Fixed Gas Detectors and Portable Gas Detectors: Key Insights for Workplace Safety

Gas detection is a critical aspect of safety in various industries, ensuring the protection of workers from potentially harmful gases. This article explores the importance of gas detection, the differences between fixed and portable gas detectors, the types of gases detected, and the applications of these devices. We will also discuss installation considerations, factors to consider when purchasing gas detectors, common sensor types, maintenance requirements, training and education, and future trends in gas detection technology. Stay tuned to learn everything you need to know about fixed and portable gas detection.

Introduction to Fixed and Portable Gas Detection

Introduction to Fixed and Portable Gas Detection provides an overview of the essential tools and technologies used in monitoring hazardous gases in various environments, ensuring safety and compliance.

Gas detectors play a critical role in safeguarding lives and property by constantly monitoring the presence of harmful gases in industrial, commercial, and residential settings. Portable gas detectors, designed for on-the-go use, offer flexibility and mobility in detecting toxic gases while fixed gas detection systems provide continuous monitoring for long-term protection. These devices are equipped with advanced sensors and alarms that trigger alerts when gas levels exceed safe limits, allowing for prompt intervention and prevention of potential disasters.

Importance of Gas Detection

Understanding the importance of gas detection is crucial for maintaining safety in industries dealing with hazardous gases, ensuring compliance with regulations and standards whilst enabling continuous monitoring.

Gas detection plays a vital role in safeguarding the well-being of workers, preventing potential accidents, and minimising the risk of catastrophic events. The implementation of advanced monitoring systems allows for real-time data collection, analysis, and response, enhancing overall safety measures within industrial settings. Along with protecting personnel, efficient gas detection also helps in safeguarding equipment, infrastructure, and the environment from the dangers associated with gas leaks or exposure. Compliance with industry-specific protocols and legal requirements is essential for maintaining operational integrity and fostering a culture of safety consciousness.

Fixed Gas Detectors

Fixed Gas Sensors are fixed devices designed to monitor gas concentrations in specific areas, providing continuous monitoring to ensure safety and early detection of hazardous levels.

These sensors play a crucial role in industrial, commercial, and residential settings, where the release of hazardous gases could pose significant risks. By continuously measuring the levels of gases such as carbon monoxide, hydrogen sulphide, methane, and more, these devices can alert individuals to potential dangers promptly. The real-time data provided by fixed gas sensors allows for quick response measures to be implemented, preventing accidents and protecting both life and property.

Overview of Fixed Gas Detectors

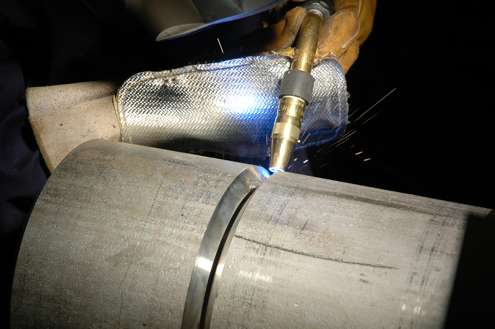

An overview of Fixed Gas Detectors includes their installation in fixed systems, strategic placement in critical areas, and their role in safeguarding employees and companies against potential gas hazards.

These detectors are designed to continuously monitor the presence of hazardous gases in industrial environments, such as manufacturing plants, refineries, and storage facilities.

- By detecting leaks or abnormal levels of gases like methane, carbon monoxide, or hydrogen sulphide, Fixed Gas Detectors provide early warning to employees and allow for prompt response to prevent accidents and injuries.

- Their integration with alarm systems can trigger automatic shutdown procedures, ventilation systems, or emergency notifications, enhancing the overall safety protocols within a facility.

Advantages of Fixed Gas Detectors

MSA Fixed Gas Detectors offer advantages such as continuous monitoring, immediate alerts, and alarm notifications that comply with industry requirements, ensuring timely responses to gas leaks and safety hazards.

These detectors are crucial for maintaining a safe working environment by continuously measuring the presence of harmful gases such as carbon monoxide, hydrogen sulphide, and methane.

