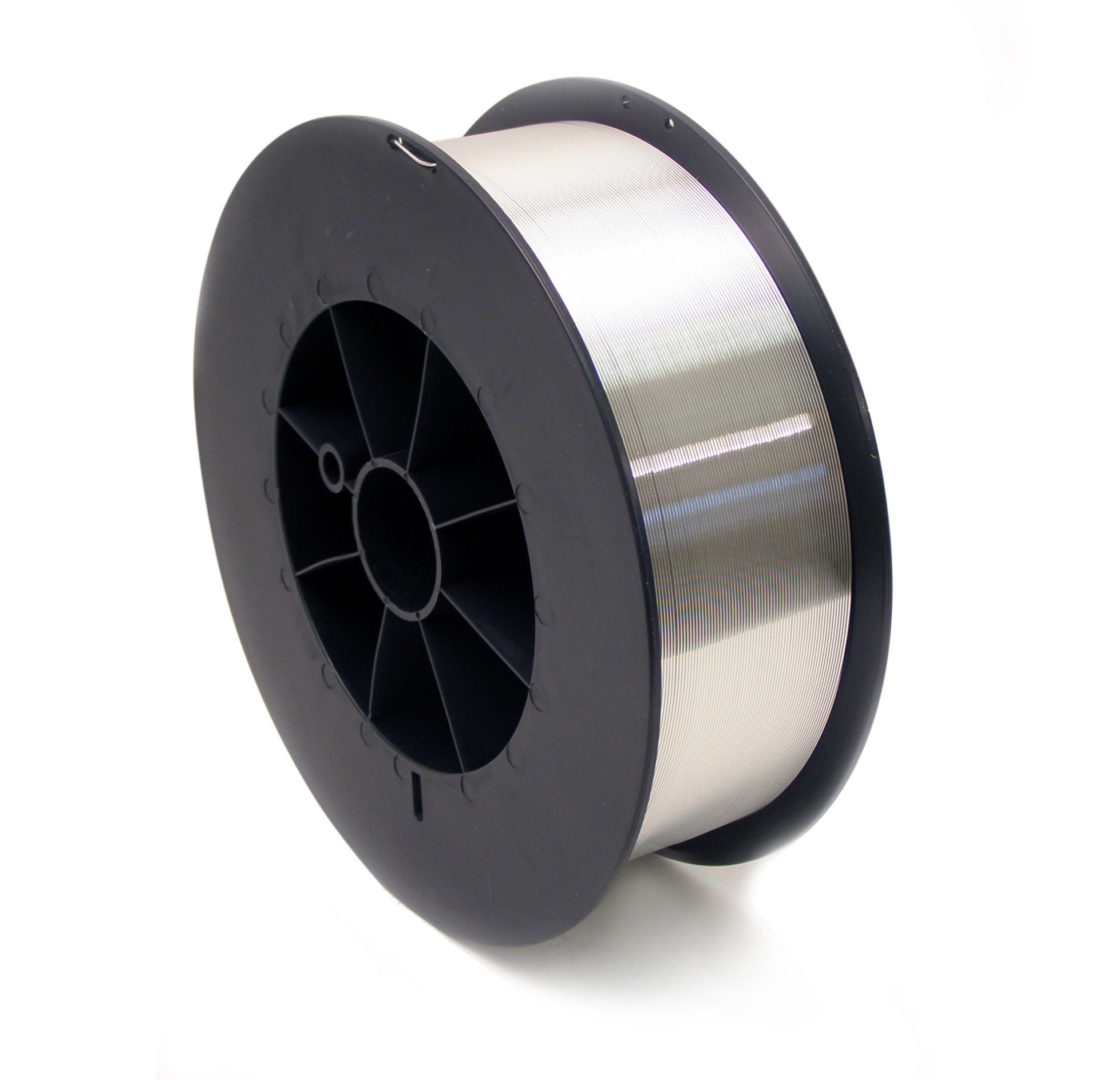

Stainless Steel 309LSi MIG Welding Wire 15kg Spool

Orders OVER £60 (Excluding VAT)

Orders UNDER £60 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Stainless Steel 309LSi MIG Welding Wire 15kg Spool

€188.82 – €199.44Price range: €188.82 through €199.44

Stainless Steel 309LSi MIG Welding Wire is a premium welding solution designed for high-quality welding of stainless steel and dissimilar metals.

