Have you ever found yourself scratching your head over which welding method to choose? We’ve all been there! MIG welding vs arc welding is like the chocolate and vanilla of the welding world – both popular, but each with its own unique flavour.

Key Takeaways

- MIG welding offers faster, cleaner welds and is easier to learn, but requires more complex equipment and is less suitable for outdoor use.

- Arc welding is more versatile, portable and cost-effective, but has a steeper learning curve and slower welding speed.

- MIG welding produces smoother welds, while arc welding often provides stronger joints for heavy-duty applications.

- MIG welding equipment is generally more expensive, but arc welding may have higher ongoing costs for consumable electrodes.

- Both methods require proper safety gear, but MIG welding involves additional precautions for handling shielding gas cylinders.

- Norsemen/Welder’s Choice supplies all the equipment and welding consumables for mig welding, arc welding (Stick/MMA) and Tig Welding.

Understanding MIG Welding vs Arc Welding

MIG Welding: The Smooth Operator

MIG welding, or Metal Inert Gas welding, is like spreading butter on toast – smooth and continuous. It’s a process that uses a wire electrode fed through a welding gun, creating an electric arc between the wire and the workpiece. This arc melts both the wire and the base metal, forming a weld that’s as neat as a pin.

Ever tried to keep a steady hand while drawing a long, unbroken line? That’s what MIG welding feels like. The wire feeds automatically, allowing for a consistent weld bead.

Arc Welding: The Versatile Veteran

Arc welding, also known as Shielded Metal Arc Welding (SMAW), is the Swiss Army knife of welding. It’s been around the block a few times and knows a thing or two about joining metals. This method uses a consumable electrode covered with flux, which burns off during welding to protect the molten metal from atmospheric contamination.

Imagine you’re at a barbecue, and your mate hands you a stick with a marshmallow on the end. That’s a bit like an arc welding electrode – except instead of toasting marshmallows, you’re fusing metal. And let’s be honest, that’s way cooler!

Equipment: The Tools of the Trade

MIG welding requires a few more bells and whistles than its arc counterpart. You’ll need a wire feeder, a welding gun, and a gas cylinder. It’s like preparing for a fancy dinner party – you need all the right cutlery and crockery to make it work.

Arc welding, on the other hand, is more of a minimalist. It doesn’t need a separate shielding gas, as the flux on the electrode does all the heavy lifting. It’s the backpacker of welding methods – lightweight and ready for action.

The Basics of MIG Welding

MIG welding, short for Metal Inert Gas welding, is a popular arc welding process that uses a continuous wire electrode. It’s like having a never-ending supply of metal to join two pieces together seamlessly.

How MIG Welding Works

MIG welding operates on a simple principle: a wire electrode is fed through a welding gun, creating an electric arc between the wire and the workpiece. This arc melts both the wire and the base metal, forming a weld pool. The process is shielded by an inert gas, typically argon or a mix of argon and CO2, which protects the weld from atmospheric contamination.

Think of it as a hot glue gun for metal. The wire is like the glue stick, continuously feeding through the gun, while the electric arc acts as the heating element. The shielding gas is your invisible helper, keeping pesky air particles away from your masterpiece.\

Advantages of MIG Welding

- Speed: MIG welding is faster than many other welding methods. It’s like the fast food of the welding world – quick and efficient.

- Clean welds: The process produces neat, spatter-free welds. No more messy clean-ups!

- Versatility: MIG welding works on various metals and thicknesses. It’s the Swiss Army knife of welding techniques.

- Easy to learn: Even beginners can pick up MIG welding relatively quickly. It’s like riding a bike – once you get the hang of it, you’re off!

- Continuous welding: The wire feed allows for long, uninterrupted welds. No need to stop and start like with stick welding.

Draw Backs of Mig Welding

- Equipment complexity: MIG welding requires more equipment than some other methods. It’s a bit like needing a full kitchen to make a gourmet meal.

