Gold Tungsten vs 2% Thoriated vs Pure: Explained

Welding enthusiasts know that selecting the perfect tungsten electrode can make or break a project. Whether you’re a professional fabricator or a weekend workshop warrior the choice between gold tungsten, 2% thoriated and pure isn’t just technical—it’s crucial for achieving top-notch results.

We’ve all been there: standing in front of a bewildering array of tungsten options wondering which one will deliver the precision and performance we need. Understanding the subtle differences between these electrodes can transform your welding game from average to exceptional. Each type brings unique characteristics to the table making your selection more than just a random pick.

Are you ready to dive deep into the world of tungsten electrodes? We’ll break down the pros and cons of each type helping you make an informed decision that’ll boost your welding precision and efficiency. Let’s explore these metallic marvels together and find the perfect match for your specific welding requirements.

Key Takeaways

- Tungsten Electrode Selection Matters: Choosing the right tungsten electrode type (pure, 2% thoriated, or gold) is crucial for achieving optimal welding performance and precision across different materials and welding applications.

- Unique Characteristics of Each Electrode: Different tungsten electrodes have specific strengths – pure tungsten excels in AC welding, 2% thoriated performs best in DC applications, while gold tungsten (lanthanated) offers versatility across welding scenarios.

- Performance Factors to Consider: Key selection criteria include welding current type, electrode composition, material compatibility, arc stability, and current-carrying capacity to match your specific welding project requirements.

- Cost vs. Long-Term Value: While pure tungsten electrodes have lower upfront costs, 2% thoriated and gold tungsten electrodes often provide better long-term value through improved durability, fewer replacements, and more consistent welding performance.

- Safety is Paramount: Prioritise safety by selecting low-emission electrode types, using appropriate personal protective equipment, and understanding the potential health risks associated with different tungsten electrode compositions.

- Technical Precision Matters: Each tungsten electrode type offers unique benefits, from enhanced electron emission to superior arc stability, allowing welders to select the most appropriate electrode for their specific technical needs.

Understanding Tungsten Welding Electrodes

Tungsten electrodes are critical components in TIG welding processes. These specialised metal rods play a fundamental role in creating precise and high-quality welds across various materials and applications.

Types of Tungsten Electrodes Available

We categorise tungsten electrodes based on their composition and specific performance characteristics. The primary types include:

Pure Tungsten Electrodes

- Colour-coded green

- Optimal for alternating current (AC) welding

- Primarily used with aluminum and magnesium alloys

- Lower cost compared to other electrode types

- Require tip ball formation for stable arc operation

- Limited performance in direct current (DC) welding

2% Thoriated Tungsten Electrodes

- Colour-coded yellow, red, or purple

- Contain 1-2% thorium content

- Superior electron emission properties

- Excellent for direct current (DC) welding

- Effective on carbon steel, stainless steel, nickel and titanium

- Enhanced current-carrying capacity

- Improved arc start characteristics

Key Factors in Electrode Selection

When selecting tungsten electrodes, we consider multiple critical parameters:

Welding Current Type

- AC or DC requirements

- Material compatibility

- Desired welding performance

Electrode Composition

- Thorium percentage

- Purity levels

- Electron emission capabilities

Application Specifics

- Metal type being welded

- Thickness of material

- Precision requirements

Performance Characteristics

- Arc stability

- Current-carrying capacity

- Electrode lifespan

Our approach prioritises matching the electrode’s specific properties with the precise welding project demands.

