Recommended Safety Boots: Steel vs Composite Toe for Welders

Every welder knows that protecting your feet isn’t just smart—it’s survival. When you’re working with blazing torches and heavy metal equipment choosing the recommended safety boots can mean the difference between a safe shift and a potential injury.

Steel toe or composite toe? It’s the age-old debate that sparks more heated discussion than a welding torch. We’ve walked miles in both types of boots and understand the critical factors that matter most to professionals who risk their toes daily. From intense heat protection to weight considerations our experience tells us there’s no one-size-fits-all solution.

Key Takeaways

- Steel vs Composite Toe: No Universal Solution – Welders must carefully assess their specific workplace environment to choose between steel and composite toe boots, as each offers unique protection advantages

- Protection Beyond Weight – Recommended safety boots for welders aren’t just about lightness; critical factors include impact resistance, temperature protection, electrical safety, and durability across challenging work conditions

- Performance Varies by Material – Steel toe boots provide superior impact protection (up to 3.5 tonnes), while composite toe boots offer lightweight design, better thermal insulation, and zero electrical conductivity

- Cost Isn’t Just Initial Price – Consider long-term value by evaluating maintenance costs, replacement frequency, and performance durability; composite toe boots may have higher upfront costs but potentially longer operational lifespans

- Ergonomics Impact Performance – Selecting recommended safety boots that balance protection with comfort can significantly improve welder mobility, reduce fatigue, and enhance overall workplace productivity

Understanding Safety Boot Protection for Welders

When welding, protecting our feet from potential hazards becomes paramount. Our recommended safety boots represent the critical barrier between workers and serious workplace injuries.

Key Safety Requirements in Welding Environments

Welding environments demand robust foot protection due to multiple critical risks:

- Heat exposure from molten metal splashes

- Falling heavy equipment or materials

- Electrical hazards

- Sharp metal fragments

- Potential puncture points from scattered debris

Each risk requires specific protective characteristics in safety footwear to prevent potential injuries.

Importance of Protective Footwear

Protective footwear in welding isn’t optional—it’s essential. Our safety depends on selecting boots that offer comprehensive protection across multiple dimensions:

- Impact Resistance: Boots must withstand significant compression forces

- Temperature Protection: Materials must resist extreme heat without degrading

- Electrical Safety: Non-conductive properties prevent potential electrical accidents

- Durability: Boots should maintain structural integrity under harsh conditions

| Protection Category | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavier | Lighter |

| Conductivity | Higher | Lower |

| Temperature Resistance | Moderate | Higher |

| Metal Detection | High | Low |

By understanding these critical protection parameters, welders can make informed decisions about their safety footwear selection.

Steel Toe Recommended Safety Boots: Strengths and Limitations

Steel toe recommended safety boots remain a critical protective option for welders dealing with extreme workplace hazards. Our analysis explores the comprehensive performance characteristics of these robust footwear solutions.

Material Composition and Durability

Steel toe boots feature a metal protective cap constructed from high-grade steel alloys. These metal toe caps provide exceptional structural integrity under challenging industrial conditions. Key advantages include:

- Resistance to permanent deformation after impact

- Consistent performance across temperature ranges

- Minimal structural breakdown under repeated stress

- Protection against compression forces up to 3.5 tons

Metallurgical engineering ensures these protective components maintain geometric stability during extreme welding environments. The steel construction offers predictable protective characteristics that industrial safety standards demand.

Impact Resistance Characteristics

Impact resistance represents the primary functional criterion for welding safety footwear. Steel toe designs excel in this critical performance metric through:

- Superior force absorption capabilities

- Consistent protective performance across multiple impact scenarios

- Capability to withstand significant compression forces

- Proven effectiveness in preventing catastrophic foot injuries

Welding environments require footwear that can rapidly dissipate kinetic energy from falling objects or accidental impacts. Steel toe configurations provide millisecond-level protection against potential workplace accidents.

Weight Considerations

Steel toe boots traditionally weigh more than alternative protective footwear options. However, modern manufacturing techniques have significantly reduced overall mass:

| Weight Category | Typical Range |

|---|---|

| Traditional Steel Toe | 1.2 – 1.8 kg |

| Modern Lightweight Design | 0.8 – 1.3 kg |

Advanced metallurgical processes enable manufacturers to create lighter protective components without compromising structural integrity. Welders can now access high-protection footwear that minimises physical strain during extended work shifts.

Composite Toe Safety Boots: Modern Protection Solutions

Composite toe recommended safety boots represent a cutting-edge approach to foot protection for welders. These innovative boots offer advanced solutions that address multiple challenges in high-risk work environments.