- Outdoor restrictions: Wind can blow away the shielding gas, making outdoor welding tricky. It’s not the best choice for your backyard projects on a blustery day. Gasless mig wire is a great option for outdoor welding.

- Power requirements: MIG welders often need more power than other welding machines. They’re the energy guzzlers of the welding world.

- Material limitations: While versatile, MIG welding isn’t ideal for all metals. It’s like trying to spread cold butter – some materials just won’t cooperate.

- Cost: The initial setup for MIG welding can be pricey. It’s an investment, much like buying a good set of power tools.

The Fundamentals of Arc Welding

Arc welding, also known as Shielded Metal Arc Welding (SMAW) or stick welding, is a popular metal joining technique. It’s like using a giant, superheated pencil to draw metal together. Let’s dive into the nitty-gritty of this welding method.

How Arc Welding Works

Arc welding creates an electric arc between a consumable electrode (the “stick“) and the workpiece. This arc generates enough heat to melt the metal, allowing two pieces to join when cooled. The electrodes have a flux coating that protects the weld area from atmospheric gases, eliminating the need for external shielding gas.

Ever tried toasting marshmallows? Arc welding is similar, but instead of a campfire, you’re using electricity to melt metal. The stick electrode is like your marshmallow stick, but much hotter and more precise.

Advantages of Arc Welding

- Versatility: Arc welding works in various environments, including windy or outdoor conditions.

- Portability: The equipment is relatively lightweight and easy to move around.

- Cost-effectiveness: Arc welders and electrodes are generally less expensive than other welding equipment.

- Simplicity: With fewer components, there’s less to go wrong.

Have you ever needed to fix something in a tricky spot? Arc welding might be your go-to solution. It’s like having a Swiss Army knife in your welding toolkit – ready for almost any situation.

Disadvantages of Arc Welding

- Skill requirement: It takes practice to master the technique.

- Slower speed: Compared to some other methods, arc welding can be time-consuming.

- Frequent electrode changes: You’ll need to pause work to replace electrodes.

- Slag removal: After welding, you’ll need to chip away the slag covering.

Remember the last time you tried to learn a new skill? Arc welding can feel like that – a bit challenging at first, but rewarding once you’ve got the hang of it.

Comparing MIG Welding vs Arc Welding

When it comes to welding, MIG welding vs arc welding are like two different flavours of ice cream. Each has its own unique taste and texture, appealing to different palates. Let’s dive into the nitty-gritty of these welding methods and see how they stack up against each other.

Ease of Use and Learning Curve

MIG welding is the friendly neighbour of the welding world. It’s like learning to ride a bike with training wheels – you’ll be zipping along in no time. The automatic wire feed makes it a breeze to maintain a consistent weld, much like cruise control in your car. On the other hand, arc welding is more like mastering a unicycle. It’s trickier to get the hang of, requiring a steady hand and a keen eye to manage the electrode. But once you’ve got it down, you’ll feel like a proper welding acrobat!

Have you ever tried to write with your non-dominant hand? That’s a bit what arc welding feels like at first. But don’t worry, with practice, you’ll be signing your name (or rather, your welds) with flourish in no time.

Weld Quality and Strength

MIG welding produces welds smoother than a baby’s bottom. It’s like spreading butter on hot toast – smooth, even, and oh-so-satisfying. However, when it comes to strength, arc welding often takes the cake. It’s like the difference between a handshake and a bear hug – both get the job done, but one’s got a bit more oomph behind it.

Versatility and Applications

MIG welding is like your trusty Swiss Army knife – it’s handy for a wide range of jobs and materials. From car bodywork to household repairs, it’s got you covered. Arc welding, however, is more like that old, sturdy toolbox in your grandad’s shed. It might not be as flashy, but it can handle tough jobs in various conditions, even outdoors on a blustery day.

Cost Considerations: MIG Welding vs Arc Welding

When it comes to welding, we’re all looking for the best bang for our buck, aren’t we? Let’s dive into the cost considerations of MIG welding vs arc welding – it’s like comparing apples and oranges, but with sparks!

