Full Face Mask Moldex UK: Complete Safety Guide 2025

Key Takeaways

- Full face mask Moldex UK provide comprehensive protection with their triple-seal technology and meets strict British safety standards including EN 136:1998 requirements

- Two primary models are available in the UK market: Series 9000 (heavy-duty) and Series 7000 (medium-duty), offering different protection levels from FFP1 to FFP3 with filtration rates of 80% to 99%

- The masks feature medical-grade silicone seals, polycarbonate lenses, and thermoplastic components engineered for durability and comfort during extended wear

- Regular maintenance is crucial, including fit testing every 12 months, cleaning after each use, and proper storage between 5-25°C in sealed containers

- UK prices range from £90-£180 for masks and £15-£45 for filters, available through authorised safety equipment distributors with typical delivery within 1-3 business days

Respiratory protection plays a vital role in keeping workers safe across countless industries in the UK. We’ve seen how full face masks from Moldex have become essential equipment for professionals working in environments with airborne hazards.

If you’re looking to protect yourself or your team from dangerous particles dust and fumes you’ll want to understand what makes these masks so effective. We’ll explore why Moldex full face masks stand out in the UK market and help you discover the features that matter most for your specific needs. From their comfortable fit to their reliable filtration systems, these masks offer comprehensive protection for challenging work environments.

Understanding Moldex Full Face Masks

Moldex full face masks offer comprehensive respiratory protection through advanced filtration technology and ergonomic design. These masks protect workers from hazardous airborne particles while maintaining comfort during extended wear periods.

Key Features and Protection Levels

The Moldex full face mask series incorporates essential protective elements:

- Triple-seal technology creates an airtight barrier against particulates dust vapours

- Wide-view polycarbonate lens provides 180-degree visibility

- Dual filter ports enable balanced air distribution

- Quick-release straps for fast donning removal

- Speech diaphragm enhances clear communication

Protection ratings range from FFP1 to FFP3:

| Protection Level | Filtration Rate | Suitable For |

|---|---|---|

| FFP1 | 80% | Non-toxic dusts fibres |

| FFP2 | 94% | Metal fumes toxic particles |

| FFP3 | 99% | Harmful biological agents chemicals |

Materials and Construction Quality

The masks feature premium materials engineered for durability:

- Medical-grade silicone face seal prevents skin irritation

- Impact-resistant lens meets EN166 standards

- Thermoplastic elastomer body withstands chemical exposure

- Reinforced filter connections prevent air leakage

- Lightweight components reduce user fatigue

Construction specifications include:

| Component | Material | Benefits |

|---|---|---|

| Face Seal | Silicone | Comfort flexibility longevity |

| Lens | Polycarbonate | Impact resistance clarity |

| Head Harness | Elastic textile | Secure fit adjustability |

| Filter Housing | Thermoplastic | Chemical resistance durability |

The materials undergo strict quality testing to maintain consistent performance standards in demanding work environments.

Popular Moldex Full Face Mask Models in the UK

Moldex offers two primary full face mask series in the UK market, each designed for specific workplace protection requirements. These models combine advanced filtration with ergonomic features to meet diverse industrial safety needs.

Series 9000 Full Face Mask

The Moldex Series 9000 full face mask delivers comprehensive respiratory protection in challenging environments. Its distinctive features include:

- Triple-flange silicone seal creating an airtight barrier

- Extra-wide 180° viewing panel with anti-fog coating

- Pre-installed speech diaphragm for clear communication

- Compatible with P1 P2 P3 particulate filters

- 5-point head harness for secure positioning

Protection levels for the Series 9000:

| Filter Class | Protection Level | Applications |

|---|---|---|

| FFP3 | 99.95% filtration | Heavy dust, metal fumes |

| Gas/Vapour | ABEK1 | Chemical processing |

| Combined | ABEK1P3 | Multiple hazards |

Series 7000 Half Face Mask

The Series 7000 mask presents a lightweight alternative for medium-duty applications. Key attributes include:

- Low-profile design reducing neck strain

- Dual filter ports for balanced air distribution

- Quick-release buckles for easy removal

- Replaceable lens protection films

- Four-point head strap system

| Feature | Specification | Benefit |

|---|---|---|

| Weight | 370g | Reduced fatigue |

| Lens material | Polycarbonate | Impact resistance |

| Face seal | Medical silicone | Extended comfort |

| Filter types | P1/P2/P3, Gas | Versatile protection |

Safety Standards and Certifications

Moldex full face masks meet rigorous safety standards established by UK regulatory bodies. These certifications validate the masks’ effectiveness in protecting users from workplace respiratory hazards.

UK and EU Compliance Requirements

Full face masks sold in the UK comply with EN 136:1998 standards for respiratory protective devices. The certification process involves testing for:

- Impact resistance at extreme temperatures (-30°C to +60°C)

- Flame resistance with 6 seconds direct exposure

- Heat radiation protection up to 900°C

- Chemical permeation resistance against common industrial substances

- Carbon dioxide content below 1% in inhaled air

- Field of vision exceeding 70% of natural sight range

The masks also maintain CE marking compliance under UK CA requirements post-Brexit, demonstrating adherence to:

- PPE Regulation (EU) 2016/425

- UKCA marking standards BS EN 136:1998

- ISO 9001 quality management systems

Protection Classes Explained

Moldex full face masks offer three distinct protection classes:

| Protection Class | Filtration Rate | Max Inward Leakage |

|---|---|---|

| FFP1 | 80% | 22% |

| FFP2 | 94% | 8% |

| FFP3 | 99% | 2% |

Proper Fitting and Maintenance

Proper fitting and regular maintenance of Moldex full face masks maximise protection and extend the equipment’s lifespan. The following guidelines detail essential steps for achieving optimal fit and maintaining mask effectiveness.