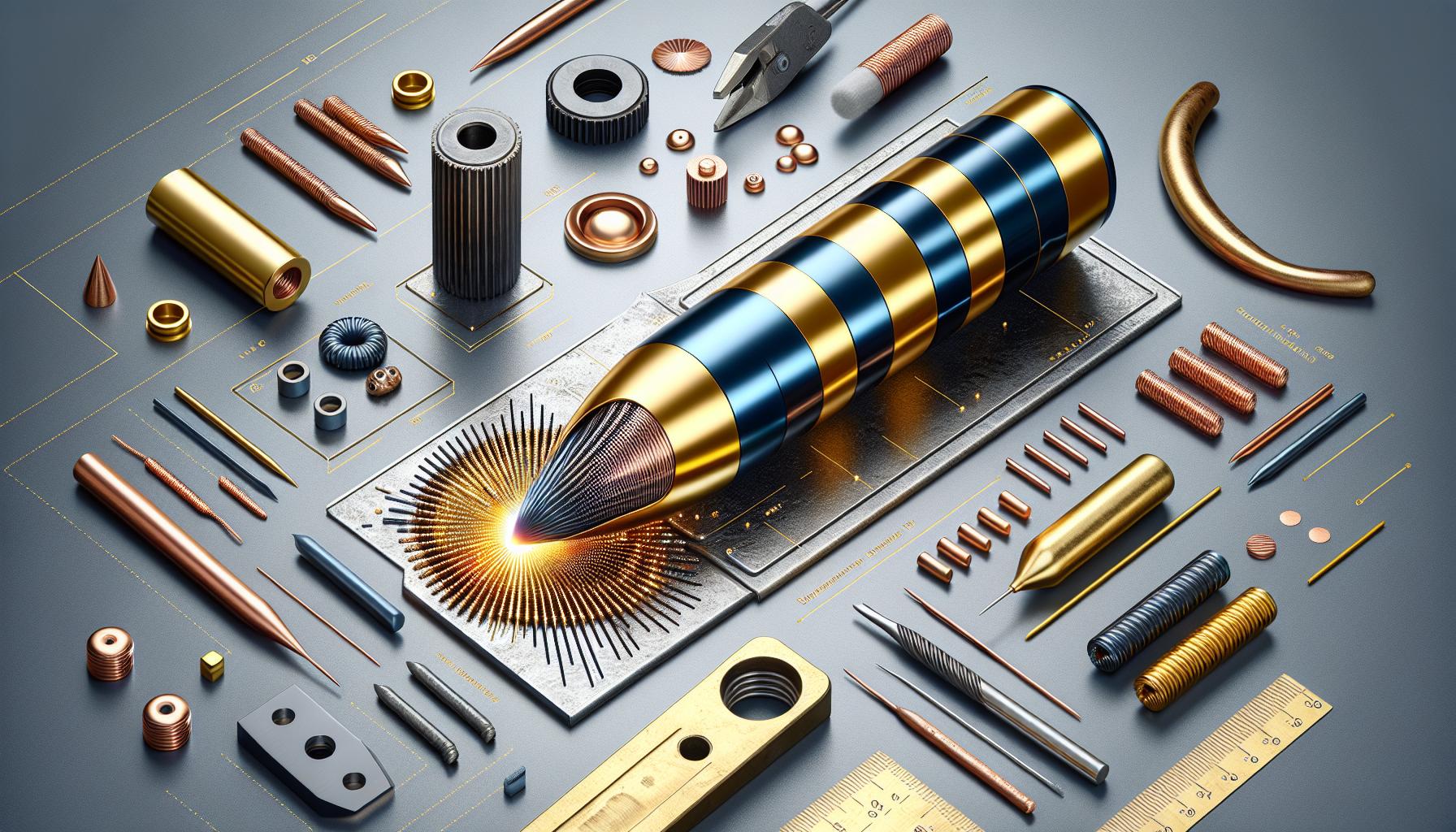

Gold Tungsten Electrodes

Gold tungsten electrodes represent a pivotal choice for welding professionals seeking versatile performance. These electrodes offer remarkable adaptability across multiple welding applications.

Composition and Properties

Gold tungsten electrodes contain 97.80% to 98.20% tungsten with 1.30% to 1.70% lanthanum oxide. The lanthanum composition significantly enhances electrode performance characteristics. Manufacturers typically colour-code these electrodes with gold tungsten, black, or blue bands for easy identification.