Equipment Costs

MIG welders are the fancy sports cars of the welding world. They’re sleek, complex, and come with a heftier price tag. With their wire feeders and gas delivery systems, MIG welders can cost 2-4 times more than their arc welding counterparts. It’s like buying a smartphone instead of a basic mobile – you’re paying for the bells and whistles.

Arc welders, on the other hand, are the trusty bicycles of welding. They’re simple, durable, and won’t break the bank. With fewer moving parts, arc welders are not only cheaper to buy but also easier on the wallet when it comes to maintenance. It’s like choosing between a Swiss Army knife and a simple pocketknife – both get the job done, but one’s a bit more straightforward.

Consumables

Here’s where things get interesting! MIG welding uses consumable wire, which isn’t too pricey on its own. But wait, there’s more! You’ll need shielding gas too, usually a mix of argon and carbon dioxide. It’s like needing both petrol and oil for your car – the costs can add up.

Arc welding, however, keeps things simple with its flux-coated electrodes. These little sticks are like the all-in-one meals of the welding world – everything you need in one package.

Have you ever tried to budget for a DIY project only to find hidden costs popping up everywhere? Welding can be a bit like that, especially when you’re just starting out. But don’t worry, we’ve all been there!

Remember, the cheapest option isn’t always the most cost-effective in the long run. It’s about finding the right balance for your needs and budget. So, whether you’re team MIG welding vs team Arc welding, make sure you’ve crunched all the numbers before making your choice. After all, in welding as in life, it’s not just about the initial investment – it’s about the long-term value.

Safety Aspects of MIG Welding vs Arc Welding

Let’s dive into the safety aspects of MIG welding vs arc welding. Think of welding safety as putting on your seatbelt before driving – it’s essential and non-negotiable.

