Understanding TIG Welding How It Works and When to Use It

TIG Welding How It Works and When to Use It – Have you ever wondered what TIG welding is and how a TIG welder works?

TIG Welding How It Works – We will explore the ins and outs of TIG welding, including the purpose of the TIG welding torch, the role of the tungsten electrode, and how the gas flow affects the welding process.

We will also discuss when you should use a TIG welder, what materials can be welded with it, and the advantages and disadvantages of TIG welding.

We will walk you through the steps of TIG welding and outline important safety precautions to take.

So, grab your protective gear and let’s dive into the world of TIG welding!

What Is TIG Welding?

TIG welding, also known as tungsten inert gas (TIG) welding or gas tungsten arc welding (GTAW), is a highly precise welding process that utilises a non-consumable tungsten electrode to produce the weld. This technique requires specialised equipment and a high level of skill to weld various types of metals with exceptional control and minimal spatter.

How Does a TIG Welder Work?

A TIG welder operates by creating an electric arc between a non-consumable tungsten electrode and the workpiece, with the welding current and inert gas such as argon playing crucial roles in the process. The welder can add a filler rod to the weld pool to strengthen the joint as needed.

What Is the Purpose of the TIG Welding Torch?

The TIG welding torch is designed to provide precise control over the arc length and torch angle, which are crucial for achieving high-quality welds.

This control is made possible by the ergonomic design of the torch, which typically consists of a handle, a torch body, a ceramic cup, a collet, a collet body, and a tungsten electrode. The handle allows the welder to comfortably grip the torch, while the torch body houses the internal components that regulate the shielding gas flow and electrical current. The ceramic cup surrounds the electrode and guides the gas flow to protect the weld pool.

By offering a balanced weight distribution and ease of manoeuvrability, the TIG welding torch enables welders to maintain steady control over the welding arc, resulting in precise, clean welds.

What Is the Role of the Tungsten Electrode?

The tungsten electrode in TIG welding is a non-consumable component that maintains the arc and directs heat into the weld pool.

Tungsten is a popular choice for TIG welding due to its unique properties. Tungsten has a high melting point of 3,422 degrees Celsius, making it resistant to heat and ensuring long-lasting performance. Tungsten has low thermal expansion, meaning it maintains its shape even under extreme temperatures, crucial for maintaining a stable arc during welding.

Different types of tungsten electrodes are available, including pure tungsten, thoriated, ceriated, lanthanated, and zirconiated electrodes, each with distinct characteristics influencing welding performance and quality. The choice of tungsten electrode can affect factors such as arc stability, weld penetration, and contamination resistance, ultimately impacting the final weld quality.

How Does the Gas Flow Affect the Welding Process?

In TIG welding, the flow of inert gas, typically argon, is crucial for shielding the weld area from oxidation and contamination.

Maintaining a consistent and adequate gas flow during the welding process is essential to create a protective barrier to prevent the molten metal from reacting with the surrounding atmosphere. This shielding effect minimises the formation of oxides and ensures that the weld pool remains clean, resulting in strong and high-quality welds.

Different types of gases, such as helium and carbon dioxide, can also be used depending on the specific requirements of the welding project. Helium, for instance, provides better penetration, while carbon dioxide is often used for its cost-effectiveness and better wetting properties.

Want to reduce you’re tig welding gas usage? Watch this video and give us a call.

When Should You Use a TIG Welder?

TIG welding is particularly suitable for projects that require high levels of precision and aesthetic quality, making it ideal for welding thin materials and achieving clean, visually appealing welds.

What Materials Can Be Welded with a TIG Welder?

TIG welding is versatile and can be used to weld a wide range of materials, including aluminium, stainless steel, magnesium, copper, brass, bronze, and even gold.

These materials each have unique properties that make TIG welding an ideal choice for their joining processes. Aluminium, known for its lightweight properties, can be difficult to weld due to its high thermal conductivity, but TIG welding’s precise heat control helps in minimising distortion and achieving clean welds. Use an AC/DC tig welder to weld Aluminium.

Stainless steel, with its corrosion resistance, requires a method like TIG welding that produces high-quality welds with no need for additional cleanup.

Magnesium, copper, brass, and bronze all benefit from TIG welding’s ability to create strong, durable connections while maintaining the integrity of these soft metals.

What Types of Joints Can Be Made with TIG Welding?

TIG welding is highly versatile and can be used to create various types of joints, including those with circular gaps, making it ideal for welding pipes and performing welds in different positions such as vertical, horizontal, and overhead.

The joints that can be made using TIG welding include butt joints, lap joints, corner joints, and T-joints, each serving different purposes in various applications. Butt joints are commonly used for joining two pieces at their ends, while lap joints overlap two materials for a strong connection. Corner joints are ideal for welding perpendicular pieces, and T-joints are used for connecting pieces at right angles. These joints find applications in industries such as aerospace, automotive, and construction.

Welding in vertical, horizontal, and overhead positions requires specific techniques like adjusting the heat input, travel speed, and angle of the torch to ensure proper fusion and penetration. Challenges in welding in different positions include gravity affecting the molten metal flow, potential distortion of the workpiece, and accessibility limitations.

