Miller MigMatic 300 MIG Welder Superior arc control technology DISCONTINUED

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Miller MigMatic 300 MIG Welder Superior arc control technology DISCONTINUED

€2,218.59 (ex VAT) €2,662.31(inc VAT)

Miller Migmatic 300 machine has a digital meter, showing the current, voltage or wire feed speed. It features an adjustable run in & burnback, optimising arc starts/stops. With a modern transformer design, excellent starting & stable arc, this Miller MIG Welder is suitable for a range of applications. Miller True Blue 3 Year Warranty

Out of stock

Orders OVER £75 (Excluding VAT)

Orders UNDER £75 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Have a Question? Ask a Specialist

Low Prices

Price match guarantee

Wide range of products available

Always the correct part

In-House Experts.

We know our products

Easy Returns.

Quick & Hassle Free

Miller MigMatic 300 MIG Welder – Discontinued

The Miller Migmatic 300iP is a good alternative to consider.

Why has the Miller Migmatic 300 from Miller Welding been discontinued?

Effective from 1st January 2024, there was a ban on the manufacture and import of transformer-based welders into the UK and EU. This is a significant regulatory change in the welding industry. This ban is part of a broader initiative to enhance energy efficiency and reduce the environmental impact of industrial processes, including welding.

The key aspects of this change stem from EU regulations introduced in January 2021, focusing on the ecodesign requirements of welding equipment. These regulations are aimed at addressing the environmental impact of welding, particularly in terms of energy consumption. Welding is an energy-intensive process, and the regulations estimate that by 2030, the annual final energy consumption directly related to welding equipment could exceed 6 TWh. This consumption is equivalent to around 2.4 million tonnes of CO2. The regulations cover three main areas: energy efficiency, resource efficiency, and information requirements.

Regarding energy efficiency, welding equipment must comply with specific power source efficiency and idle state power consumption limits.

The resource efficiency requirements focus on the availability of spare parts for a minimum of 10 years after the production of the unit. This ensures that the welding equipment remains operable and efficient for a longer period, reducing waste and the need for frequent replacements.

Long-term, adhering to these regulations is expected to bring tangible benefits in terms of energy savings and reduced CO2 emissions. The new ecodesign measures are projected to save an average of 1.09 TWh or 0.27 Mt CO2 equivalent annually by 2030, which is beneficial for both businesses and the environment.

The 2021 EU Ecodesign regulations also made amendments to Regulation 548/2014 on transformer losses, further tightening requirements for load-losses and no-load-losses on energy-related products.

The European Commission estimates that 2.9% of all energy generated in the EU and the UK is wasted through transformer losses, amounting to approximately 93.4 TWh annually. The new design regulations aim to reduce these energy losses, saving on average 16 TWh annually and preventing about 3.7 Mt CO2 from being emitted into the atmosphere.

For businesses and manufacturers, these regulations mean that any new transformers purchased must meet the Tier 2 standard, unless they are bought from existing stock. This change is crucial for ensuring that welding equipment is eco-friendly and compliant with EU regulations.

The ban on transformer-based welders is a significant step towards more sustainable industrial practices, aligning with broader environmental goals set by the EU and UK. For more detailed information on the new regulations and their implications for the welding industry, it’s recommended to refer to the full breakdown of the EU requirements regarding eco-friendly welding equipment, available on the official EU regulation website. If you have any other questions about why the Miller Migmatic 300 has been discontinued, please give us a call.

Miller MigMatic 300 MIG welder a digital meter, showing the current, voltage or wire feed speed. It features an adjustable run in & burnback, optimising arc starts/stops.

This machines includes a 360Amp x 4m torch & regulator & earth lead

Welding parameters can be set using the Manual Mode, this allows for welding on a broader range of applications.

The machine uses an industrial dual gear driven system featuring a reversible drive roll (1.0mm / 1.2mm) & an adjustment knob.

This machine holds a professional drive motor that can work efficiently on most applications.

Its superior arc control technology allows for high quality welding performance on a range of applications.

Burnback controls prevent wire stubbing or wire burnback & also optimise the arc starts & stops.