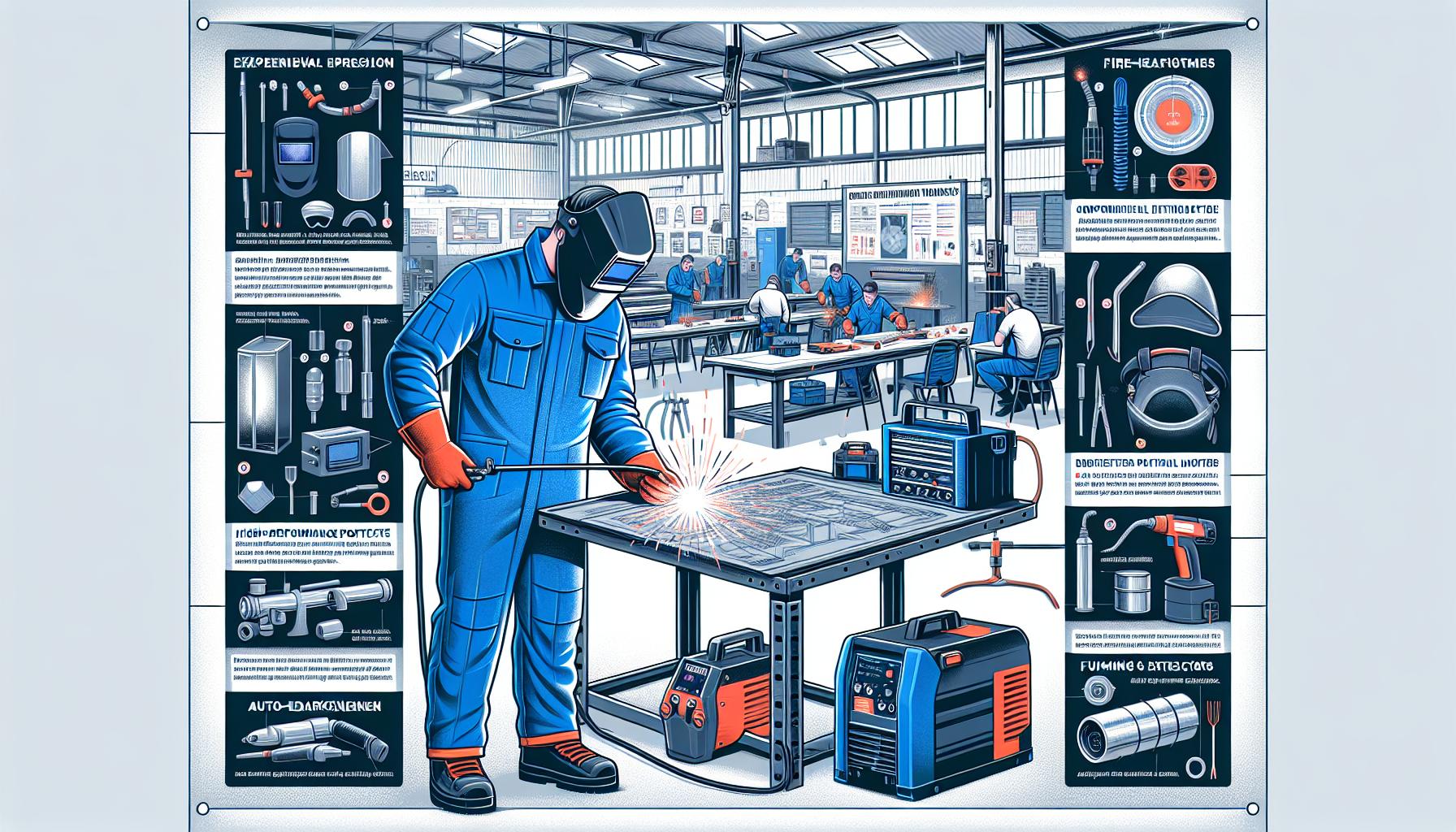

Equipment and Setup

MIG welding is like preparing a gourmet meal – it requires more ingredients and tools. The setup includes a welding gun, wire feeder, and gas cylinder. This complexity can increase the risk of tripping or equipment damage. It’s a bit like having too many cooks in the kitchen!

On the other hand, arc welding is more like making a sandwich – simple and straightforward. The equipment is minimal, reducing the chances of accidents due to complex setups.

Personal Protective Equipment (PPE)

When it comes to PPE, both MIG welding vs arc welding demand respect. MIG welding produces less slag and spatter, but it’s not a free pass to skimp on protection. Arc welding, meanwhile, is like a fireworks display – lots of sparks and slag!

For both methods, we need:

- Welding helmet: Your face’s best friend

- Gloves: Because who wants toasty fingers?

- Protective clothing: Fashion meets function

Have you ever tried to explain your welding gear to non-welders? It’s like describing a superhero costume – they just don’t get it!

Shielding Gas Considerations

MIG welding uses shielding gas, typically a mix of argon and carbon dioxide. Handling gas cylinders is like juggling – it requires care and attention. One wrong move, and you might find yourself chasing a runaway cylinder down the workshop!

Arc welding, however, doesn’t need separate shielding gas. The flux coating on the electrode does the job, making it a bit less complicated in this regard.

Remember, safety in welding isn’t just about protecting yourself – it’s about keeping your workshop mates safe too. After all, we’re all in this together, right?

Choosing Between MIG Welding vs Arc Welding

Let’s start with MIG welding. It’s like driving an automatic car – smooth, easy to handle, and perfect for beginners. You’ve got a wire that feeds automatically, like a never-ending stream of molten metal. Fancy, right? But remember, it’s a bit fussy about where it works. Wind is its enemy, so it’s best kept indoors or in sheltered areas.

Arc welding is more like riding a bike. It might take a bit more skill to master, but once you’ve got it, you can take it anywhere. It’s the sturdy, reliable friend that’s always ready for an adventure. Plus, it’s not picky about the weather – rain or shine, it’s ready to weld.