They boast advanced alert systems that can notify designated personnel in real-time when gas levels exceed safe limits, allowing for rapid evacuation or containment measures.

Fixed gas detectors align with industry standards such as HSE and EA regulations, ensuring compliance and adherence to safety protocols within various sectors, including manufacturing, petrochemical, and pharmaceutical industries.

Portable Gas Detectors

Portable Gas Detectors are mobile devices used to alert workers of potential gas hazards in various environments, enhancing safety measures and providing immediate warnings in critical situations.

This innovative technology is designed to detect a wide range of gases, from carbon monoxide to hydrogen sulphide, ensuring a quick response to any danger. Due to their compact size and lightweight construction, portable gas detectors are easy to carry around, making them ideal for workers in industries like oil and gas, construction, and chemical plants. These devices play a crucial role in preventing accidents by continuously monitoring gas levels and triggering alarms when thresholds are exceeded.

Overview of Portable Gas Detectors

The overview of Portable Gas Detectors includes their ability to monitor gas levels, provide warnings, and meet industry requirements, ensuring companies adhere to safety regulations and protect their workforce.

One key feature of portable gas detectors is their advanced warning systems that emit audible alarms and visual indicators when gas levels exceed specified thresholds, alerting users to potential hazards in their environment.

Along with this, many models are equipped with internal sensors that continuously monitor gas concentrations, allowing for real-time updates on air quality.

These detectors also come with customisable settings for alarm thresholds, providing flexibility to suit varied work environments.

Portable gas detectors are designed to be compliant with stringent industry standards ensuring accuracy and reliability in gas detection.

Advantages of Portable Gas Detectors

Portable Gas Detectors offer advantages in diverse applications, alerting workers to gas hazards, and monitoring gas levels effectively, enhancing safety in various work environments.

These compact devices are essential tools for industries such as oil and gas, chemical plants, mining, and confined spaces. By providing real-time alerts to dangers like carbon monoxide, hydrogen sulphide, and flammable gases, they enable quick responses to mitigate risks.

Portable gas detectors precisely monitor gas levels ensures that safety protocols are followed, preventing accidents and maintaining compliance with regulations. Portable gas detectors play a crucial role in safeguarding workers’ health and well-being, offering peace of mind in hazardous work settings.

Fixed vs. Portable Gas Detectors

Comparing Fixed and Portable Gas Detectors involves evaluating their performance in different work environments, ability to provide immediate warnings, effectiveness in safety precautions, and adaptability to changing conditions.

Fixed gas detectors are typically installed in a fixed position within industrial facilities or buildings to continuously monitor for the presence of hazardous gases. These detectors are crucial for early detection of gas leaks and triggering alarms to prompt immediate evacuation or safety measures.

On the other hand, portable gas detectors offer flexibility by allowing personnel to carry them around, making them ideal for tasks that involve moving between different areas with potential gas exposure.

Types of Gases Detected

Gas detectors can identify various types of gases, including specific ones with unpredictable levels that pose risks in high-risk zones, storage tanks, and other critical environments.

These detectors play a vital role in ensuring safety by monitoring the presence of flammable gases like methane or propane that can lead to explosions if leaked in confined spaces. Along with flammable gases, toxic gases such as hydrogen sulphide or carbon monoxide are also commonly detected.

The continuous tracking of these gases helps in preventing health hazards and maintaining compliance with safety regulations. The ability of gas detectors to detect a wide range of gases makes them essential tools in industrial settings.

Applications of Gas Detectors

Gas detectors find applications in various industrial locations, providing comprehensive coverage in infrastructure sites, ensuring public safety, and safeguarding critical environments from potential gas hazards.

These sophisticated devices are essential tools in industrial settings, where they play a crucial role in detecting hazardous gases like carbon monoxide, methane, and hydrogen sulphide. Gas detectors are designed to alert workers of any dangerous gas levels, preventing potential accidents and ensuring a safe working environment. In infrastructure sites such as oil refineries, chemical plants, and manufacturing facilities, these detectors are vital for monitoring gas leaks, early detection of fires, and maintaining air quality standards. The importance of public safety is highlighted by the use of gas detectors in public spaces such as schools, hospitals, and shopping centres, where the well-being of individuals is a top priority.