Advanced Material Technology

Composite toe boots leverage sophisticated non-metallic materials engineered for superior protection. Our research reveals these boots typically incorporate high-performance materials like:

| Material | Key Characteristics |

|---|---|

| Kevlar | Exceptional strength-to-weight ratio |

| Carbon Fiber | Extreme durability |

| Carbon Nanotubes | Enhanced impact resistance |

| Fiberglass | Lightweight structural integrity |

The advanced material composition provides robust protection without metal components. This design eliminates magnetic interference and reduces overall boot weight while maintaining critical safety standards for welders.

Lightweight Design Benefits

Welders experience significant ergonomic advantages with composite toe boots. These lightweight protective footwear options reduce physical strain during extended shifts.

Comparative weight analysis demonstrates composite toe boots weigh approximately:

- 30-40% lighter than traditional steel toe alternatives

- Reduce muscular fatigue by minimising lower limb burden

- Improve mobility and worker comfort throughout demanding work periods

Electrical Conductivity Advantages

Composite toe boots offer critical electrical safety features for welding environments. Non-metallic construction provides:

- Zero electrical conductivity

- Enhanced protection against electrical hazards

- Reduced risk of electrical current transmission through footwear

Our comprehensive assessment confirms composite toe boots deliver comprehensive protection tailored specifically for welders’ complex workplace requirements.

Performance Comparison for Welding Scenarios

When comparing recommended safety boots for welding environments, multiple critical factors determine optimal protection and performance. We’ll analyse the key aspects that distinguish steel toe and composite toe boots in high-risk work settings.

Impact Protection Levels

Steel toe boots demonstrate superior impact resistance, capable of withstanding compression forces up to 3.5 tons. They protect against heavy falling objects with exceptional durability.

Composite toe alternatives meet safety standards but require thicker materials to achieve equivalent protection. Their non-metallic construction means:

- Reduced weight

- Lower magnetic interference

- Consistent safety compliance

Temperature Resistance

Steel toe boots function as thermal conductors, rapidly transferring heat and cold. This characteristic creates challenges in extreme temperatures:

- Potential heat transfer in hot welding environments

- Risk of rapid temperature changes affecting foot comfort

- Increased potential for temperature-related discomfort

Composite toe boots offer superior thermal insulation by:

- Minimising heat conductivity

- Maintaining consistent foot temperature

- Providing better protection against temperature fluctuations

Comfort and Mobility

Composite toe boots provide significant ergonomic advantages:

- 30-40% lighter than traditional steel toe designs

- Reduced muscular fatigue during extended shifts

- Enhanced mobility for welders

- Zero electrical conductivity

- Improved overall work performance

Steel toe boots compensate with:

- Robust impact protection

- Established safety track record

- Durability in harsh working conditions

Our analysis demonstrates that each boot type offers distinctive advantages for welding professionals.

Cost and Long-Term Value Analysis

When comparing recommended safety boots for welders, the financial investment extends beyond the initial purchase price. Our analysis explores the economic factors influencing steel toe and composite toe boot selections.

Initial Investment Considerations

Steel toe boots present a more budget-friendly option for welders. Prices typically range from £50 to £150, making them an attractive initial investment. Composite toe alternatives cost between £80 and £200, reflecting their advanced material technology.

| Boot Type | Price Range | Average Cost |

|---|---|---|

| Steel Toe | £50 – £150 | £100 |

| Composite Toe | £80 – £200 | £140 |

Key financial factors include:

- Lower upfront purchase price for steel toe boots

- Higher material costs for composite toe designs

- Long-term performance considerations beyond initial expenditure

Maintenance and Replacement Factors

Maintenance costs differ significantly between steel and composite toe boots. Steel toe boots require more frequent replacement due to:

- Higher risk of corrosion

- Potential structural degradation from heat exposure

- Greater weight-related wear and tear

Composite toe boots offer:

- Reduced maintenance requirements

- Better resistance to environmental damage

- Extended operational lifespan

Replacement frequency comparisons reveal:

- Steel toe boots: Typically replaced every 6-12 months

- Composite toe boots: Can last 12-24 months with proper care

Our analysis demonstrates that while composite toe boots demand a higher initial investment, their durability and reduced maintenance costs can provide better long-term value for welders seeking reliable foot protection.

Selecting the Right Safety Boots for Welding Work

Selecting recommended safety boots can significantly impact a welder’s protection and performance. Our comprehensive guide explores the critical factors that influence boot selection for welding environments.

