Weld Cleaning Machine -Stahlwerk Weld Seam Cleaning SRG-750 Pro Pickling Machine – DISCONTINUED

Orders OVER £60 (Excluding VAT)

Orders UNDER £60 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Weld Cleaning Machine -Stahlwerk Weld Seam Cleaning SRG-750 Pro Pickling Machine – DISCONTINUED

£229.99 (ex VAT) £275.99(inc VAT)

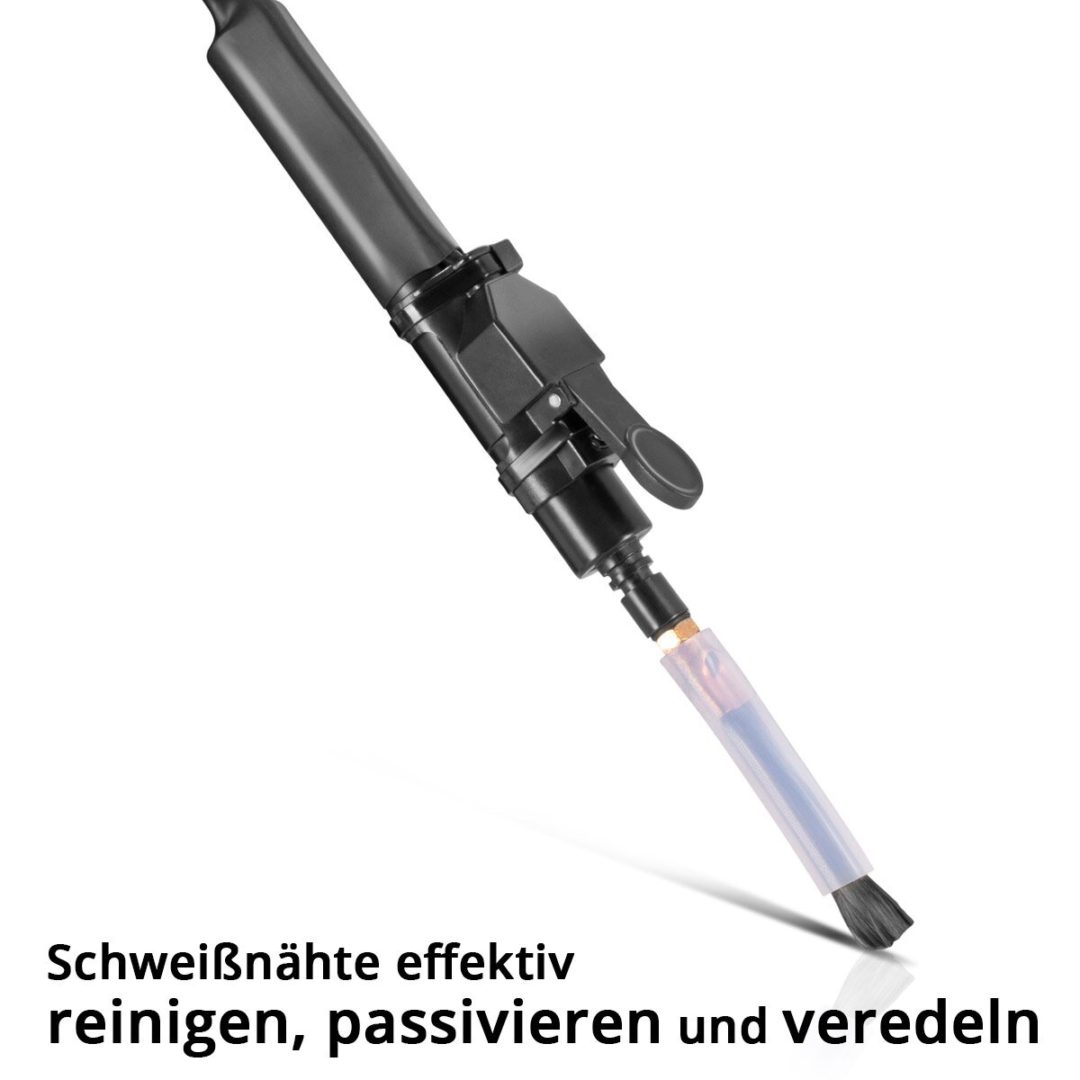

Weld cleaning machine from STAHLWERK, that effectively cleans weld seams , passivated and refined. The high-quality pickling device has an integrated tank for electrolyte cleaner with a capacity of 750 ml and an electric pump for direct application of the liquid.