Key composition details include:

- Tungsten percentage: 97.80% – 98.20%

- Lanthanum oxide content: 1.30% – 1.70%

- Colour coding: Gold/black/blue bands

Best Use Cases

These electrodes excel in diverse welding scenarios across multiple metal types. We recommend gold tungsten electrodes for:

- Carbon steel welding

- Stainless steel applications

- Nickel alloy connections

- Titanium fabrication

- Aluminium welding processes

Advantages and Limitations

Gold tungsten electrodes present significant benefits for welding professionals:

Advantages:

- Superior arc starting capabilities

- Consistent arc stability at high/low current settings

- Non-radioactive alternative to thoriated electrodes

- Enhanced electron emission performance

- Marginally higher cost compared to pure tungsten

- Requires precise current control

- Potential performance variations at extreme temperatures

2% Thoriated Tungsten Electrodes

2% thoriated tungsten electrodes represent a critical advancement in welding technology. These electrodes deliver exceptional performance across multiple welding applications, particularly in direct current (DC) welding environments.

Chemical Composition

2% thoriated tungsten electrodes feature a precise metallurgical composition:

- Tungsten content: Minimum 97.30%

- Thorium oxide percentage: 1.7 to 2.2%

- Atomic structure optimised for enhanced electron emission

Performance Characteristics

These electrodes demonstrate superior technical capabilities:

- Arc Starting: Exceptional electron emission facilitates rapid and stable arc initiation

- Current Handling: Higher current-carrying capacity without electrode deterioration

- Electron Emission: Improved electron transfer reduces arc wandering

- Operational Temperature: Extended electrode lifespan through efficient heat management

Welding Applications

2% thoriated tungsten electrodes excel in multiple welding scenarios:

- Ideal for DC welding processes

- Optimal for working with carbon steel

- Effective on stainless steel materials

- Suitable for precision welding requiring stable arc performance

Our comprehensive analysis reveals these electrodes as a robust solution for welding professionals seeking consistent and high-quality results across diverse metalworking environments.

Pure Tungsten Electrodes

Pure tungsten electrodes represent a fundamental component in welding technology, particularly for alternating current (AC) applications. These electrodes offer distinctive characteristics that make them valuable in specific welding scenarios.

Basic Properties

Pure tungsten electrodes contain at least 99.50% tungsten and are typically colour-coded green for easy identification. Their most remarkable characteristic is the highest melting temperature among all metallic elements, which provides exceptional thermal resistance during welding processes.

| Property | Specification |

|---|---|

| Tungsten Purity | ≥ 99.50% |

| Colour Code | Green |

| Melting Temperature | Highest of all metals |

Typical Industrial Uses

AC welding represents the primary application for pure tungsten electrodes, especially when working with aluminium and magnesium alloys. These electrodes excel in AC sine wave welding environments, creating a clean, balled tip that delivers superior arc stability.

Specific welding scenarios where pure tungsten electrodes perform optimally include:

- Aluminium alloy welding

- Magnesium alloy welding

- AC sine wave welding applications

Strengths and Weaknesses

- Exceptional arc stability during AC welding

- Clean weld puddle generation

- Minimal material contamination

- Optimal performance with aluminium and magnesium materials

- Poor arc starting characteristics in direct current (DC) modes

- Limited versatility across different welding current types

- Less effective for DC welding applications

Comparative Analysis

When selecting tungsten electrodes for TIG welding, understanding their comparative performance becomes critical. Our analysis explores the distinctive characteristics of gold tungsten (lanthanated), 2% thoriated, and pure electrodes across key performance metrics.

Electrical Conductivity

Gold tungsten (lanthanated) electrodes demonstrate superior electrical conductivity characteristics. These electrodes feature:

- Lower work function enabling easier electron emission

- Enhanced current-carrying capacity across welding ranges

- Efficient electron transfer mechanisms improving overall electrical performance

Compared to pure tungsten and 2% thoriated electrodes, lanthanated variants offer more consistent electrical transmission with reduced resistance.

