MIG Welding 101: Master the Art of Metal Joining Like a Pro

Ever watched a skilled welder fuse metal like it’s child’s play? That’s the magic of MIG welding! We’re diving into this popular welding technique that’s as versatile as a Swiss Army knife in the world of metal fabrication.

MIG welding, short for Metal Inert Gas welding, is the go-to method for many DIY enthusiasts and pros alike. It’s like using a hot glue gun, but for metal! Remember that time your buddy tried to weld and ended up with a pile of molten mess? We’ve all been there. But with MIG welding, even beginners can create strong, clean welds.

Key Takeaways

- MIG welding uses a wire electrode and shielding gas to join metals, offering speed, clean welds, and versatility across various applications.

- Essential MIG welding equipment includes the welder, shielding gas, and wire feed system, each playing a crucial role in creating strong, quality welds.

- Proper techniques, including correct welder setup, gun positioning, and mastering common welding patterns, are vital for achieving high-quality MIG welds.

- Safety is paramount in MIG welding, requiring appropriate personal protective equipment (PPE) and a well-organized, ventilated workspace.

- MIG welding is widely used in automotive, construction, and manufacturing industries, with applications ranging from car frames to structural steel fabrication.

What Is MIG Welding?

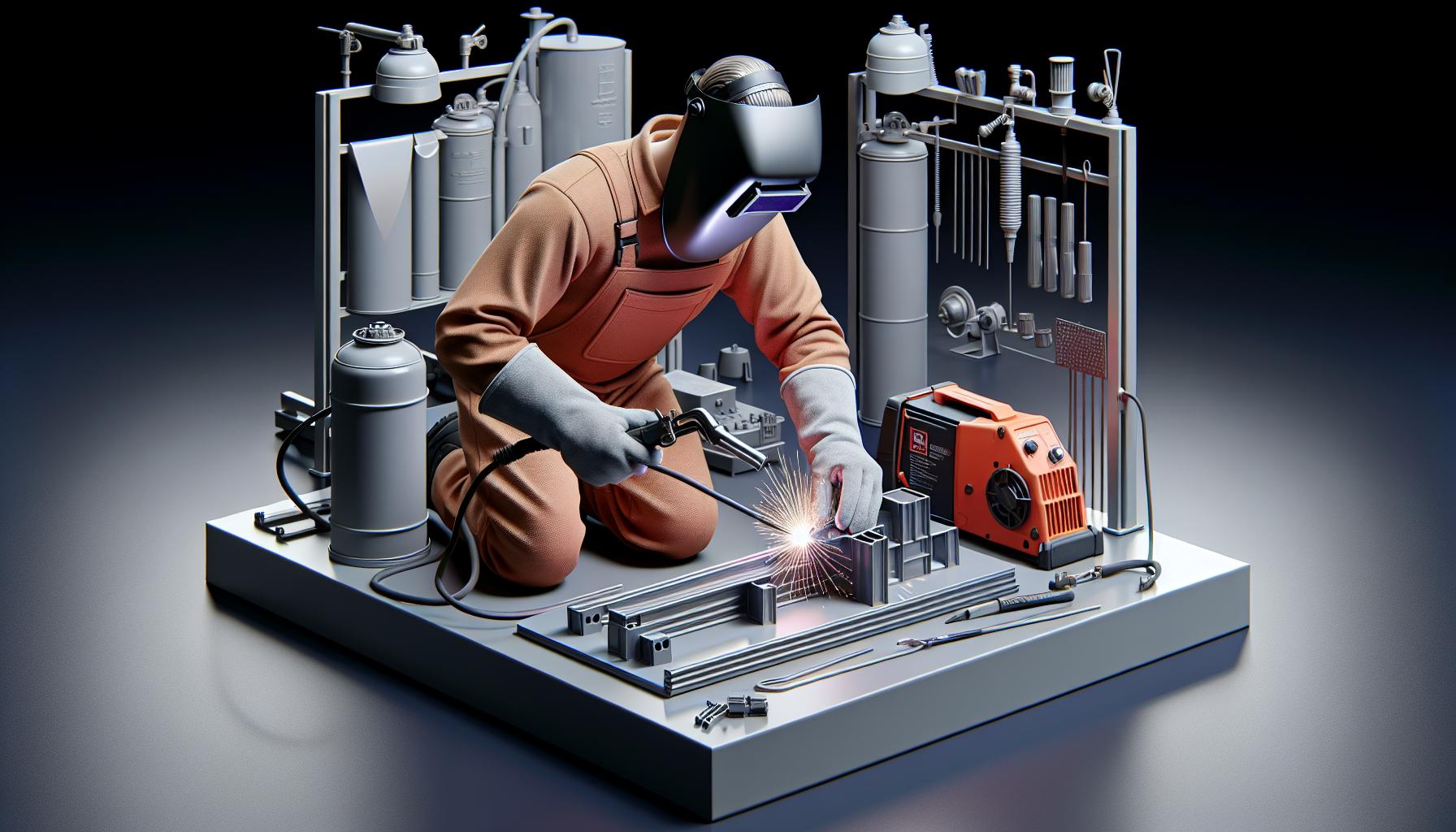

MIG welding, short for Metal Inert Gas welding, is a process that uses a continuously fed wire electrode and shielding gas to join metal pieces. This welding method is known for its efficiency and versatility across various metal fabrication applications.