What Are the Advantages of TIG Welding?

One of the main advantages of TIG welding is its exceptional control and precision, which results in minimal spatter and high-quality, aesthetically pleasing welds with minimal finishing required.

This level of control allows welders to work on intricate projects such as fine art sculptures, jewellery making, or delicate automotive components with ease. The precision of TIG welding also makes it ideal for applications where clean, precise welds are essential, such as in aerospace, food industry equipment, or medical devices. The aesthetic quality achieved through TIG welding is highly valued in industries where appearance matters, like architectural metalwork or custom furniture fabrication.

What Are the Disadvantages of TIG Welding?

Despite its many advantages, TIG welding has some disadvantages, including higher costs, slower welding speeds, and the need for a high level of skill and specialised equipment.

In certain situations, these drawbacks can outweigh the benefits of TIG welding. For instance, the higher initial investment required for the specialised equipment and training may not be feasible for smaller welding projects or hobbyists. The slower process of TIG welding can also be a limitation when dealing with time-sensitive tasks or large-scale production where efficiency is crucial. Another challenge arises when working with thicker materials, as TIG welding may not be as efficient or cost-effective compared to other welding methods better suited for such applications.

What Are the Steps to TIG Welding?

The TIG welding process involves several critical steps, starting with the preparation of materials and equipment setup, followed by the actual welding and finishing stages to ensure a high-quality result.

1. Prepare the Materials

Proper preparation of the materials is crucial in TIG welding, including cleaning the base metals thoroughly and fitting them correctly to ensure a strong weld.

This initial stage of material preparation plays a significant role in the overall quality and longevity of the weld. Cleaning the base metals removes any contaminants like dirt, oils, or oxides that can interfere with the welding process and compromise the integrity of the joint.

Fitting the materials properly ensures that there are no gaps or misalignments, which could weaken the weld and lead to potential defects. By taking the time to clean and fit the base metals accurately, welders can create strong and durable welds that meet industry standards and requirements.

2. Set Up the TIG Welder

Setting up the TIG welder involves configuring the TIG welding machines, selecting the appropriate electrodes, and adjusting the gas flow and other settings to match the requirements of the specific welding project.

To start, ensure you have the necessary safety gear like welding gloves and a welding helmet.

- Next, choose the right tungsten electrode based on the material being welded. The electrode diameter, type, and tip shape all play a role in the welding process.

- Then, set up the gas flow rate according to the manufacturer’s recommendations, typically using argon as the shielding gas.

- Adjust the machine settings such as amperage and arc length for the specific thickness of the metal being welded.

Proper setup is crucial for producing strong, clean welds.

3. Start the Welding Process

Starting the TIG welding process involves striking an arc, maintaining the correct torch angle, and carefully feeding the filler rod into the weld pool while controlling the travel speed and arc length. When striking the arc, it is crucial to have the perfect balance of pressure on the pedal to control the heat input onto the workpiece. This helps in maintaining a stable arc with minimal disturbance. Proper torch angle ensures the heat is distributed evenly across the weld joint, preventing defects like undercut or lack of fusion.

4. Finish and Clean Up

After completing the welding process, finishing and clean-up involve removing any spatter, inspecting the weld for quality, and polishing the weld surface as needed.

To begin the clean-up process, it is crucial to carefully inspect the weld for any imperfections or defects that may impact its strength and durability. This includes checking for cracks, porosity, or incomplete fusion. If any issues are detected, they should be addressed promptly before proceeding further.

Next, remove any spatter that has accumulated on the weld using a wire brush or grinder. This will ensure a smooth and clean surface for the final polishing stage. To achieve a professional finish, polish the weld surface using a polishing wheel or abrasive pad to remove any remaining rough edges and enhance the overall appearance.

What Safety Precautions Should You Take?

When performing TIG welding, it is essential to follow safety precautions, including:

- wearing protective gear,

- working in a well-ventilated area,

- being aware of electrical hazards,

- having a fire extinguisher nearby

to ensure a safe working environment.

1. Wear Protective Gear

Wearing protective gear such as gloves, a welding helmet, and flame-resistant clothing is essential to ensure safety while performing TIG welding.

Gloves are crucial in TIG welding as they protect your hands from heat, sparks, and potential burns. Opt for gloves made of high-quality leather or cowhide with added padding on the palms for extra comfort.

In terms of helmets, choose an auto-darkening helmet with a shade range suited for TIG welding to shield your eyes from the intense light and harmful radiation.

Wearing flame-resistant clothing made of materials like cotton or leather can prevent severe burns in case of any accidents during the welding process.

