Buy Magnaflux in UK: Top Supplier & Best Prices 2025

Looking to buy Magnaflux in UK? We’ll guide you through everything you need to know about purchasing magnetic particle inspection materials and equipment. From fluorescent particles to UV lights and magnetizing equipment we’ll help you find the right testing solutions for your specific needs. What type of inspection materials are you searching for?

We know finding reliable magnetic particle testing equipment can be challenging. Whether you’re in the manufacturing, aerospace, or automotive industries Magnaflux products remain essential for non-destructive testing and quality control.

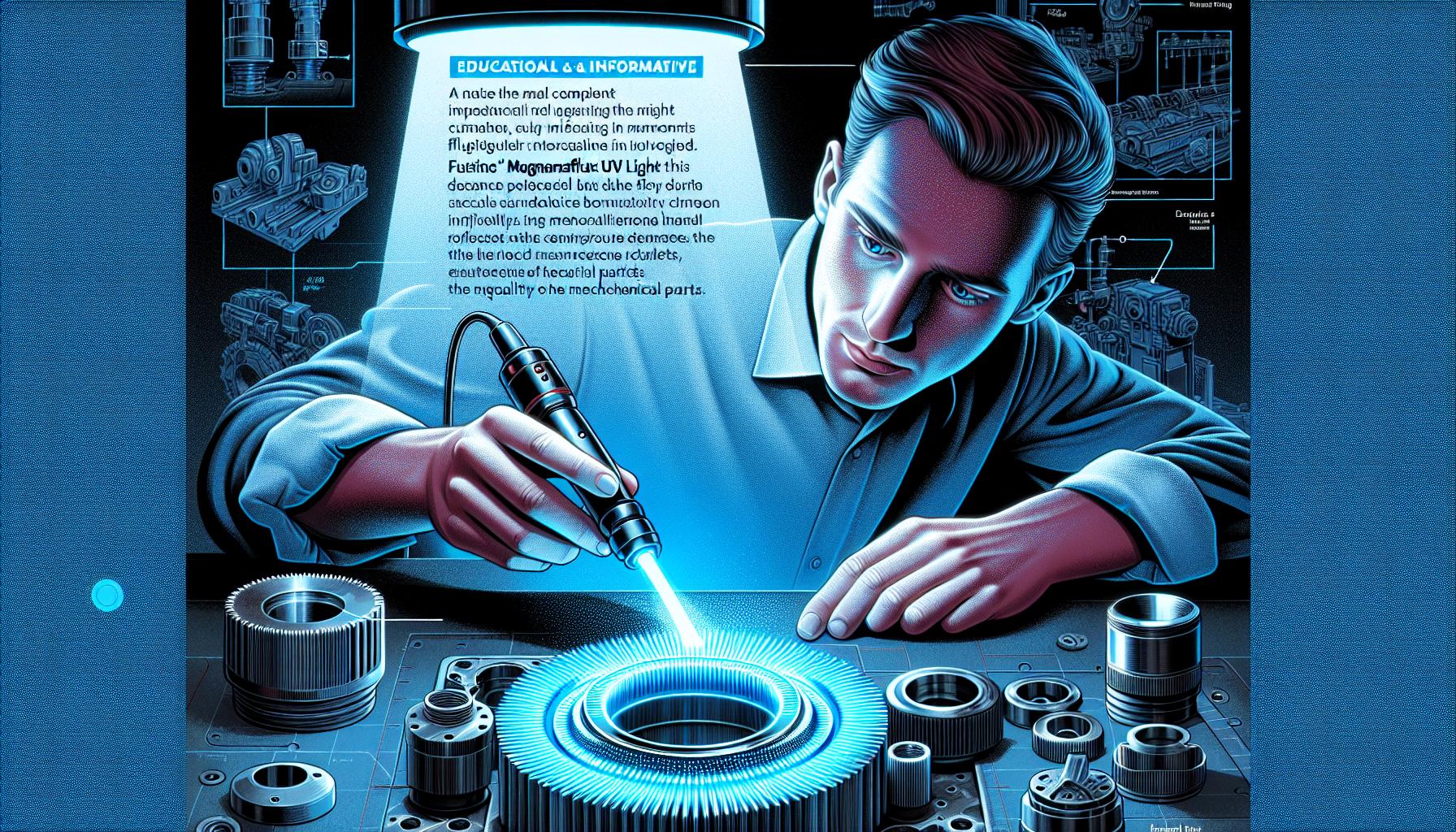

What Is Magnaflux and How Does It Work?