Installation Considerations for Gas Detectors

Proper installation considerations for gas detectors include incorporating preventive maintenance practices, strategic placement in common areas, adherence to compliance measures, and alignment with industry standards for effective monitoring. MSA Safety are the leaders in fixed gas detection, Norsemen Safety is a proud MSA Safety distributor supplying MSA gas monitors both fixed and portable to industry in Ireland and the UK. Get in touch to discuss your gas detection requirements.

Preventive maintenance plays a crucial role in ensuring the longevity and accuracy of gas detectors. Regular inspections, calibration checks, and sensor replacements are essential tasks to uphold their functionality.

Strategic placement in common areas like kitchens, boiler rooms, and industrial facilities is vital to detect potential gas leaks promptly. Ensuring detectors are installed at optimal heights and distances from potential sources of gas is paramount for early detection.

Compliance requirements set the guidelines for the types of detectors, installation protocols, and maintenance schedules that need to be followed. Adhering strictly to these regulations is necessary to mitigate risks and ensure a safe environment.

Industry standards such as HSE and FPA provide specific guidelines on the installation and maintenance of gas detectors. Following these standards not only ensures regulatory compliance but also enhances overall safety measures in the facility.

Common Sensor Types in Gas Detectors

Gas detectors utilise common sensor types such as electrochemical sensors, LED panels for display, measurement units like parts per million (PPM), and compliance thresholds like Permissible Exposure Limits (PEL).

Electrochemical sensors are often used in gas detectors for their high sensitivity to specific gases such as carbon monoxide or hydrogen sulphide, providing accurate and reliable detection capabilities. LED panel displays offer clear visual indications of gas levels and alarms, ensuring easy monitoring for operators.

The measurement units in gas detectors, represented as parts per million (PPM), help in quantifying gas concentrations in the air, giving a numerical value that indicates potential hazards. Compliance standards such as Permissible Exposure Limits (PEL) set by regulatory bodies ensure that workplaces maintain safe levels of gas exposure, protecting the health and safety of individuals.

Gas Detector Maintenance

Maintaining gas detectors is crucial for ensuring safety monitoring, comprehensive coverage, and early detection of gas hazards, highlighting the importance of regular maintenance in preserving the effectiveness of these devices.

Gas detector maintenance plays a pivotal role in upholding workplace safety standards and minimising the risks associated with gas leaks. Regular upkeep ensures that these devices function optimally, providing a reliable shield against potential dangers.

Consistent monitoring of gas detector performance enables swift identification of any malfunctions or deviations, preventing any lapses in safety protocols.

Proper maintenance routines extend the lifespan of gas detectors, offering long-term cost savings and uninterrupted protection. With comprehensive coverage achieved through regular checks and calibrations, organizations can create a secure environment conducive to employee well-being and operational efficiency.

Importance of Regular Maintenance

Regular maintenance of gas detectors is essential to uphold environmental safety standards, meet industry applications, ensure continuous monitoring, and facilitate effective emergency response protocols.

Gas detectors play a critical role in various sectors, including manufacturing, petrochemical, mining, and more. Proper maintenance not only ensures their accuracy and reliability but also helps in identifying and preventing potential hazards that could lead to environmental disasters or health risks to personnel.

Continuous monitoring provided by well-maintained detectors is vital in detecting leaks or abnormal gas levels promptly, thus preventing accidents and ensuring a safe working environment. Regular maintenance enhances the readiness of emergency response teams by ensuring the detectors are fully functional during critical situations.

Training and Education on Gas Detection

Training and education on gas detection are vital for ensuring adherence to industry standards, implementing safety precautions, understanding electric codes, and receiving expert guidance on effective gas detection practices.

Recognising the importance of comprehensive training in gas detection, professionals learn to identify potential hazards, interpret sensor readings, calibrate equipment accurately, and troubleshoot common issues.

Staying updated on the latest technological advancements and regulatory requirements guarantees that individuals can handle diverse gas detection scenarios with proficiency and confidence.