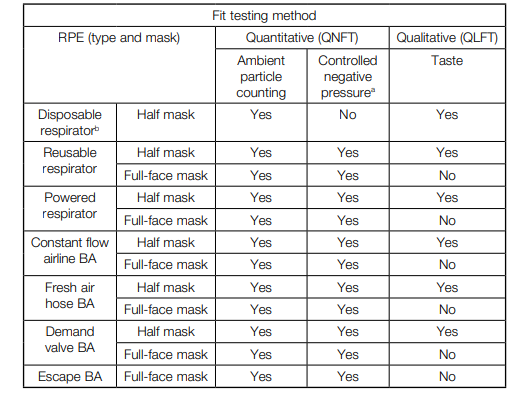

Size Selection and Fit Testing

Selecting the correct mask size starts with measuring facial dimensions from chin to nose bridge and across the widest part of the face. A fit test verifies the mask’s seal effectiveness through these steps:

- Perform a negative pressure test by blocking the filter ports and inhaling

- Complete a positive pressure test by covering the exhalation valve and exhaling

- Check for leaks by moving the head in multiple directions

- Document fit test results with date time and pass/fail status

- Repeat fit testing every 12 months or after significant facial changes

At Norsemen Safety we provide Fit testing services for those who are in Northern Ireland. To find out more information about this, contact us 02890460541.

Cleaning and Storage Guidelines

Regular cleaning maintains hygiene standards and preserves the mask’s protective qualities. Here’s a systematic approach to cleaning and storage:

- Remove filters and store separately

- Wash the mask in warm water (40°C) with mild soap

- Disinfect using approved sanitising solutions

- Rinse thoroughly with clean water

- Air dry at room temperature away from direct sunlight

| Maintenance Task | Frequency |

|---|---|

| Basic cleaning | After each use |

| Deep cleaning | Weekly |

| Seal inspection | Monthly |

| Filter replacement | As per manufacturer guidelines or when breathing resistance increases |

| Fit testing | Annually |

Where to Buy Moldex Full Face Masks in the UK

Moldex full face masks are available through several authorised distribution channels in the UK, such as Norsemen Safety.

Price Ranges and Availability

Key factors affecting availability include:

- Bulk order quantities receive priority shipping

- Standard stock levels fluctuate seasonally

- Popular filter cartridges remain consistently available

- Custom configurations require 5-7 day lead times

- Emergency orders accommodate next-day delivery options

Regular inventory updates from authorized suppliers help track real-time stock levels. Local distributors often maintain emergency supplies for immediate collection.

Conclusion

Moldex full face masks stand as a cornerstone of workplace respiratory protection in the UK. We’ve explored their advanced features ergonomic designs and strict compliance with safety standards that make them indispensable across various industries.

The combination of premium materials superior filtration technology and comprehensive protection demonstrates why these masks are trusted by professionals nationwide. Whether choosing the robust Series 9000 or the versatile Series 7000 we know that proper fitting and maintenance are crucial for optimal protection.

Through authorised UK distributors, these essential safety devices remain readily accessible to workers who need reliable respiratory protection. Moldex’s commitment to quality and safety continues to set the standard in workplace respiratory protection. Have questions or need assistance? Contact us today!

Frequently Asked Questions

What makes Moldex full face masks different from other respiratory protection?

Moldex full face masks stand out due to their triple-seal technology, 180-degree wide-view lens, and dual filter ports. They’re constructed with medical-grade silicone and impact-resistant polycarbonate, offering superior comfort and protection. The masks meet rigorous UK safety standards and provide comprehensive protection against various airborne hazards.

Which protection classes are available for Moldex full face masks?

Moldex offers three protection classes: FFP1, FFP2, and FFP3. FFP1 filters at least 80% of particles, FFP2 filters 94%, and FFP3 provides the highest protection, filtering 99% of airborne particles. The choice depends on the specific workplace hazards and risk assessment.

How often should I replace the filters on my Moldex full face mask?

Filters should be replaced when you notice increased breathing resistance, detect contaminant odour, or after 6 months of use, whichever comes first. Regular inspection of filters is essential for maintaining optimal protection levels. Follow manufacturer guidelines for specific filter types.

What maintenance is required for Moldex full face masks?

Regular maintenance includes cleaning after each use, weekly deep cleaning, and annual fit testing. Inspect seals regularly, clean with mild soap and water, and store in a cool, dry place away from direct sunlight. Check for damage to straps, lens, and seal before each use.

How do I ensure the mask fits correctly?

Perform both negative and positive pressure tests before each use. Select the appropriate size, conduct proper fit testing, and ensure all straps are correctly adjusted. The mask should create an airtight seal around your face with no gaps. Professional fit testing is recommended annually.

Are Moldex masks suitable for all workplace environments?

While Moldex masks offer comprehensive protection, they must be matched to specific workplace hazards. They’re suitable for most industrial settings, including chemical processing, construction, and manufacturing. However, always conduct a workplace risk assessment to ensure the chosen model meets your specific safety requirements.

What certifications do Moldex full face masks have?

Moldex masks comply with EN 136:1998 standards and feature UKCA marking post-Brexit. They’re certified for impact resistance, flame resistance, heat radiation protection, and chemical permeation resistance. These certifications ensure the masks meet UK safety regulations and quality management systems.