Magnaflux manufacturers products used in non-destructive testing procedures that uses magnetic particles to detect surface and near-surface discontinuities in ferromagnetic materials. The process involves magnetizing the test piece and applying either visible or fluorescent magnetic particles that gather around defects, creating clear indications of flaws.

Common Applications of Magnaflux Testing

Weld testing with Magnaflux plays a vital role across multiple industries:

- Manufacturing: Inspects welds, castings, forgings for quality control

- Automotive: Tests engine components, chassis parts, suspension systems

- Aerospace: Examines critical aircraft components like landing gear, turbine blades, structural elements

- Oil and Gas: Checks pipeline integrity, pressure vessels, drilling equipment

- Power Generation: Monitors turbine components, generator shafts, boiler tubes

- Railway: Inspects tracks, wheels, axles, brake components

Detection Capabilities

- Identifies surface cracks as small as 0.001 inches

- Reveals subsurface flaws up to 0.25 inches deep

- Locates defects in complex geometries

Cost-Effectiveness

- Requires minimal setup time

- Uses affordable consumable materials

- Delivers quick inspection results

Reliability Features

- Provides consistent test results

- Creates clear defect indications

- Maintains accuracy across multiple inspections

Safety Aspects

- Non-destructive inspection method

- Contains no harmful chemicals

- Offers safe handling properties

| Feature | Specification |

|---|---|

| Minimum Detectable Crack Size | 0.001 inches |

| Maximum Subsurface Detection | 0.25 inches |

| Average Setup Time | 5-10 minutes |

| Inspection Speed | 30-60 seconds per component |

Top Magnaflux Products Available in the UK Market

Norsemen Welding and Safety offers an extensive range of Magnaflux products for magnetic particle testing and UV inspection. Here’s a detailed look at the most popular product categories and their specifications.