How MIG Welding Works

MIG welding operates by creating an electric arc between the workpiece and a consumable wire electrode. The wire feeds through a welding gun, melting as it contacts the workpiece. Simultaneously, an inert gas (typically argon or a mix) flows from the gun, shielding the weld pool from atmospheric contamination.

The process involves:

- Setting up the welding machine with the correct wire and gas

- Adjusting voltage and wire feed speed

- Positioning the gun at a 15-30 degree angle to the workpiece

- Pulling the trigger to start the arc and moving along the joint

Ever wondered what it’s like to write with molten metal? That’s essentially what MIG welding feels like!

Advantages of MIG Welding

MIG welding offers several benefits that make it a go-to choice for many welders:

- Speed: It’s faster than many other welding methods

- Clean welds: Minimal slag means less post-weld cleanup

- Versatility: Works on various metal thicknesses and types

- Easy to learn: Beginners can pick up basic techniques quickly

- Precision: Allows for accurate control of the weld bead

Remember that time you tried to glue a broken vase back together? MIG welding is like that, but for metal – and way cooler! You get to play with electricity and molten metal. What’s not to love?

Essential MIG Welding Equipment

MIG welding requires specific tools to create strong, clean welds. Let’s explore the key equipment needed for successful MIG welding projects.

MIG Welders

MIG welders are the heart of the welding process. These machines come in various sizes and power outputs, from compact units for home use to industrial-grade models. Think of a MIG welder as your metal-melting sidekick – it’s always ready to jump into action! When choosing a welder, consider factors like:

- Amperage range

- Duty cycle

- Input voltage requirements

- Portability

Have you ever wondered how these machines can turn a simple wire into a molten metal masterpiece? It’s like having a miniature lightning bolt at your fingertips!

Shielding Gas

Shielding gas is the invisible hero of MIG welding. It protects the weld pool from atmospheric contamination, ensuring a clean and strong weld. Common shielding gases include:

- 100% CO2

- Argon/CO2 mix

- Tri-mix (argon, CO2, and helium)

Choosing the right gas is like picking the perfect dance partner for your metal – it’s got to match the moves! Remember that time we accidentally used the wrong gas and our welds looked like a toddler’s crayon scribbles? Yeah, let’s not repeat that!

Wire Feed System

The wire feed system is the steady hand that guides your welding wire. It consists of:

- Wire spool

- Drive rollers

- Gun and cable assembly

MIG Welding Techniques

MIG welding techniques are essential for creating strong, clean welds. We’ll explore the key aspects of setting up your welder, maintaining proper welding positions, and mastering common welding patterns.

Setting Up Your Welder

Setting up your MIG welder correctly is crucial for achieving high-quality welds. Start by selecting the appropriate wire diameter and type for your project. Adjust the wire feed speed and voltage settings based on the material thickness and type. Remember to set the gas flow rate to provide adequate shielding for your weld pool. It’s like tuning an instrument – get it right, and you’ll create beautiful metal music!

Proper Welding Position

Maintaining the right welding position is key to producing consistent, high-quality welds. Hold the welding gun at a 10-15 degree push angle and keep a consistent travel speed. Maintain a 1/4 to 3/8 inch stick-out (the distance between the contact tip and the workpiece). Think of it as a dance – you’re leading, and the metal follows your smooth, steady movements.

Common Welding Patterns

Mastering common welding patterns improves weld quality and appearance. The three main patterns are:

- Straight line: Move the gun in a straight line along the joint.

- Weave: Move the gun in a side-to-side motion while progressing along the joint.

- Circle: Create small circles as you move along the joint.

Each pattern has its place, depending on the joint type and material thickness. It’s like choosing the right dance steps for different songs – you’ll want to master them all!

Ever tried to write your name in cursive with molten metal? That’s essentially what you’re doing with these patterns. Practice makes perfect, so don’t be discouraged if your first attempts look more like abstract art than neat welds.

MIG Welding Safety Precautions

Safety is paramount in MIG welding. Proper precautions protect welders from potential hazards and create a secure work environment. Let’s explore the essential safety measures every MIG welder should know.

Personal Protective Equipment

Gearing up for MIG welding is like suiting up for a superhero mission. Our first line of defense is personal protective equipment (PPE). Here’s what we need:

- Welding helmet: A must-have to shield our eyes and face from intense light and sparks. Auto-darkening helmets are a game-changer, adjusting automatically to protect our vision.