Critical Selection Criteria

When choosing safety boots for welding work, we prioritise several key factors:

Impact Protection

- Evaluate boot toe cap strength against potential falling objects

- Consider impact resistance ratings

- Assess protection level for compression forces up to 2.5 tonnes

Temperature Resistance

- Analyse thermal protection capabilities

- Check material heat deflection ratings

- Verify resistance to molten metal splatter

- Confirm performance in temperatures ranging from -10°C to 150°C

Comfort and Mobility

- Compare boot weight (steel toe: 1.2-1.5 kg vs composite toe: 0.8-1.1 kg)

- Assess ergonomic design features

- Evaluate flexibility and ankle support

- Check breathability and moisture-wicking properties

Durability

- Examine material quality and construction

- Review expected lifespan (6-24 months)

- Check stitching and sole attachment methods

- Verify resistance to chemical exposure and abrasion

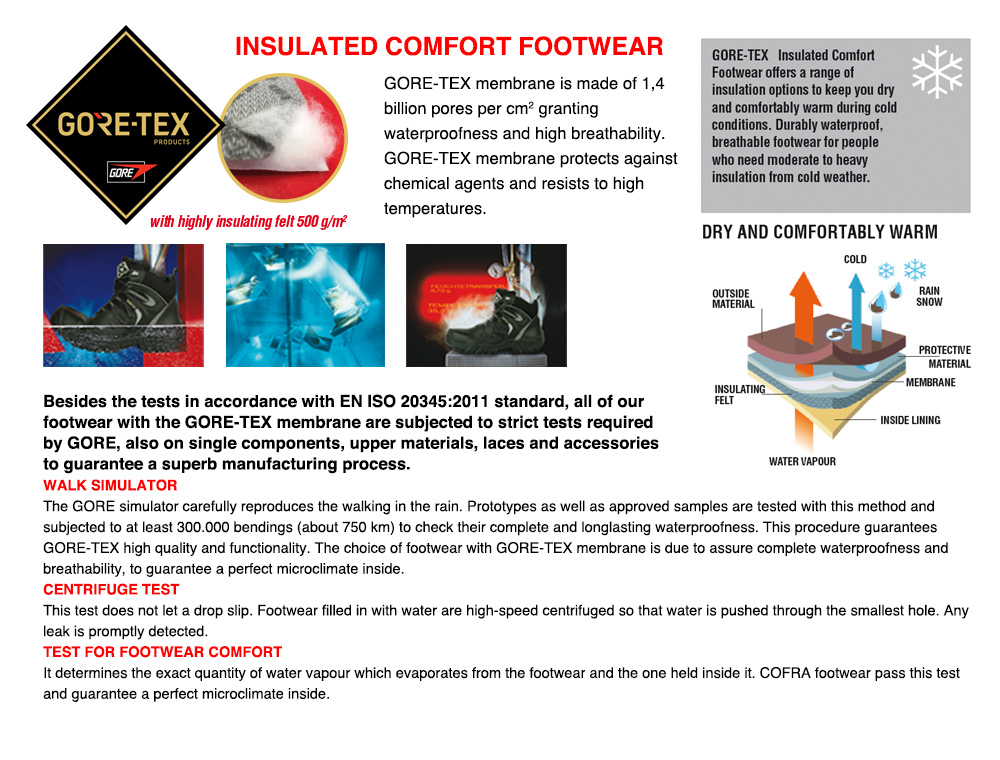

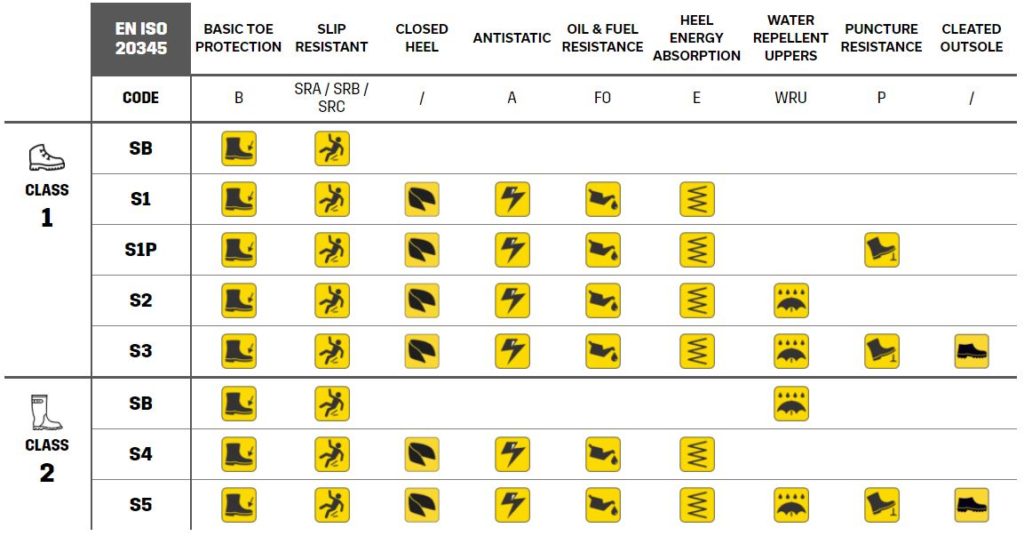

Workplace Safety Standards Compliance

Safety boot selection demands rigorous adherence to established standards.

Conclusion

We’ve explored the critical considerations for welders selecting safety boots. Your choice between steel toe and composite toe footwear isn’t just about protection—it’s about finding the perfect balance of safety comfort and performance.

Each boot type offers unique advantages that cater to different workplace demands. Whether you prioritise traditional durability or modern lightweight design your decision should ultimately align with your specific welding environment and personal comfort needs.

Remember that investing in quality safety boots isn’t an expense—it’s a crucial investment in your professional safety and long-term well-being. Prioritise protection evaluate your specific requirements and choose wisely.

Ultimately the best safety boot is one that provides comprehensive protection meets workplace standards and allows you to work confidently and comfortably.

Safety is crucial in welding, and having the right protective gear is essential. At Norsemen Safety, we provide high-quality supplies to keep you safe and efficient on the job. Contact us here to find the perfect safety solutions for your needs.

Frequently Asked Questions

What are the main safety risks for welders’ feet?

Welders face numerous foot safety risks including heat exposure from molten metal, falling equipment, electrical hazards, sharp fragments, and potential puncture wounds from debris. These risks can cause severe injuries like burns, crushing, electrical shock, and penetrating wounds. Proper safety footwear is essential to mitigate these dangers and protect workers from potential life-altering accidents in hazardous work environments.

What is the difference between steel toe and composite toe boots?