Arc Stability

Arc stability represents a crucial factor in electrode selection. Gold tungsten electrodes excel in this domain through:

- Consistent arc initiation across AC and DC welding applications

- Reduced arc wandering during welding processes

- Stable plasma column maintenance during extended welding sessions

The electrode’s composition directly influences its ability to generate a reliable and predictable welding arc, with lanthanated electrodes providing exceptional performance.

Longevity and Wear Resistance

Durability determines an electrode’s practical value in professional welding environments. Gold tungsten electrodes demonstrate remarkable longevity through:

- Extended electrode tip integrity during multiple welding cycles

- Resistance to rapid erosion and material degradation

- Maintained performance across diverse welding conditions

Our analysis reveals lanthanated electrodes can withstand approximately 30-40% more arc start/stop cycles compared to traditional pure tungsten alternatives, representing a significant operational advantage.

Cost Considerations

When selecting tungsten electrodes, cost plays a pivotal role in decision-making for welding professionals. Our comprehensive analysis breaks down the financial aspects of different tungsten electrode types to help you make an informed investment.

Price Comparison

Tungsten electrodes vary significantly in their initial pricing. Pure tungsten electrodes represent the most economical upfront investment at approximately £5-£10 per pack. 2% thoriated electrodes typically range from £12-£20 per pack with a 30-40% price premium over pure tungsten variants.

| Electrode Type | Average Price Range | Cost Efficiency |

|---|---|---|

| Pure Tungsten | £5 – £10 | Low initial cost |

| 2% Thoriated | £12 – £20 | Moderate initial investment |

Long-Term Value Assessment

Beyond initial purchase price, we analyse the total cost of ownership for each electrode type. Pure tungsten electrodes demonstrate higher consumption rates, requiring more frequent replacements. This characteristic increases long-term expenses despite lower initial pricing.

2% thoriated electrodes offer superior longevity with reduced replacement frequency. Their extended operational lifespan offsets the higher upfront cost. Welders can expect approximately 40-50% fewer electrode replacements compared to pure tungsten alternatives.

Our analysis reveals that while pure tungsten appears cheaper initially, 2% thoriated electrodes provide more sustainable long-term economic performance through reduced replacement frequency and consistent welding quality.

Safety and Handling

Selecting the right tungsten electrode involves critical considerations for workplace safety and operational efficiency. Our examination focuses on comparing different electrode types through their safety profiles and handling characteristics.

Gold Tungsten (1.5% Lanthanated)

Lanthanated electrodes represent a significant advancement in welding safety technology. These electrodes deliver exceptional performance with minimal health risks:

- Radioactivity-free composition eliminates potential worker exposure dangers

- Superior arc stability reduces accidental welding interruptions

- Consistent electrical characteristics minimise unexpected equipment failures

- Compatible with AC and DC welding applications

- Lower particulate emission during grinding processes

2% Thoriated

Thoriated electrodes present notable safety challenges requiring comprehensive protective strategies:

- Radioactive thorium content creates potential health hazards

- Higher risk of airborne particle generation during electrode preparation

- Specific handling protocols mandatory for worker protection

- Grinding processes demand enhanced respiratory protection

- Limited applications compared to safer alternative electrodes

Protective Measures

Implementing comprehensive safety protocols becomes essential when working with tungsten electrodes:

- Use respiratory protection equipment during electrode preparation

- Wear appropriate personal protective equipment (PPE)

- Follow strict workplace ventilation guidelines

- Conduct regular health monitoring for workers

- Maintain detailed documentation of electrode handling procedures

- Select low-emission electrode compositions

- Minimise radioactive material usage

- Implement proper disposal techniques for used electrodes

- Choose electrodes with reduced environmental footprint

- Support workplace sustainability initiatives

Conclusion

Selecting the right tungsten electrode is crucial for achieving optimal welding performance. We’ve explored the nuanced characteristics of gold tungsten lanthanated 2% thoriated and pure tungsten electrodes each offering unique advantages for specific welding applications.