- Welding gloves: These heavy-duty gloves safeguard our hands from heat and spatter. They’re like oven mitts on steroids!

- Fire-resistant clothing: Long-sleeved shirts and pants made of flame-resistant materials keep us safe from sparks and UV radiation.

- Steel-toed boots: Our feet need protection too. Steel-toed boots guard against falling objects and hot metal.

- Respirator: This crucial piece of equipment filters out harmful fumes and particulates. Think of it as a gas mask for welders.

Remember, skimping on PPE is like going into battle without armor. It’s not worth the risk!

Workspace Considerations

Creating a safe welding workspace is key to preventing accidents. Here’s how we set up our welding area:

- Ventilation: Good airflow is crucial. We set up fans or use a ventilation system to remove welding fumes. It’s like creating a fresh breeze in our workspace.

- Fire prevention: We keep flammable materials far from our welding area. A fire extinguisher is always within reach, just in case things get too hot to handle.

- Clutter-free zone: We keep our workspace tidy and organized. Tripping over tools while holding a welding gun is a recipe for disaster!

- Electrical safety: We check all electrical connections and equipment regularly. Faulty wiring can turn our welding adventure into a shocking experience.

- Proper lighting: Good lighting helps us see what we’re doing. We don’t want to be fumbling around in the dark with molten metal!

Have you ever thought about how your workspace affects your welding quality? A clean, organized area not only keeps us safe but also improves our work.

Here’s a funny tidbit: A welder once told us he used to keep his sandwich next to his welding area. One day, he accidentally grabbed his welding rod instead of his lunch! Needless to say, he learned his lesson about keeping food away from the workspace.

Applications of MIG Welding

MIG welding’s versatility makes it a go-to choice for various industries. From joining thin sheet metal to fabricating heavy-duty structures, this welding process adapts to numerous applications.

Automotive Industry

In the automotive world, MIG welding is the backbone of vehicle production. It’s used to create everything from car frames to exhaust systems. Remember that rusty muffler you replaced last year? Chances are, MIG welding played a part in crafting its replacement. This technique’s precision allows for strong, clean welds on thin auto body panels without warping the metal. Ever wondered how those sleek sports cars maintain their smooth lines? MIG welding’s the secret sauce!

Funny story: A friend once tried to MIG weld a custom spoiler onto his car. He ended up with what looked like a melted candy bar stuck to his trunk. Lesson learned: Leave the auto body mods to the pros!

Construction and Manufacturing

MIG welding is the unsung hero of the construction and manufacturing sectors. It’s used to fabricate structural steel for buildings, bridges, and even those massive cranes that dot city skylines. In manufacturing, MIG welding helps create everything from industrial equipment to home appliances. Ever seen those massive wind turbines? MIG welding plays a crucial role in their construction.

Here’s a question for you: What’s the last thing you used today that might have been MIG welded? Your office chair? The elevator you rode? The possibilities are endless!

MIG welding’s speed and efficiency make it ideal for high-volume production. It’s like the fast food of the welding world – quick, consistent, and always ready to serve. But don’t let that fool you; the quality is top-notch when done right.

Troubleshooting Common MIG Welding Issues

Even seasoned welders face challenges with MIG welding. Let’s dive into some common issues and how to fix them. Remember, every welder has been there, so don’t get discouraged!

Wire Feed Problems

Wire feed issues can turn your welding project into a frustrating game of “why won’t this work?” Common culprits include clogged liners, worn drive rolls, or incorrect tension settings. To fix these:

- Clean or replace the liner

- Check drive rolls for wear and replace if necessary

- Adjust wire tension – it should feel like you’re reeling in a medium-sized fish

Ever had your wire bunch up like a tangled ball of yarn? We’ve all been there! One welder we know nicknamed his bunched-up wire “the metal spaghetti monster.” Remember, patience is key when untangling these messes.

Poor Weld Quality

Struggling with ugly welds? Don’t worry, we’ve got your back. Poor weld quality often stems from incorrect settings, contaminated materials, or improper technique. Here’s how to tackle these issues:

- Adjust your voltage and wire feed speed

- Clean your base metal thoroughly

- Practice your gun angle and travel speed

Think of welding like cooking – too much heat burns your food, too little leaves it raw. Finding the right balance takes practice, but once you get it, you’ll be serving up perfect welds every time!

Advancing Your MIG Welding Skills

Improving MIG welding skills requires practice and dedication. We’ll explore projects for beginners and advanced techniques to help you become a better welder.

Practice Projects for Beginners

Beginners can start with simple projects to hone their MIG welding skills:

- Welding scrap metal: Practice creating straight beads on flat pieces of scrap metal.

- Metal box: Construct a small box by welding four sides and a bottom.