2. Work in a Well-Ventilated Area

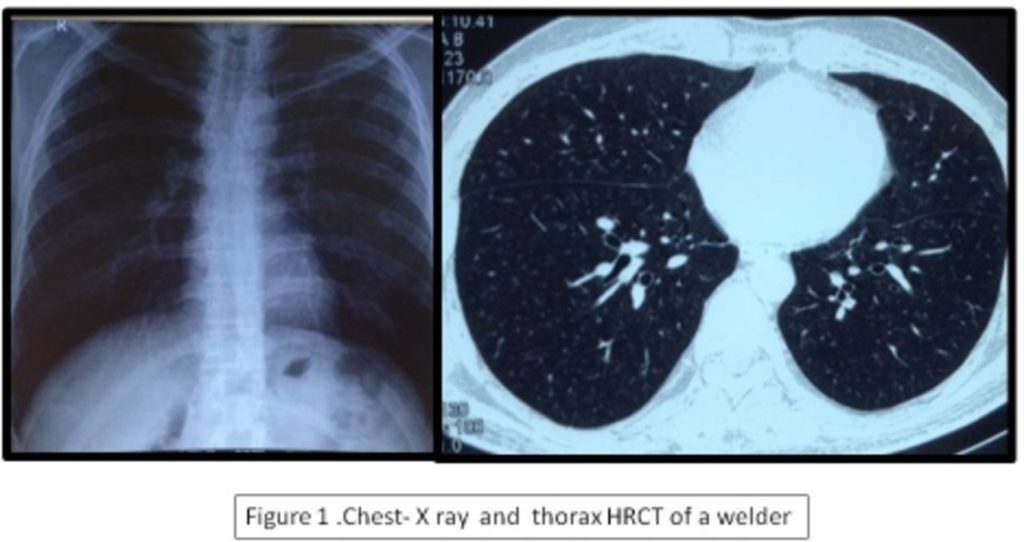

Ensuring proper ventilation in the work area is vital when performing TIG welding to prevent the accumulation of harmful fumes and gases.

Without adequate ventilation, the fumes produced during TIG welding, which contain substances like manganese, chromium, and nickel, can pose serious health risks to individuals exposed to them. Prolonged inhalation of these fumes can lead to respiratory issues, dizziness, and even more severe conditions.

To counter these risks, welders can implement ventilation systems such as local exhaust ventilation to effectively capture and remove welding fumes directly at the source. General ventilation, through the use of fans or natural airflow, can also help disperse fumes in larger workspaces, reducing the concentration of harmful contaminants.

3. Be Aware of Electrical Hazards

TIG welding involves the use of high-voltage equipment, so it is crucial to be aware of electrical hazards and take appropriate precautions to ensure safety.

- When working with TIG welding, one must be diligent in equipment maintenance to prevent electrical malfunctions. Regular inspections of cables, connectors, and power sources are essential to identify and rectify any potential issues.

- Proper grounding is another key aspect to minimise the risk of electric shock. Ensuring that the welding machine is properly grounded can prevent dangerous stray currents and reduce the likelihood of electrical accidents.

Safe handling practices, such as wearing insulated gloves and avoiding contact with wet surfaces, play a significant role in mitigating electrical hazards during TIG welding operations.

4. Have a Fire Extinguisher Nearby

Having a fire extinguisher nearby is a critical safety precaution when performing TIG welding to quickly address any accidental fires that may occur.

In case of a fire during TIG welding, prompt and effective action is essential to prevent a small spark from turning into a dangerous situation. Different types of fires require specific extinguishing agents; for welding environments, it is crucial to have Class D fire extinguishers designed for combating metal fires. Proper placement of fire extinguishers near workstations and maintenance checks to ensure they are fully charged and operational are vital components of fire safety protocols in welding shops. Being proactive in fire prevention measures can greatly reduce the risk of workplace accidents and injuries.

Frequently Asked Questions

What is a TIG welder and how does it work?

A TIG welder is a type of welding machine that uses a tungsten electrode to create an arc that melts the metal and fuses it together. The process also uses a shielding gas to protect the weld from contamination. The welder operates by sending a high-frequency current through the electrode, creating an arc between the electrode and the workpiece.

What materials can be welded using a TIG welder?

TIG welding is commonly used for welding stainless steel, aluminium, and other non-ferrous metals. It is also possible to weld ferrous metals, but it requires a different type of electrode and gas.

What are the advantages of TIG welding?

TIG welding produces high-quality, clean welds with minimal smoke and spatter. It is a precise welding process, making it ideal for welding thin or delicate materials. TIG welding also allows for better control over heat input, resulting in minimal distortion and warping of the workpiece.

When is TIG welding the best choice?

TIG welding is commonly used in applications that require high-quality, precise welds, such as in the aerospace and automotive industries. It is also a popular choice for welding artistic and decorative pieces, as well as for welding thin materials such as sheet metal.

What safety precautions should be taken when TIG welding?

As with any welding process, it is important to wear proper protective gear, including a welding helmet, gloves, and apron. It is also essential to work in a well-ventilated area and to have a fire extinguisher nearby in case of an emergency.

Can TIG welding be automated?

Yes, TIG welding can be automated using specialised robotic systems. This is often used in large-scale production environments to increase efficiency and consistency in the welding process.

Where can I buy a tig welder?

Norsemen Safety & Welder’s Choice provide tig welders and tig welding accessories to the UK and Ireland. Give us a call to discuss your tig welding requirements.