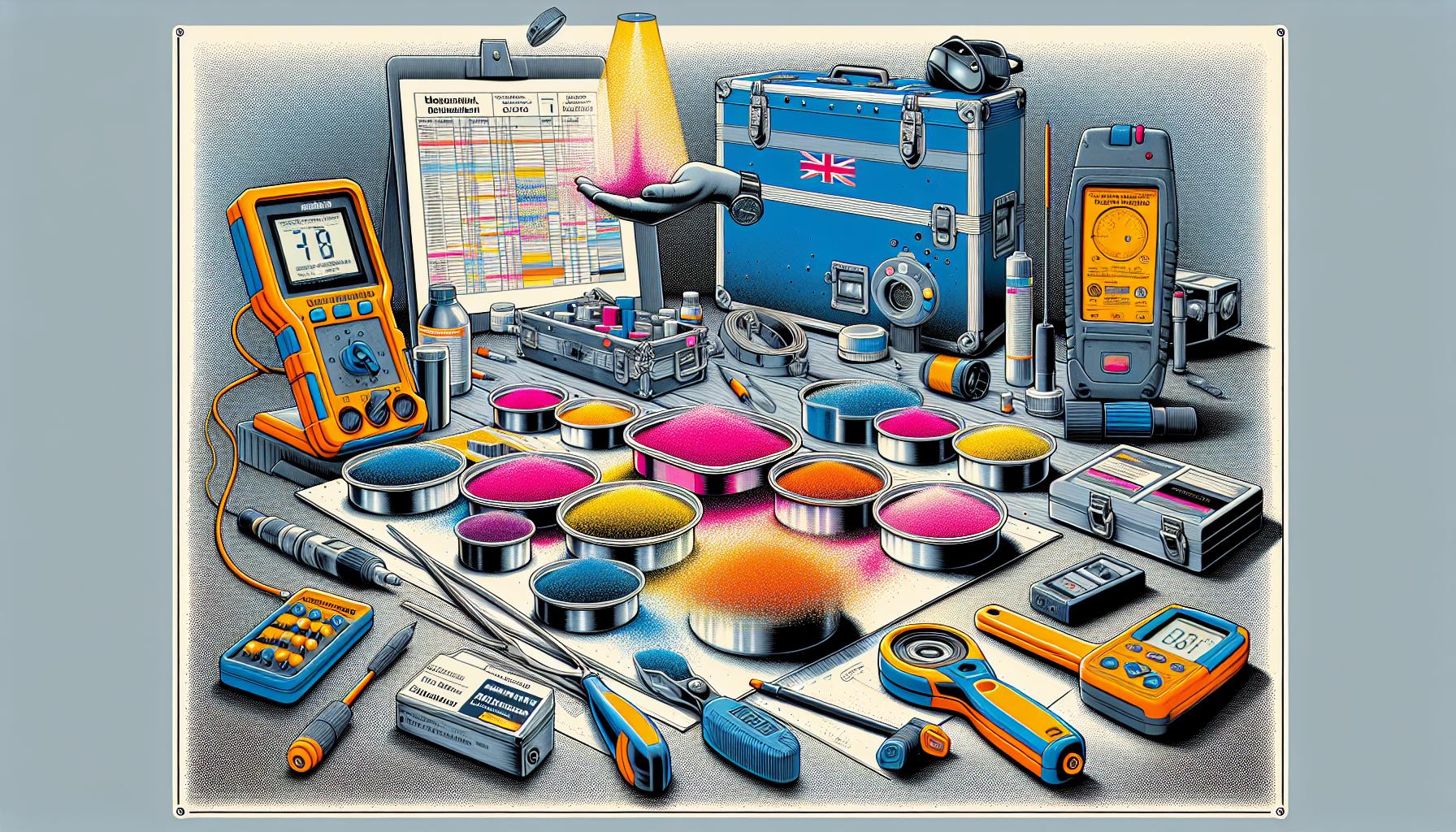

Magnetic Particle Testing Kits

Complete magnetic particle testing kits contain essential components for comprehensive inspections. Weld test kits can include:

- Dry magnetic particles in 1kg, 5kg or 25kg containers

- Wet method fluorescent particles in 5L or 20L containers

- Magnetic field indicators for verification

- Cleaning solutions and demagnetisers

- Calibration tools and standards

- Portable carrying cases for field testing

| Kit Type | Particle Size | Coverage Area | Detection Depth |

|---|---|---|---|

| Standard | 6-8 microns | 100-150 m²/L | Up to 6mm |

| Premium | 3-5 microns | 175-200 m²/L | Up to 10mm |

UV Inspection Equipment

UV inspection tools enhance visibility of fluorescent particles during testing procedures. The range includes:

- LED UV torches with 365nm wavelength

- Stationary UV inspection lamps

- Battery-operated portable lights

- UV meters for intensity measurement

- UV protective eyewear

- White light meters

| Equipment Type | Light Intensity | Battery Life | Coverage Area |

|---|---|---|---|

| Portable LED | 4,500 µW/cm² | 8-10 hours | 30cm circle |

| Fixed Mount | 6,000 µW/cm² | N/A | 45cm circle |

Each UV inspection tool meets BS EN ISO 9934-3 standards for magnetic particle testing requirements, making them suitable for industrial applications in the UK.

Where to Buy Magnaflux in the UK

Looking for genuine Magnaflux products in the UK, Call Norsemen/Welder’s Choice 0n 028 9046 0541. We ship across the UK and Ireland.

Authorised Distributor for Magnaflux?

As a certified Magnaflux distributor we offer:

- Direct technical support from trained specialists

- Complete product documentation verification

- Calibration certificates for testing equipment

- Local warehousing for fast delivery

To see the full range of Magnaflux products Norsemen offers, please see Magnaflux UK.