Orders OVER £60 (Excluding VAT)

Orders UNDER £60 (Excluding VAT)

Republic of Ireland: £8.50 (+VAT)

UK Mainland: £8.50 (+VAT)

See our Shipping & Returns page for more information

Have a Question? Ask a Specialist

Low Prices

Price match guarantee

Wide range of products available

Always the correct part

In-House Experts.

We know our products

Easy Returns.

Quick & Hassle Free

Stainless Steel 309LSi MIG Welding Wire – 15kg Spool

Stainless Steel 309LSi MIG Welding Wire is a premium welding solution designed for high-quality welding of stainless steel and dissimilar metals. This innovative product combines advanced metallurgical technology with precision manufacturing to offer unmatched welding performance, making it an ideal choice for a wide range of applications in industries such as construction, automotive, food processing, and more.

Key Features of 309LSi stainless steel mig wire:

- Alloy Composition: The 309LSi variant is enriched with a higher silicon content compared to its 309L counterpart. This modification enhances the fluidity of the weld pool, resulting in smoother bead appearance and reduced spatter, making it easier to achieve clean, aesthetically pleasing welds with exceptional precision.

- Versatility in Welding Dissimilar Metals: Specifically engineered for welding stainless steel to other types of steel, the 309LSi wire is the go-to choice for projects that involve dissimilar metals. Its balanced chemistry helps in preventing cracking and ensures the integrity of the weld, even when joining stainless steel to carbon or low-alloy steels. This capability is crucial in applications where strength, durability, and corrosion resistance across different metal types are paramount.

- High Corrosion Resistance: The alloy composition of the 309LSi welding wire provides excellent resistance to general corrosion, oxidation, and the harsh conditions encountered in various industrial environments. This makes it suitable for use in settings exposed to chemicals, high temperatures, and corrosive elements, ensuring the longevity and reliability of the welded structures.

- Improved Welding Performance: The addition of silicon improves the arc stability and reduces the occurrence of weld defects, allowing for smoother operation and enhanced control over the welding process. This leads to higher productivity and reduced rework, making it an efficient choice for both manual and automated welding operations.

- Applications: The versatility and superior properties of the Stainless Steel 309LSi MIG Welding Wire make it ideal for a wide range of applications, including but not limited to, fabricating and repairing equipment in the chemical processing industry, joining of stainless steel to carbon or low-alloy steel structures, and construction of components subjected to high temperatures or corrosive environments.

Unleash the Power of Silicon:

309LSi surpasses standard 309L wires with its enhanced silicon content (0.5-1.00%). This game-changer unlocks a range of benefits:

- Unmatched Wetting and Washing: Experience exceptionally smooth bead profiles with minimal spatter. Achieve flawless aesthetics and reduced grinding for superior productivity.

- Superior Arc Stability: Enjoy a cleaner, more focused arc that minimizes spatter and rework, boosting your welding efficiency.

- Excellent Penetration: Achieve deeper weld penetration with consistent heat distribution, ideal for thick materials and demanding joints.

Benefits of 309LSi mig wire:

- Enhanced Productivity: The superior arc stability and smooth welding characteristics of the 309LSi wire reduce downtime and increase welding speed, directly contributing to higher productivity and efficiency in welding operations.

- Superior Aesthetic Finish: The improved fluidity of the weld pool results in a smooth, uniform weld bead, minimizing post-weld finishing work and enhancing the overall appearance of the welded structure.

- Adaptability: Whether it’s a complex fabrication project involving multiple metal types or routine maintenance work, the 309LSi welding wire adapts to various welding challenges, offering reliable performance across a broad spectrum of applications.

- Long-Term Reliability: The corrosion-resistant properties of the wire ensure that welded joints remain robust and durable over time, even in harsh industrial environments, contributing to the longevity of the welded structures and reducing the need for frequent repairs.

Stainless Steel 309LSi MIG Welding Wire stands out as a superior welding solution for stainless steel and dissimilar metals. Its advanced alloy composition, combined with enhanced welding properties, offers unparalleled performance, versatility, and reliability. Whether you’re tackling a demanding industrial project or a simple repair job, this welding wire delivers consistent results, making it an invaluable tool in your welding arsenal.

Read our Blog – Stainless Steel Mig Welding Wire

Miller Welding offers suggestions on how to improve your Stainless Steel Mig Welding.