The spot weld timer allows for consistent spot welds every time.

Looking for information about settings on a mig welder, Miller-Mig-Settings

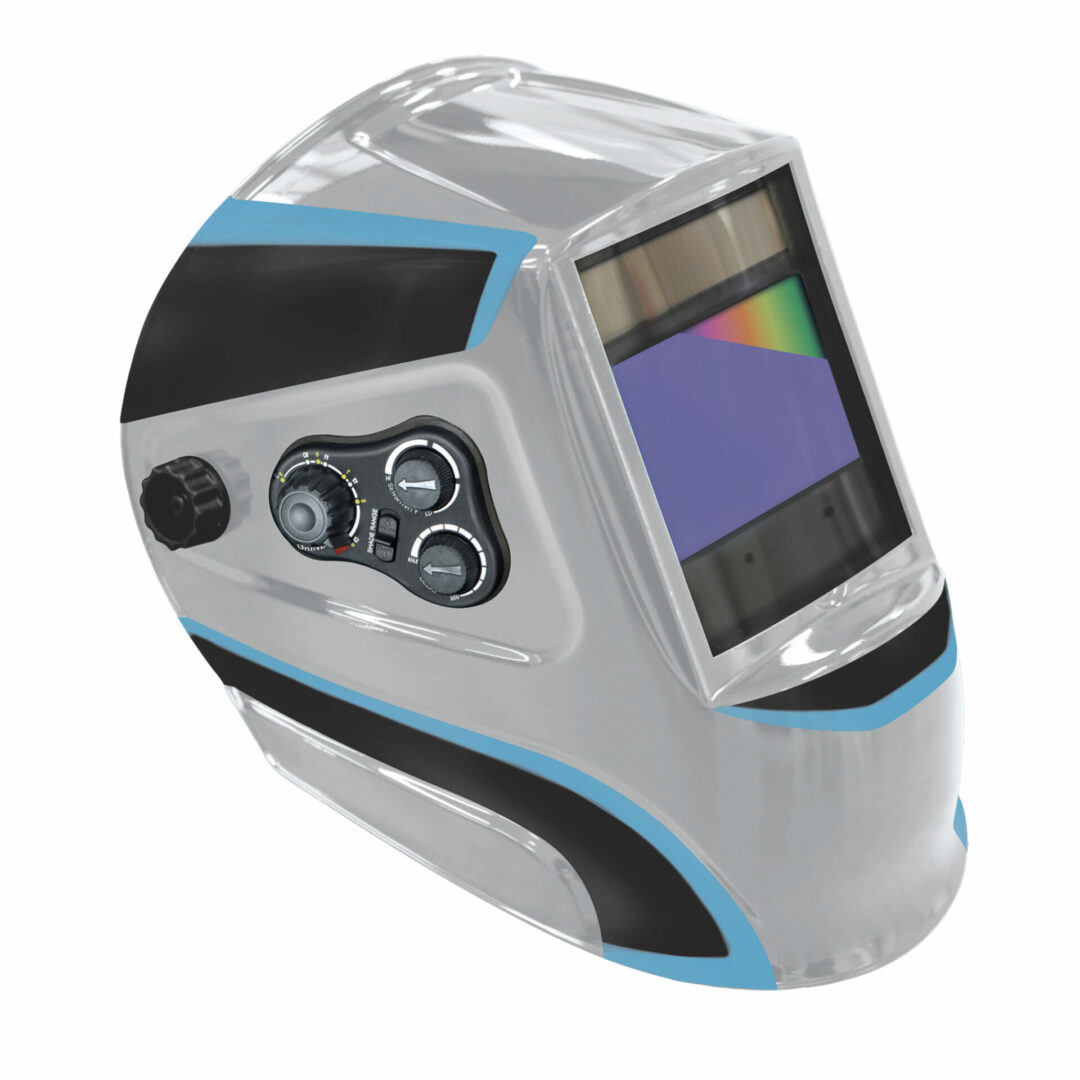

Have a look at the Miller PAPR welding helmet for protection while welding.

Miller spare parts are still available for the Miller Migmatic 300, give us a call on 028 9046 0541 for price and availability.