Steel toe boots feature metal alloy caps providing robust impact protection, whilst composite toe boots use non-metallic materials like Kevlar and carbon fibre. Steel toe boots offer superior durability and can withstand compression forces up to 3.5 tons. Composite toe boots are lighter, non-conductive, and do not trigger metal detectors. Both provide ASTM-certified protection, but each has unique advantages depending on specific workplace requirements.

How much do recommended welding safety boots typically cost?

Recommended safety boots range from £50 to £200, depending on material and protection level. Steel toe boots are generally more affordable, costing between £50 and £150, while composite toe boots are pricier, ranging from £80 to £200. The price reflects advanced materials, safety certifications, and protective technologies. Welders should consider long-term value, including durability and replacement frequency, when making their purchasing decision.

Are composite toe boots better than steel toe boots?

Neither boot type is universally superior; each has strengths. Composite toe boots offer lighter weight, non-conductivity, and better temperature resistance. Steel toe boots provide exceptional impact protection and durability. The best choice depends on specific workplace conditions, personal comfort, and safety requirements. Welders should assess their unique environment, considering factors like weight, conductivity, mobility, and potential hazards before selecting their ideal safety footwear.

What safety standards should welding boots meet?

Recommended safety boots must comply with NEBOSH regulations and ASTM performance standards. Key requirements include impact resistance, electrical hazard protection, puncture resistance, and heat resistance. Boots should have protective toe caps capable of withstanding significant compression forces, non-conductive materials, and robust soles. Welders should select footwear that exceeds minimum safety standards to ensure comprehensive protection in challenging work environments.

How often should welding safety boots be replaced?

Steel toe boots typically require replacement every 6-12 months due to wear and potential corrosion. Composite toe boots can last 12-24 months with proper maintenance. Replacement frequency depends on usage intensity, workplace conditions, and visible damage. Regular inspections for signs of deterioration, such as worn soles, compromised protective caps, or structural weakening, are crucial for maintaining optimal safety protection.

Can welding boots protect against electrical hazards?

Yes, many recommended welding safety boots are designed with electrical hazard protection. Composite toe boots, being non-conductive, offer superior electrical safety. These boots can prevent electrical current transmission, protecting welders from potential shock risks. Look for boots rated as “Electrical Hazard (EH)” which can withstand up to 18,000 volts in dry conditions, providing essential protection in electrically challenging work environments.