But how do you choose? Well, let’s break it down:

- What are you welding? Thin sheets? Go MIG. Thick, rusty metal? Arc’s your mate.

- Where are you welding? Indoors? MIG’s happy there. Outdoors? Arc won’t let you down.

- How’s your budget looking? MIG’s initial cost might make your wallet wince, but arc keeps things simple and affordable.

We’re all part of this welding community, learning and growing together. What’s your go-to welding method? Have you had any hilarious welding mishaps? Share your stories with us!

Conclusion

Both MIG welding vs arc welding have their place in the world of metal joining. We’ve explored their unique characteristics strengths and limitations. MIG welding shines with its ease of use and clean welds while arc welding stands out for its versatility and ruggedness. Your choice ultimately depends on your specific needs project requirements and budget. Whether you opt for the smooth consistency of MIG or the robust reliability of arc welding remember that mastering either technique takes practice and patience. Choose wisely and weld with confidence!

Frequently Asked Questions

What is MIG welding?

MIG welding, or Metal Inert Gas welding, is a smooth and continuous welding process that uses a wire electrode fed through a welding gun. It creates an electric arc that melts both the wire and the base metal to form a neat weld. The process is shielded by an inert gas, typically argon or a mix of argon and CO2, to protect the weld from contamination.

What is arc welding?

Arc welding, also known as Shielded Metal Arc Welding (SMAW), is a versatile welding method that uses a consumable electrode covered with flux. It creates an electric arc between the electrode and the workpiece, generating enough heat to melt the metal for joining. The flux on the electrode protects the molten metal from contamination during the welding process.

Which welding method is easier to learn?

MIG welding is generally considered easier to learn and more user-friendly for beginners. It offers a smooth, continuous process with automatic wire feeding, making it easier to maintain a consistent weld bead. Arc welding, on the other hand, requires more skill and practice to master the technique of maintaining the correct arc length and speed.

What are the main advantages of MIG welding?

The main advantages of MIG welding include its speed, clean welds, versatility, and ease of learning for beginners. It produces smooth, spatter-free welds and can be used on a variety of metals. MIG welding is also faster than arc welding and allows for longer continuous welds due to its automatic wire feed system.

What are the benefits of arc welding?

Arc welding offers several benefits, including versatility in various environments, portability, cost-effectiveness, and simplicity due to fewer components. It can be used outdoors and in windy conditions, making it suitable for field work. Arc welding equipment is also generally less expensive and more portable than MIG welding equipment.

Which welding method is more cost-effective?

Arc welding is generally more cost-effective in terms of initial equipment costs and consumables. Arc welders are simpler and more affordable, often likened to “trusty bicycles” in the welding world. While MIG welding requires additional costs for shielding gas, arc welding’s flux-coated electrodes are more straightforward and economical.

How do MIG welding vs arc welding compare in terms of weld quality?

MIG welding typically produces smoother, cleaner welds with less spatter. However, arc welding often results in stronger joints, especially on thicker materials. The quality of the weld in both methods depends on the skill of the welder and the specific application. MIG welding is preferred for thin sheets, while arc welding excels on thicker, rusty metals.

What safety considerations are important for both welding methods?

Both MIG and arc welding require proper personal protective equipment (PPE), including welding helmets, gloves, and flame-resistant clothing. Arc welding generates more sparks and slag, necessitating extra caution. MIG welding involves handling pressurised gas cylinders, which requires additional safety measures. Proper ventilation is crucial for both methods to avoid inhaling harmful fumes.

How do I choose between MIG welding vs arc welding?

Choose based on your specific welding needs and budget. Consider factors like the type and thickness of metal, working environment (indoor vs outdoor), frequency of use, and your skill level. MIG welding is ideal for thin sheets and indoor work, while arc welding is better for thick, rusty metal and outdoor conditions. Evaluate your requirements carefully to select the most suitable method for your projects.