Out of stock

Orders OVER £60 (Excluding VAT)

Orders UNDER £60 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Have a Question? Ask a Specialist

Low Prices

Price match guarantee

Wide range of products available

Always the correct part

In-House Experts.

We know our products

Easy Returns.

Quick & Hassle Free

Weld Cleaning Machine -Stahlwerk Weld Seam Cleaning SRG-750 Pro Pickling Machine

THIS PRODUCT HAS BEEN DISCONTINUED

This has been discontinued and replaced by the SRG-300 Click here to view it

A light and compact weld cleaning machine from STAHLWERK, that effectively cleans weld seams , passivated and refined. The high-quality pickling device has an integrated tank for electrolyte cleaner with a capacity of 750 ml and an electric pump for direct application of the liquid. The electrolyte cleaner is fed directly into the carbon brush via a hose and the required flow rate can be continuously regulated.

Electrolytic cleaning of weld seams has the advantage that the weld seam is corrosion-resistant after treatment and is not damaged compared to cleaning with a grinder. Cleaning weld seams using the electrolysis process is environmentally and user-friendly because, unlike cleaning with pickling, no substances such as saltpeter, hydrofluoric or sulfuric acid are released. Electrolytically refined weld seams are particularly used in tank and boiler construction or in the food industry. The pickling and passivation device is ideal for professional use in industry, crafts and DIY.

Features

- With the light and compact STAHLWERK weld seam cleaning device, weld seams can be effectively cleaned, passivated and refined.

- The high-quality pickling device has an integrated tank for electrolyte cleaner with a capacity of 750 ml and an electric pump for direct application of the liquid. – The electrolyte cleaner is fed directly into the carbon brush via a hose and the required flow rate can be continuously regulated.

- Electrolytic cleaning of weld seams has the advantage that the weld seam is corrosion-resistant after treatment and is not damaged compared to cleaning with a grinder.

- Cleaning weld seams using the electrolysis process is environmentally and user-friendly because, unlike cleaning with pickling, no substances such as saltpeter, hydrofluoric or sulfuric acid are released. Electrolytically refined weld seams are particularly used in tank and boiler construction or in the food industry. Weld cleaning machine perfect for stainless weld seam cleaning.

This Weld Cleaning Machine Comes With the Following;

- 1 x STAHLWERK weld seam cleaning device SRG-750 Pro

- 1 x Ground Clamp

- 1 x Carbon Fiber Brush

- 1 x Replacement Brush

- 1 x transport case

- 1 x Electrolyte Cleaner 250ml

Electrochemical Cleaning: A Superior Alternative to Abrasive Grinding Technology

Enhance your stainless steel welding projects with an efficient weld cleaning machine, featuring the innovative electrochemical cleaning method. This advanced technology stands as a superior alternative to abrasive grinding.

Stainless steel welding often results in oxidation, visible as discoloration or tarnishing, which necessitates removal for maintaining the metal’s integrity. Oxidation not only detracts from the appearance but also paves the way for corrosion, compromising the metal’s surface. Removing this tarnish effectively eliminates the oxidation layer, thereby reinstating the metal’s corrosion resistance.

Traditionally, weld seams are cleaned using pickling paste, known for restoring the protective oxide layer. However, pickling pastes have their drawbacks, including the formation of unsightly residues and high toxicity, demanding careful handling and disposal. Moreover, abrasive tools like brushes and sponges can mar the delicate surfaces of stainless steel with scratches. In contrast, the Stahlwerk weld cleaning machine using electrochemical cleaning offers a safe, efficient, and aesthetically pleasing solution, preserving the metal’s surface quality while ensuring environmental safety and user-friendliness.

Stahlwerk offers high quality reliable equipment, see some of the other Stahlwerk products we stock.

Weld Cleaning Machine from Stahlwerk SRG-750 – electrochemical weld cleaning machine

THIS PRODUCT HAS BEEN DISCONTINUED

The high-quality pickling device has an integrated tank for electrolyte cleaner with a capacity of 750 ml and an electric pump for direct application of the liquid. – The electrolyte cleaner is fed directly into the carbon brush via a hose and the required flow rate can be continuously regulated.

Electrolytic cleaning of weld seams has the advantage that the weld seam is corrosion-resistant after treatment and is not damaged compared to cleaning with a grinder.

Cleaning weld seams using the electrolysis process is environmentally and user-friendly because, unlike cleaning with pickling, no substances such as saltpeter, hydrofluoric or sulfuric acid are released. Electrolytically refined weld seams are particularly used in tank and boiler construction or in the food industry.