- Coat rack: Make a functional coat rack using metal pipes and plates.

- Garden tools holder: Create a storage rack for garden tools using angle iron.

- Welding cart: Build a mobile cart to store your welding equipment.

These projects allow you to practice different joint types and positions. Remember, welding is like learning to ride a bike – the more you practice, the better you’ll get!

Advanced MIG Welding Techniques

Ready to level up your MIG welding game? Try these advanced techniques:

- Pulse welding: This technique alternates between high and low current, reducing heat input and distortion.

- Push-pull welding: Ideal for aluminum, this method uses a special gun to push and pull the wire through the liner.

- Out-of-position welding: Master welding in vertical and overhead positions for challenging projects.

- Thin material welding: Learn to weld materials as thin as 24 gauge without burn-through.

- Multi-pass welding: Create stronger welds on thick materials by laying multiple passes.

Think of these techniques as adding new dance moves to your welding repertoire. They might feel awkward at first, but with practice, you’ll be grooving like a pro!

Have you ever tried welding upside down? It’s like trying to write your name while doing a handstand – tricky, but not impossible! We once knew a welder who accidentally welded his zipper while attempting an overhead weld. Let’s just say he learned the importance of proper positioning the hard way!

Conclusion

MIG welding stands as a versatile and accessible technique in the world of metal fabrication. We’ve explored its fundamental principles applications and essential equipment. From safety considerations to troubleshooting tips we’ve covered the key aspects of this popular welding method. Whether you’re a DIY enthusiast or a professional welder MIG welding offers a reliable way to join metals with efficiency and precision. As with any skill mastery comes with practice and dedication. So grab your welder don your safety gear and start your journey into the exciting world of MIG welding. You’ll soon discover why it’s become a go-to method for welders across industries.

Frequently Asked Questions

What is MIG welding?

MIG welding, or Metal Inert Gas welding, is a process that uses a continuously fed wire electrode and shielding gas to join metal pieces. It’s known for its efficiency and versatility across various applications, making it popular among both DIY enthusiasts and professionals.

How does MIG welding work?

MIG welding creates an electric arc between the workpiece and a consumable wire electrode. An inert gas shields the weld pool from contamination. The process involves setting up the machine, adjusting voltage and wire feed speed, and positioning the gun correctly to create a strong, clean weld.

What are the advantages of MIG welding?

MIG welding offers several benefits: it’s fast, produces clean welds with minimal slag, works on various metal types and thicknesses, is easy for beginners to learn, and allows precise control of the weld bead. Its versatility and efficiency make it a popular choice in many industries.

What equipment is needed for MIG welding?

Essential MIG welding equipment includes a MIG welder, shielding gas, and a wire feed system. The welder is the primary tool, while shielding gas protects the weld pool from contamination. The wire feed system guides the welding wire for optimal results.

How do I choose the right MIG welder?

When selecting a MIG welder, consider factors like amperage range, duty cycle, input voltage requirements, and portability. Think about the types of projects you’ll be working on and choose a welder that matches your needs in terms of power output and features.

What shielding gases are used in MIG welding?

Common shielding gases for MIG welding include 100% CO2 and argon/CO2 mixes. The choice of gas depends on the type of metal being welded and the desired weld characteristics. Selecting the right gas is crucial for successful welding.

What are some basic MIG welding techniques?

Key MIG welding techniques include setting up the welder correctly, maintaining proper gun angle (10-15 degrees), and using appropriate welding patterns like straight line, weave, or circle. Consistent travel speed and practice are essential for creating strong, clean welds.

What safety precautions should I take when MIG welding?

Essential safety measures include wearing proper personal protective equipment (PPE) such as welding helmets, gloves, fire-resistant clothing, steel-toed boots, and respirators. Ensure proper ventilation, maintain a clutter-free workspace, and check electrical safety before welding.

What industries commonly use MIG welding?

MIG welding is widely used in automotive, construction, and manufacturing industries. It’s employed for fabricating car frames, exhaust systems, structural steel, and industrial equipment. Its speed and efficiency make it a popular choice across various sectors.

How can I troubleshoot common MIG welding issues?

To troubleshoot MIG welding problems, check for wire feed issues by cleaning or replacing components and adjusting wire tension. For poor weld quality, adjust settings, clean base metals, and refine your technique. Remember, finding the right balance is key to successful welding.

What are some beginner projects for practicing MIG welding?

Beginners can practice MIG welding on projects like welding scrap metal, constructing a metal box, making a coat rack, creating a garden tools holder, or building a welding cart. These projects help novices develop their skills and gain confidence in welding.

What are some advanced MIG welding techniques?

Advanced MIG welding techniques include pulse welding, push-pull welding, out-of-position welding, thin material welding, and multi-pass welding. These techniques require practice and dedication but can significantly enhance a welder’s skill set and capabilities.