Online Retailers

E-commerce platforms, such as Norsemen Safety provide convenient access to Magnaflux products with these benefits:

- Detailed product specifications

- Real-time stock availability

- Customer reviews from industry users

- Digital order tracking

- SSL-secured payment processing

- Product authenticity guarantees

- Technical documentation downloads

Magnaflux Products Available At Norsemen Safety

Magnaflux product prices in the UK vary based on several key factors including product type, quantity, and specific testing requirements. Understanding these pricing elements helps in making cost-effective purchasing decisions.

Welding Testing

This Magnaflux product allows for there to be a reduced operator arm and wrist fatigue while testing welds. This Yoke generates a strong AC magnetic field for the detection of surface indications during magnetic particle resting. Featuring a field-swappable cord and isolated trigger switch this is the best all round weld testing.

Magnaflux EV6000 Hand-Held LED UV Lamp

This Magnaflux product allows for portable NDT applications like fluorescent penetrant testing and magnetic Particle Inspections. This product features a uniform beam with no hot-spots and a 23cm wide beam, this is 33% wider than the next widest hand-held UV lamp industry.

This is a bright white, non-aqueous developer that creates an opaque white background allowing for high-contrast penetrant testing and quickly draws penetrant out to create stronger, clearer indications for better inspection and reliability.

Important Considerations Before Purchase

Selecting the right Magnaflux equipment requires careful evaluation of several key factors. These considerations help maximise testing accuracy while meeting industry standards.

Quality Certifications

Quality certifications validate Magnaflux products for industrial use in the UK. Each product must carry BS EN ISO 9934-2 certification for magnetic particle materials. Look for these specific compliance markers:

- CE marking on all equipment components

- ASTM E1444/E1444M compliance documentation

- NDT quality system certification to ISO 9001:2015

- Batch testing certificates for magnetic particles

- Material Safety Data Sheets (MSDS) for all consumables

Conclusion

We’ve explored the essentials of buying Magnaflux products in the UK from trusted suppliers and online retailers. Getting your hands on genuine magnetic particle testing equipment doesn’t have to be complicated when you know where to look and what to consider.

Remember that investing in quality Magnaflux equipment through authorised channels is crucial for maintaining testing accuracy and meeting industry standards. Whether you’re choosing a complete testing kit or individual components our guide helps you make informed decisions.

For the best results, we recommend working with verified UK distributors who offer comprehensive support packages and proper documentation. This ensures you’ll get reliable equipment backed by expert technical assistance whenever you need it. Have questions or need assistance? Contact us today!

Frequently Asked Questions

What is Magnaflux testing?

Magnaflux testing is a non-destructive testing method that uses magnetic particles to detect surface and near-surface flaws in ferromagnetic materials. It’s widely used in manufacturing, aerospace, and automotive industries for quality control and safety inspections.

How deep can Magnaflux testing detect flaws?

Magnaflux testing can detect surface cracks as small as 0.001 inches and subsurface flaws up to 0.25 inches deep. This makes it highly effective for identifying both visible and hidden defects in ferromagnetic materials.

What’s included in a Magnaflux testing kit?

A complete Magnaflux testing kit typically includes dry and wet magnetic particles, magnetic field indicators, and cleaning solutions. Some kits also come with UV inspection equipment, depending on the specific testing requirements.

Are Magnaflux products compliant with UK standards?

Yes, Magnaflux products comply with UK standards, including BS EN ISO 9934-3 and CE marking requirements. They meet industry-specific quality certifications and NDT system requirements for industrial applications.

What support services are available for Magnaflux equipment?

UK suppliers offer comprehensive support services including on-site installation, operator training, remote troubleshooting, and regular calibration. Both standard and premium support packages are available with varying response times and service levels.

How is pricing determined for Magnaflux products?

Pricing varies based on product type, quantity, and specific testing requirements. Factors affecting cost include the choice between wet or dry method materials, UV inspection equipment, and additional elements such as calibration certificates and training documentation.

What should I consider before buying Magnaflux equipment?

Key considerations include quality certifications, technical support availability, compliance with industry standards, and ongoing maintenance requirements. Evaluate both immediate costs and long-term support needs to ensure optimal equipment performance.