’s guidelines. Proper storage is also crucial; the mask should be stored in a cool, dry place away from direct sunlight to prevent material degradation.

Brand Comparisons

When selecting an air fed welding mask, the brand can significantly influence the quality, comfort, and durability of the product. Here, we spotlight some of the industry leaders whose products we proudly offer at Welder’s Choice.

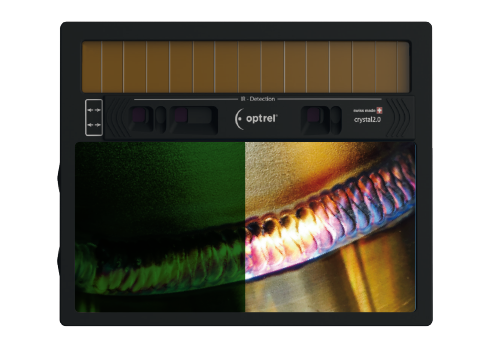

Optrel

Swiss-made Optrel welding masks are renowned for their innovation and quality. The Optrel e684, for instance, is highly acclaimed for its auto-darkening filter which adjusts to varying light conditions, providing optimal visibility without manual adjustments. Its respiratory protection system, integrated into the helmet, meets TH3 protection class standards, offering one of the highest levels of respiratory safety available.

Miller

Miller Electric is a stalwart in the welding equipment market, known for robust engineering and reliable performance. Their masks often feature the ClearLight Lens Technology, which allows for a very clear view in both light and dark states, enhancing visibility and reducing eye strain. Miller’s masks are designed with ergonomics in mind, offering lightweight options that reduce neck strain and fatigue.

Jackson Safety

Jackson Safety offers welding helmets that are great for professional welders who prioritize safety and budget. Their models often include aerodynamic shells designed to reduce fume buildup, with ample space to accommodate respirators comfortably. Jackson Safety helmets are praised for their balance, fit, and extended coverage.

Parweld

UK-based Parweld has been producing welding equipment for over 50 years. Their XR940A PAPR (Powered Air Purifying Respirator) Air Fed Welding System exemplifies their commitment to safety and user comfort. It provides constant, clean, and cool air, has a lithium-ion battery with an 8-hour life, and includes a large viewing area that enhances the welder’s field of vision during complex tasks.

British Safety Standards and Certifications

British and European safety standards are rigorous, ensuring that all air fed welding masks provide adequate protection against the specific hazards of welding. Understanding these standards can help welders make informed choices about their safety gear.

EN12941

This standard tests the TH (Total Inward Leakage) levels of powered air respirators. Masks meeting this standard, like those from Optrel and Parweld, provide a TH2 or TH3 level of protection, with TH3 being the highest standard, indicating the least amount of inward leakage.

EN175

This standard applies to all welding helmets and hand shields, ensuring they provide adequate protection against both radiation and mechanical risks in welding environments. It covers everything from optical quality to robustness, ensuring that the mask can withstand high-temperature sparks and spatter.

EN379

This standard focuses on the auto-darkening feature found in welding helmets. It assesses the optical quality of the filter, the range of shade levels, and its reaction time. Brands like Miller that feature advanced auto-darkening technologies ensure rapid response times to changes in light, protecting the welder’s eyes from sudden arcs.

Choosing Based on Standards

When selecting an air fed welding mask, consider which standards are most relevant to your work environment. For those frequently exposed to high levels of fumes and vapors, a TH3-certified helmet might be essential. Meanwhile, for work involving varied lighting conditions, a helmet that meets EN379 could offer better protection and comfort.

Conclusion

The selection of an air fed welding mask should be informed by a detailed understanding of both the product’s features and the safety standards they meet. At Welder’s Choice, we are dedicated to offering only the best in the market, certified to meet or exceed British and European safety standards. Whether you are a professional welder in Northern Ireland, Ireland, or the UK, trust us to provide you with equipment that ensures your safety, enhances your comfort, and helps you perform at your best.

Learn more about welding fume and how to protect yourself by click here on the HSENI website.