Future Trends in Gas Detection Technology

Future trends in gas detection technology focus on expanded coverage capabilities, emphasis on preventative maintenance strategies, adoption of standard protocols, and integration of advanced technologies for enhanced detection and safety measures.

One of the key areas receiving substantial attention is the enhancement of sensor capabilities to detect a wider range of gases, enabling early detection of potential hazards. The shift towards cloud-based monitoring systems is gaining momentum, allowing real-time data analysis and remote access for efficient management. The implementation of predictive maintenance algorithms is also becoming prevalent, ensuring optimal performance and minimising downtime. The industry is witnessing a growing inclination towards the incorporation of AI and machine learning algorithms to improve accuracy and reliability in gas detection processes.

Future Trends in Gas Detection Technology

Looking ahead, the future trends in gas detection technology will focus on providing flexible protection solutions, adapting to changing conditions, addressing risks in high-risk zones, and ensuring safety in storage tank environments.

Gas detection systems are moving towards more intelligent designs that can quickly adapt to various hazardous scenarios. These systems are being equipped with advanced sensors capable of detecting a wide range of gases, from common pollutants to highly toxic substances, with enhanced precision and speed. The integration of Internet of Things (IoT) technology allows for real-time monitoring and data analysis, which aids in proactively managing potential risks.

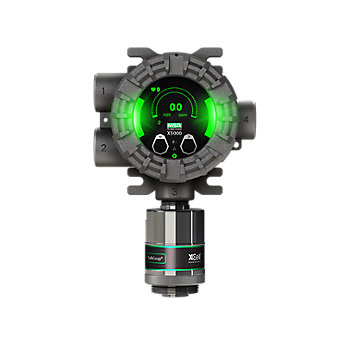

MSA Safety is now the leader in fully integrated cellular connectivity right out-of-the-box, the ALTAIR io 4 delivers real-time visibility to help drive safety and productivity across workers, worksites, and workflows.

ALTAIR io 4 features:

- Designed with fully integrated connectivity for real-time visibility across your worksites from Day One

- CAT-M LTE cellular connectivity and integration with the MSA Grid

- Deploys in seconds, right out of the box. No IT required

- Rugged, durable design and Industry-Leading XCell® Sensors

- Survives a 25-foot drop test. Breakthrough sensor design enables faster response and shorter span calibrations

- 1 to 4 gas options available. Sensor Options: Combustible (LEL), Oxygen, Carbon Monoxide, Hydrogen Sulfide, Methane, H2S Low-Concentration, CO – Hydrogen Resistant

The ALTAIR io 4 is part of the MSA Connected Work Platform, which helps to simplify safety, curb risk, and boost productivity.

In storage tank facilities, there is a growing emphasis on implementing predictive maintenance strategies to prevent equipment failures and reduce the likelihood of incidents. By leveraging cutting-edge technologies like artificial intelligence and machine learning, modern gas detection solutions are becoming more sophisticated and efficient in safeguarding industrial installations.

Frequently Asked Questions

What is the difference between fixed gas detection and portable gas detection?

Fixed gas detection refers to stationary gas detection systems that are permanently installed in a specific location, while portable gas detection devices are handheld and can be carried to different areas for on-the-go gas monitoring.

Why do I need both fixed and portable gas detection?

Fixed gas detection systems provide continuous monitoring and can cover larger areas, while portable gas detectors allow for personal monitoring and can be used in areas where fixed systems are not available or practical.

What types of gases can be detected by fixed and portable gas detection systems?

Both fixed and portable gas detectors can detect a wide range of gases including toxic gases, combustible gases, and oxygen levels. Some models may be designed to detect specific gases or a combination of gases.

How do fixed and portable gas detection systems work?

Fixed gas detectors use sensors and alarms to detect and warn of the presence of hazardous gases. Portable gas detectors work similarly, but with a smaller form factor and often with audible and visual alerts.

Are there any maintenance requirements for fixed and portable gas detection systems?

Yes, both types of gas detectors will require regular maintenance to ensure proper functioning. Fixed systems may need to be calibrated and tested periodically, while portable devices may need to have their sensors replaced or recalibrated.