Need help? Call us: 028 9046 0541 or info@0d04d28e-72a4-47fa-b9bd-42897efedf67.cc12.conves.io

Magnaflux NDT Products – For weld inspectors, fabricators, and quality assurance engineers across Northern Ireland, the Republic of Ireland, and the UK, choosing the right non-destructive testing (NDT) products is critical. Whether it’s verifying the integrity of a weld or ensuring the safety of aerospace components, inspections must be precise, reliable, and compliant with strict standards.

When it comes to NDT consumables, one brand leads the way worldwide: Magnaflux. With a history stretching back more than 90 years, Magnaflux is trusted across industries for its magnetic particle inspection (MPI) and dye penetrant inspection (DPI) products.

This guide will walk you through:

By the end, you’ll understand why Magnaflux remains the global standard in non-destructive testing — and how to order the right products for your inspections.

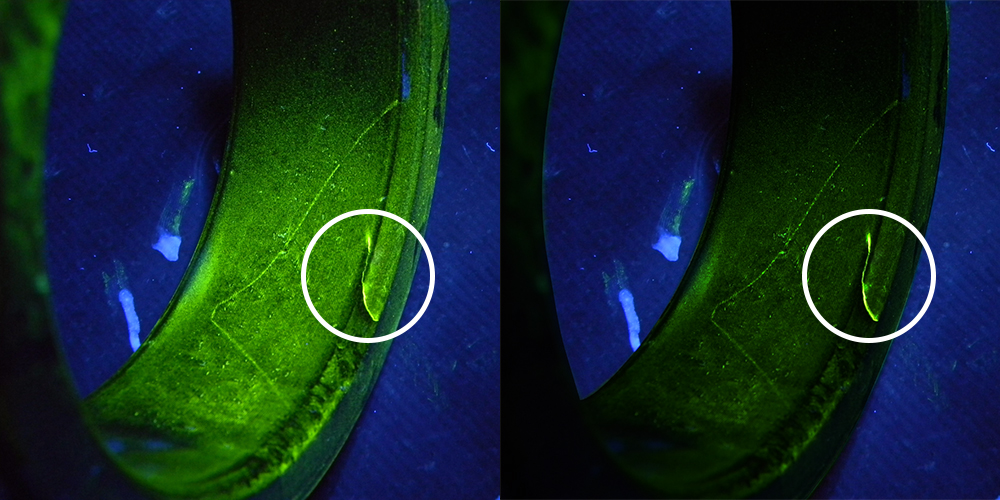

Non-destructive testing (NDT) is the process of evaluating materials, welds, and components for hidden defects without causing damage. It’s essential for safety-critical industries, where even a hairline crack could lead to catastrophic failure.

Magnaflux manufactures specialist MPI and DPI consumables that reveal surface and near-surface flaws. These products are engineered for accuracy, repeatability, and compliance with EN ISO, ASTM, ASME, and NADCAP standards.

Key Benefits of Magnaflux in NDT:

In short, Magnaflux gives inspectors the confidence that every weld, component, or casting meets the required standard of safety and reliability.

Both methods are non-destructive and deliver fast, repeatable results — one of the key reasons Magnaflux non-destructive testing consumables are trusted globally.

Browse our range of Magnaflux non-destructive testing products here.

Aerospace: Checking landing gear, turbines, and precision components.

Automotive: Ensuring engine parts and suspensions meet strict safety standards.

Energy/Oil & Gas: Inspecting welds in pipelines and refineries.

Shipbuilding: Detecting flaws in hulls and heavy fabrications.

Manufacturing & Construction: Routine weld testing for structural steelwork.

Every industry benefits from the accuracy, compliance, and reliability of Magnaflux consumables.

| Material | Recommended Test | Why? |

|---|---|---|

| Ferromagnetic (steel, iron) | Magnetic Particle Inspection (MPI) | Detects surface and near-surface flaws quickly |

| Non-ferrous alloys (aluminium, titanium) | Dye Penetrant Inspection (DPI) | Sensitive for cracks, porosity, and fine surface defects |

| Aerospace-grade alloys | Fluorescent DPI | Highest sensitivity, NADCAP-approved |

| Heavy fabrication (shipbuilding, energy) | MPI | Reliable for large welds and castings |

Still unsure? Contact Norsemen Safety for expert advice on choosing the right Magnaflux NDT products for your application.

When you order through Norsemen Safety, you’re not just buying a can of penetrant spray — you’re partnering with a distributor who understands the whole safety and inspection process.

Q: What is Magnaflux used for in welding?

A: Magnaflux consumables detect cracks, porosity, and discontinuities in welds without damaging the joint.

Q: Can Magnaflux be used in aerospace inspections?

A: Yes — Magnaflux penetrants and powders are certified for aerospace and defence inspections under NADCAP.

Q: Do Magnaflux products meet EN ISO standards?

A: Yes — Magnaflux consumables comply with EN ISO 9934 (MPI) and EN ISO 3452 (DPI).

Q: Where can I buy Magnaflux in Northern Ireland or the UK?

A: Directly from Norsemen Safety – trusted Magnaflux distributor.

The complete guide to Magnaflux NDT products shows why industries worldwide rely on this brand for non-destructive testing. Whether you’re carrying out magnetic particle inspection on steel welds or using dye penetrant consumables on aerospace alloys, Magnaflux provides the accuracy and compliance you need.

Order your Magnaflux NDT products from Norsemen Safety today for fast delivery across Northern Ireland, the Republic of Ireland, and the UK.