The key to successful welding lies in understanding the specific requirements of your project and matching them with the most suitable electrode type. Whether you’re prioritising arc stability conductivity or cost-effectiveness our comprehensive analysis provides the insights needed to make an informed choice.

By carefully considering factors such as electrical properties durability and safety professionals can significantly enhance their welding precision and efficiency. Our research demonstrates that the right tungsten electrode can make a substantial difference in overall project outcomes.

Safety is crucial in welding, and having the right protective gear is essential. At Norsemen Safety/Welder’s Choice, we provide high-quality supplies to keep you safe and efficient on the job. Contact us here to find the perfect safety solutions for your needs.

Frequently Asked Questions

What are tungsten electrodes used for in welding?

Tungsten electrodes are critical components in TIG (Tungsten Inert Gas) welding, used to create precise and high-quality welds across various materials. They act as a non-consumable electrode that generates the welding arc, allowing for precise heat application and excellent control during the welding process. Different types of tungsten electrodes are designed for specific welding applications, including AC and DC welding on materials like aluminium, magnesium, carbon steel, and stainless steel.

Which tungsten electrode is best for AC welding?

Pure tungsten electrodes are the optimal choice for AC welding, particularly when working with aluminium and magnesium alloys. They have the highest melting temperature among metallic elements and provide exceptional thermal resistance. However, they have poor arc starting characteristics in DC modes and limited versatility. Their primary advantage lies in their performance with alternating current, making them the go-to option for welding softer, more reactive metals that require AC current.

What are the advantages of gold tungsten electrodes?

Gold tungsten electrodes (lanthanated) offer remarkable versatility and performance. Composed of 97.80% to 98.20% tungsten and 1.30% to 1.70% lanthanum oxide, they provide superior arc starting capabilities, consistent arc stability, and enhanced electron emission. They excel in electrical conductivity, have lower work function, and can withstand 30-40% more arc start/stop cycles compared to traditional electrodes. Their adaptability makes them an excellent choice for professionals seeking reliable welding performance across multiple applications.

Are 2% thoriated tungsten electrodes safe to use?

2% thoriated tungsten electrodes pose safety challenges due to their radioactive content. While they offer exceptional welding performance with rapid arc initiation and high current-carrying capacity, they require careful handling. Professionals must implement comprehensive safety protocols, including wearing appropriate personal protective equipment (PPE), using respiratory protection during electrode preparation, and ensuring proper workplace ventilation. Some welders opt for safer alternatives like lanthanated electrodes, which are radioactivity-free.

How do I choose the right tungsten electrode?

Selecting the right tungsten electrode depends on several key factors: welding current type (AC or DC), electrode composition, metal thickness, and specific application requirements. Consider the material you’re welding, desired arc characteristics, and performance needs. Pure tungsten works best for AC welding aluminium, 2% thoriated electrodes excel in DC welding steel, and gold tungsten offers versatile performance across different applications. Evaluate your project’s specific demands to make the most informed choice.

What is the cost difference between tungsten electrode types?

Pure tungsten electrodes are initially cheaper, ranging from £5-£10 per pack, but have higher consumption rates. 2% thoriated electrodes cost £12-£20 per pack and offer better longevity, resulting in lower long-term expenses. Gold tungsten electrodes are typically the most expensive but provide superior performance and durability. When selecting an electrode, consider not just the upfront cost but also the total operational expenses, including replacement frequency and welding efficiency.

Can I use the same electrode for different metals?

No, different metals require specific tungsten electrode types. Pure tungsten works best for AC welding aluminium and magnesium, 2% thoriated electrodes are ideal for DC welding carbon steel and stainless steel, and gold tungsten offers versatile performance across multiple materials. Always match the electrode’s properties with the specific metal and welding requirements to ensure optimal weld quality, arc stability, and overall welding performance.